Automotive loading gate

A technology for gates and automobiles, applied in the directions of transportation and packaging, loading/unloading, etc., can solve the problems of easy scattering, large dust, distance adjustment, etc., to avoid coal dust flying, good coal leveling and dust suppression, and effective dustproof. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

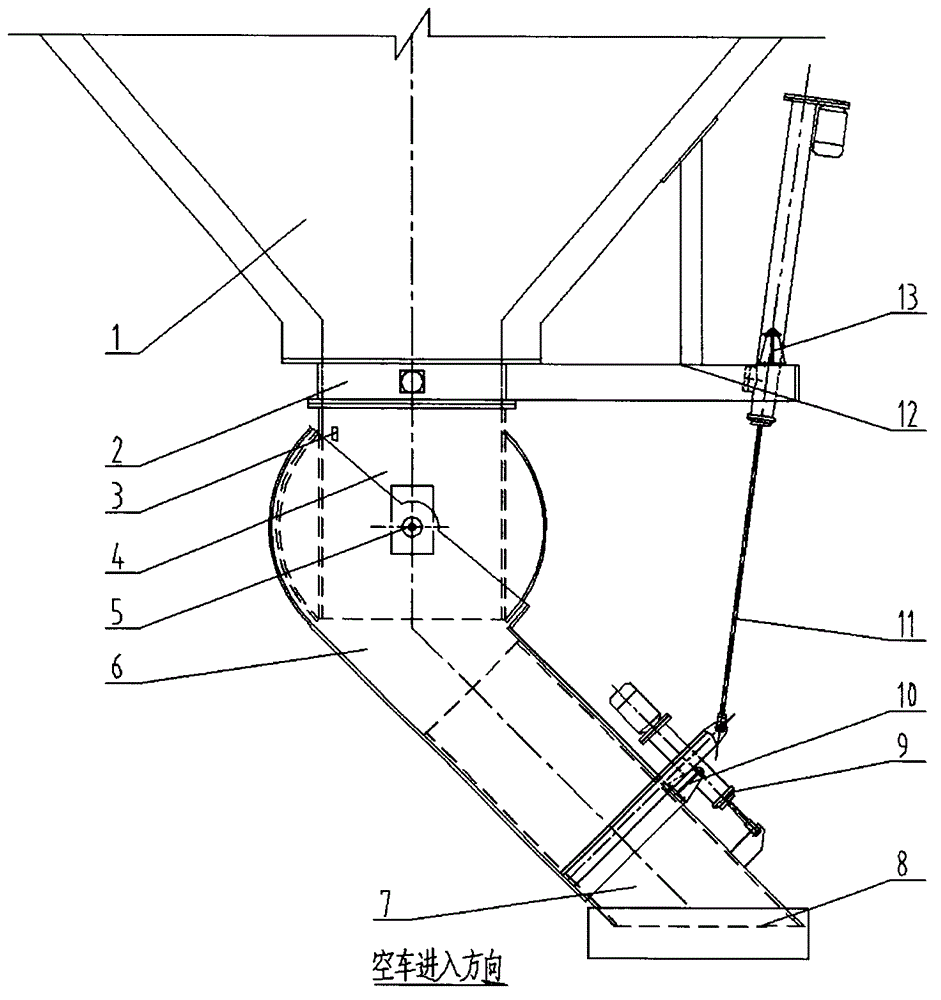

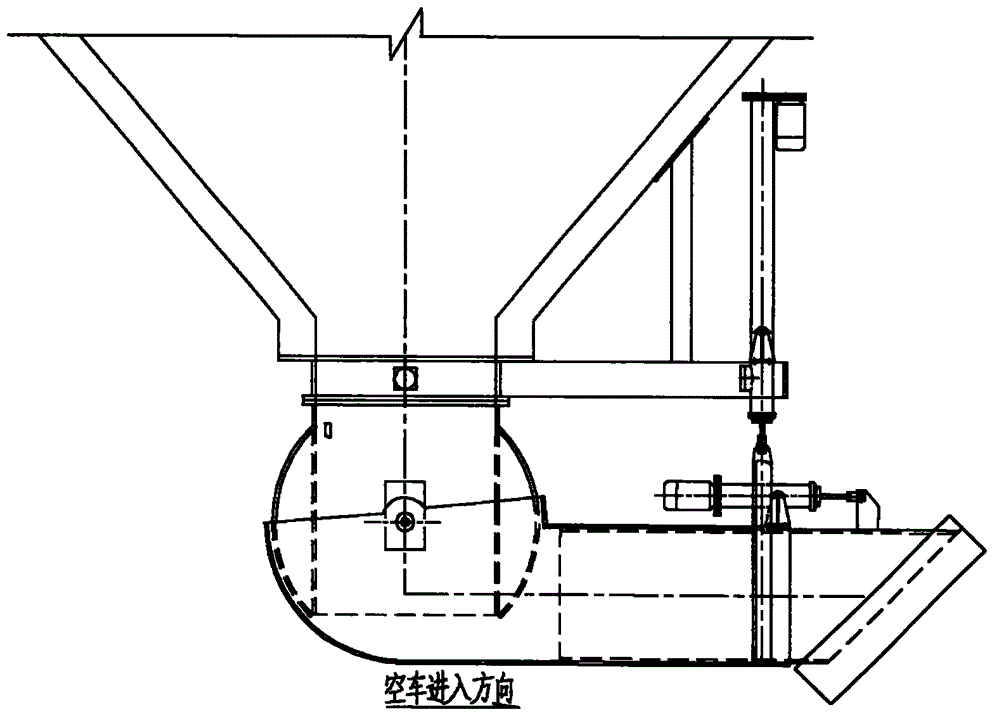

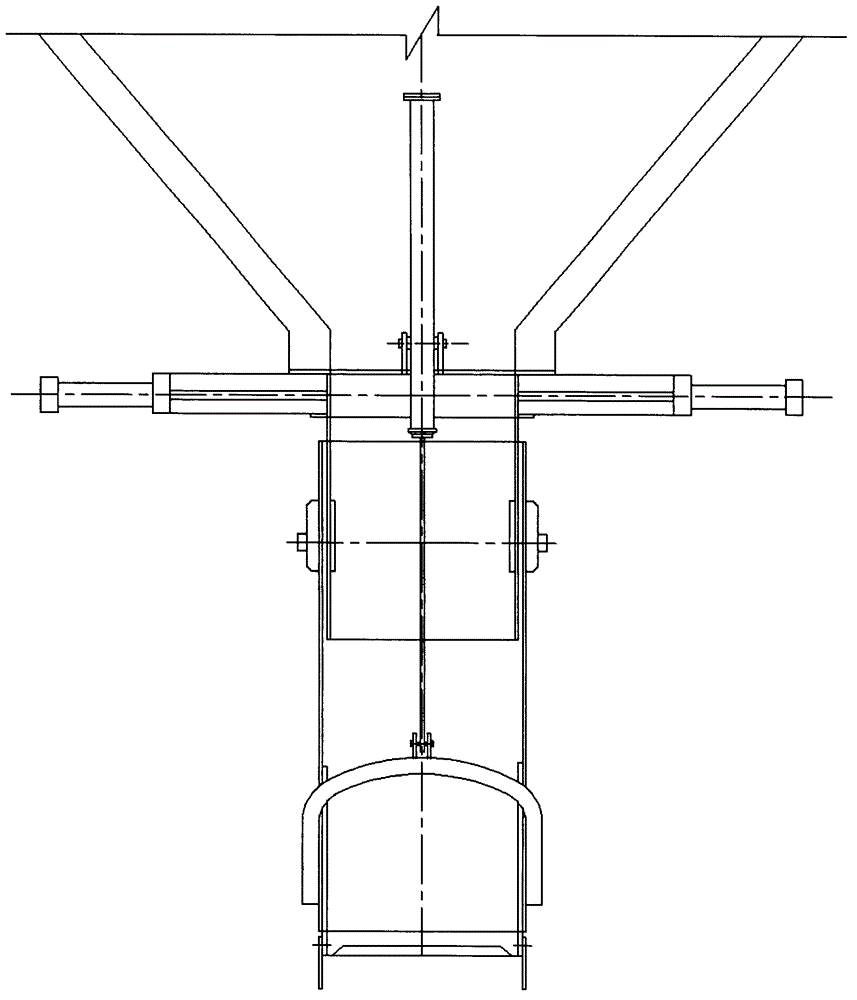

[0027] figure 1 Schematic diagram when loading for the present invention, the steps are as follows:

[0028] (1) After the empty car is aligned, the swing cylinder 11 pushes the swing chute 6 to rotate around the rotating shaft 5, and puts down the swing chute 6. The angle between the swing chute 6 and the horizontal direction depends on the particle size of the material, water content, and the vehicle load. The speed of the vehicle is adjusted to control the flow rate of the material.

[0029] (2) The telescopic oil cylinder 9 functions to release the telescopic chute 7, so that the discharge end of the telescopic chute 7 is close to the carriage.

[0030] (3) Slowly open the hydraulic plate gate 2, the opening of the gate is small first and then large, and the opening of the gate is controlled according to the load and driving speed of the vehicle, so as to control the amount of material.

[0031] (4) After the initial loading reaches a certain height, the telescopic chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com