Differential transfer mechanism for battery manufacturing

A transfer mechanism and battery technology, which can be applied to conveyor objects, transportation and packaging, etc., can solve the problems of complicated equipment, large size, and size limitations, and achieve the effect of reducing equipment costs, simplifying equipment mechanisms, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

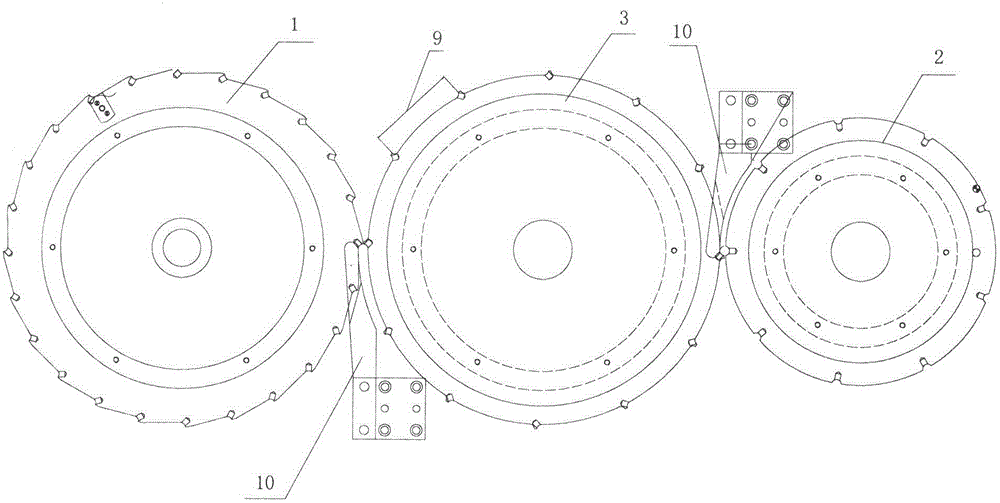

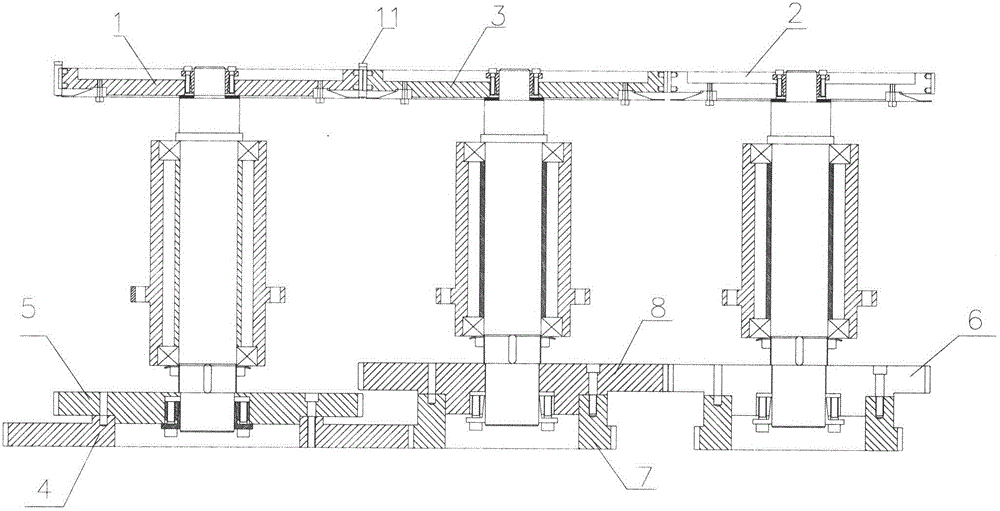

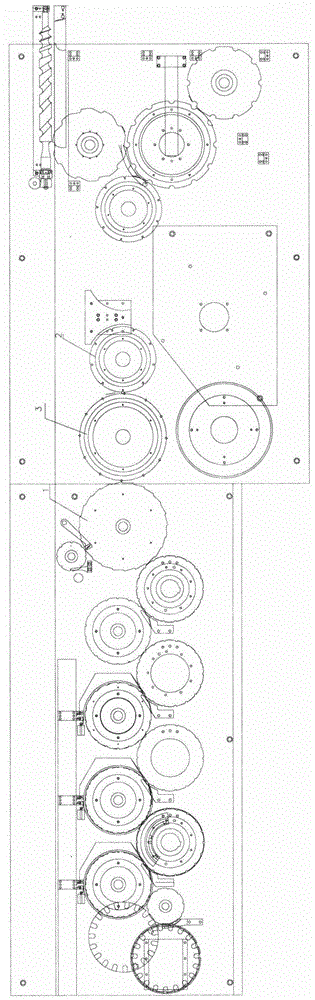

[0016] Such as figure 1 , 2 As shown, the differential transfer mechanism for battery manufacturing of the present invention includes a workpiece disc 1 after the collar, a workpiece disc 2 before scoring and a transfer transition disc 3, and a differential is set on the rotating shaft of the workpiece disc 1 after the collar. The high-speed driving gear 4 and the bezel side gear 5, the engraving side gear 6 is set on the rotating shaft of the workpiece disc 2 before marking, the differential driven gear 7 and the transition gear 8 are set on the rotating shaft of the switching transition plate 3, and the differential driving Gear 4 meshes with differential driven gear 7, and transition gear 8 meshes with engraved side gear 6; the number of teeth of differential driving gear 4 is twice that of differential driven gear 7, and the modulus of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com