Mechanical intelligent adaptive two-gear multi-cam automatic speed change driver

An automatic shifting and self-adaptive technology, applied in mechanical equipment, transmissions, belts/chains/gears, etc., to ensure sensitivity, save energy and reduce consumption, and eliminate shifting frustration and jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

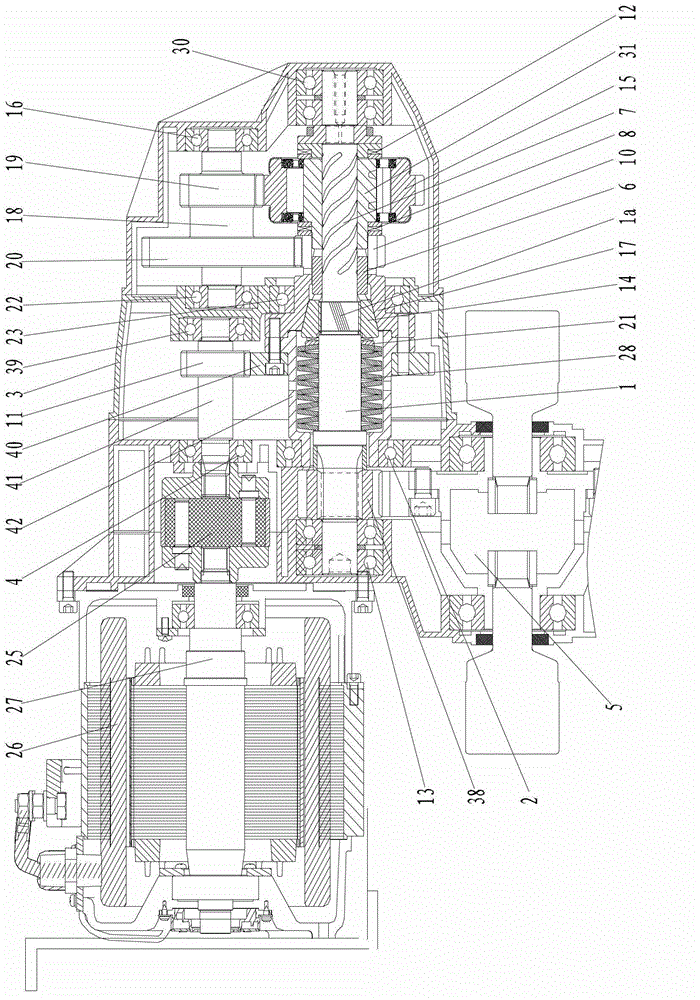

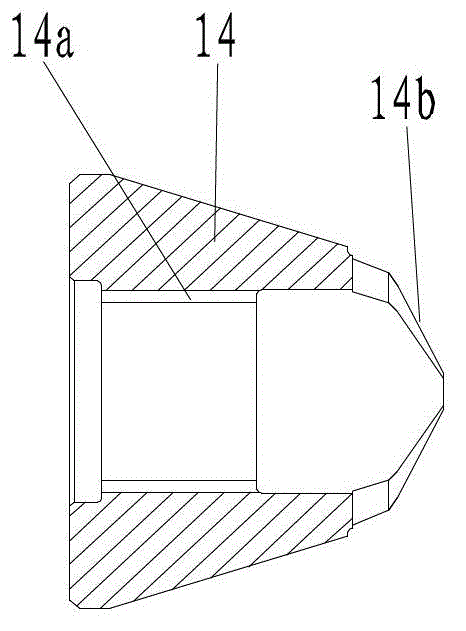

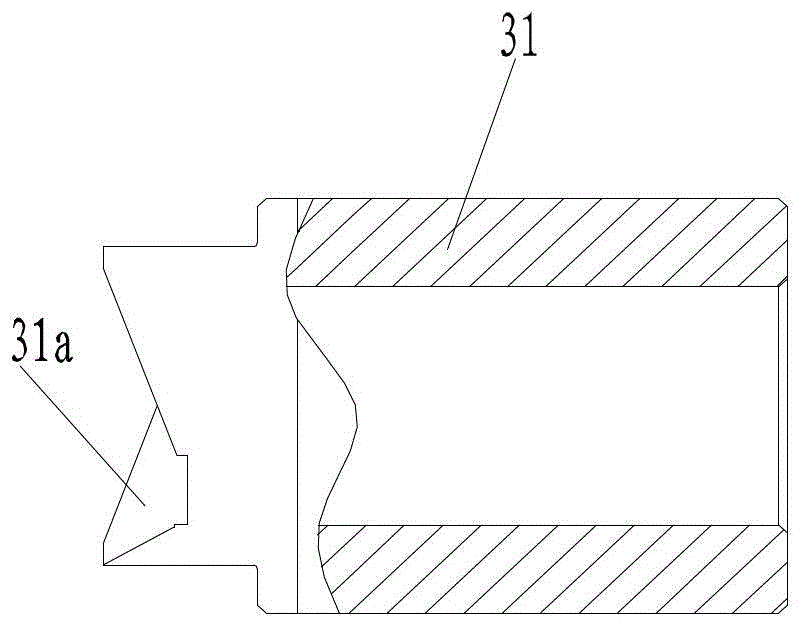

[0037] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 It is a schematic diagram of the structure of the axial outer taper sleeve of the torus, image 3 It is a structural schematic diagram of the inner ring of the overrunning clutch, Figure 4 Schematic diagram of the oil passage structure on the tapered surface of the axial outer tapered sleeve of the annular body; Figure 5 It is a structural schematic diagram of the middle cam sleeve; Figure 6 It is a schematic diagram of cam expansion at both ends of the middle cam sleeve; Figure 7 Schematic diagram of the structure of the overrunning clutch; Figure 8 It is a schematic diagram of the support column, the support piece and the reed, Figure 9 It is a schematic diagram of the reed structure, Figure 10 It is a schematic diagram of an axial partial sectional structure of an overrunning clutch, as shown in the figure: the power device of this embodiment is a motor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com