Horizontal wedging pull rod assembly and using method thereof

A tie rod and horizontal technology, which is applied in the preparation of building components on site, the connection parts of formwork/formwork/work frame, construction, etc., can solve the problem that the position relationship between the steel skeleton and formwork in the mold cannot be guaranteed, and the construction quality cannot be obtained. More comprehensive protection, damage to corrugated rods and other issues, to achieve the effect of precise sealing, beautiful appearance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above-mentioned features and advantages of the present invention more obvious and easy to understand, the following specific embodiments are given and the accompanying drawings are described in detail as follows, but the present invention is not limited thereto.

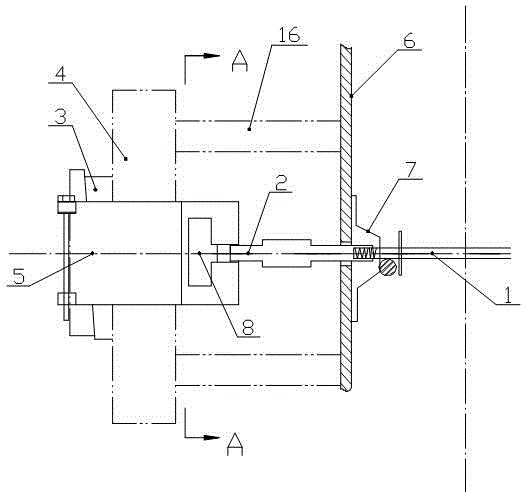

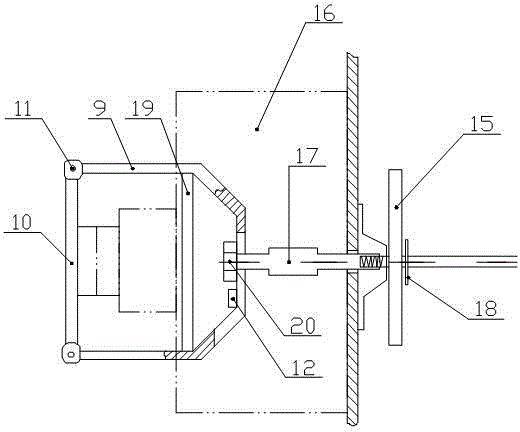

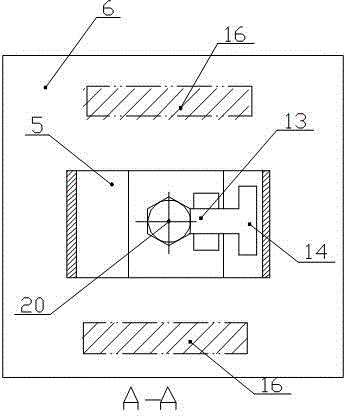

[0036] With reference to legends 1 to 4, the horizontal wedge tension rod assembly of the present invention includes an in-mold positioning rod 1 for embedding in concrete, a connecting rod 2 and a wedging frame body 5 for piercing the wedge block 3 and the first corrugated rod 4 , the end of the in-mold positioning rod 1 is provided with a cover body 7 with an opening on the inner wall surface of the template 6, the in-mold positioning rod 1 extends into the end of the cover body 7 and the connecting rod 2 passing through the template 6 The inner ends are screwed to each other, and the outer end 20 of the connecting rod 2 is sleeved on the engaging groove 8 on the wedging frame 5 . It sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com