Using method of reciprocating eccentricity prevention oil sealing device

An eccentric, sealing sleeve technology, used in engine sealing, engine components, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

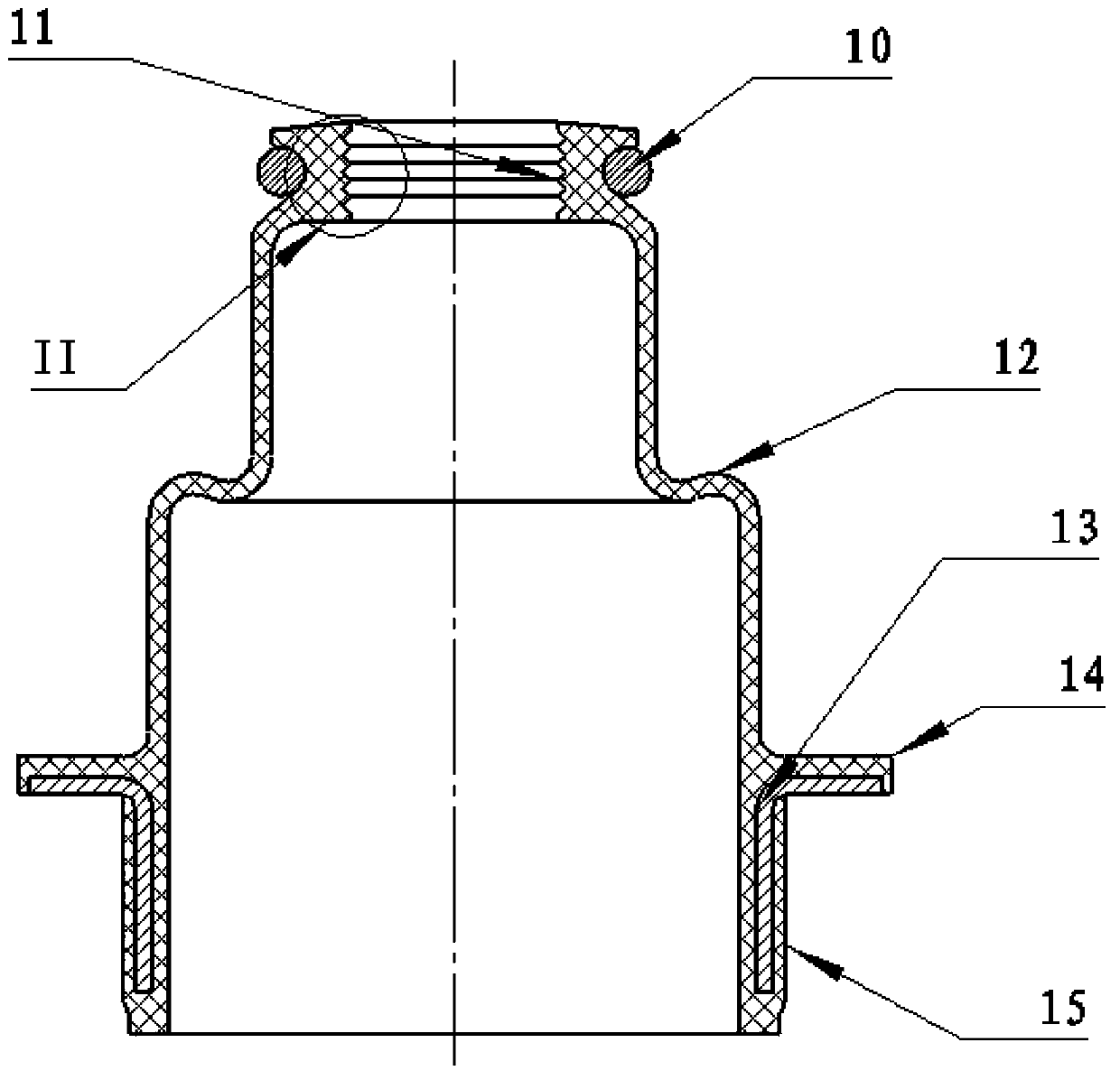

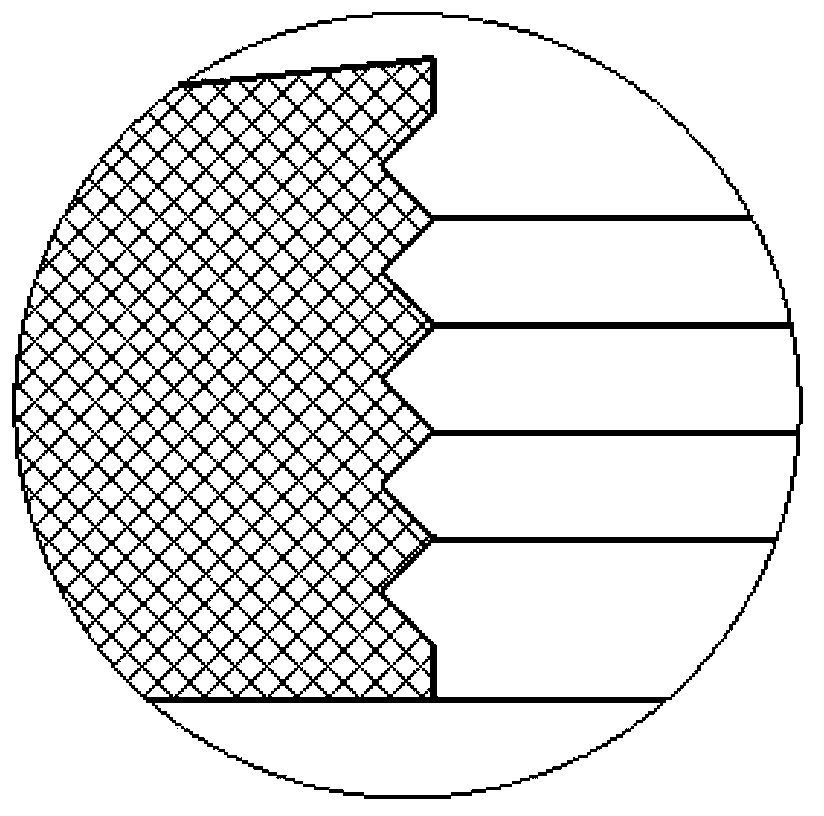

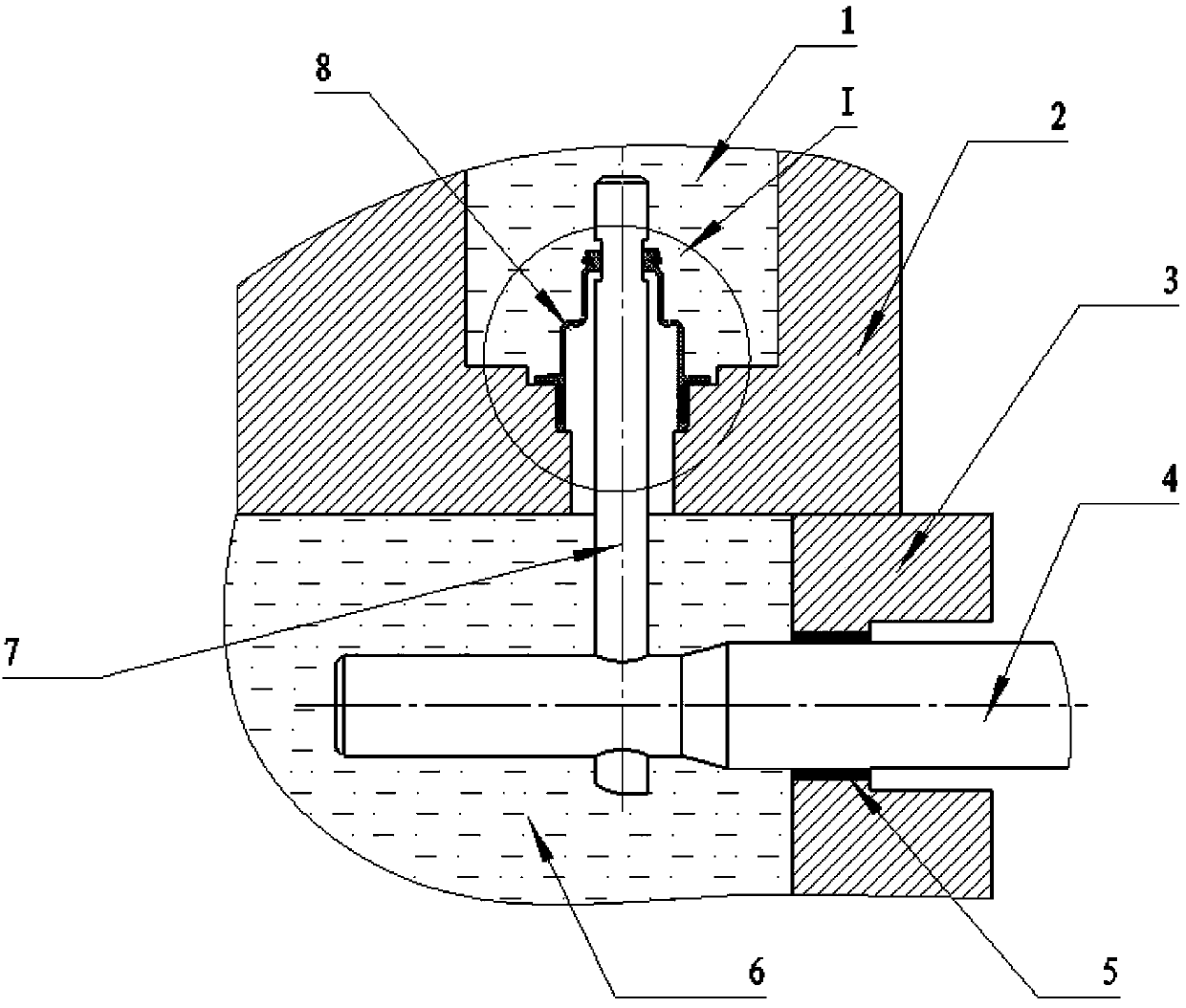

[0024] Such as Figure 1 to Figure 4 As shown, an oil sealing device for reciprocating eccentricity resistance includes a sealing sleeve 8 set as a long cylindrical stepped shape, and the sealing sleeve 8 is provided with a rounded groove 12 at a position where the steps are distributed; the wall of the sealing sleeve 8 The thickness is 1.5mm; the sealing sleeve 8 is provided with a sealing lip 11; the bottom of the sealing sleeve 8 is provided with a rigid frame 13 in a flanging structure 14, and a sealing rubber body 15 is provided on the outside of the frame 13; The sealing lip 11 is set to be wavy; the sealing lip 11 is set to form an interference fit with the connecting rod 7; the sealing rubber body 15 outside the frame 13 is set to form an interference fit with the casting hole structure.

[0025] The method of using the oil sealing device for re-resistant eccentricity includes the following steps:

[0026] In the first step, install the shaft 4 into the second casting 3, ...

Embodiment 2

[0032] The difference is that the wall thickness of the sealing sleeve is 1 mm, and the sealing lip 11 is set in a sawtooth shape.

Embodiment 3

[0034] The same as the first embodiment, the difference is that the wall thickness of the sealing sleeve is 2 mm.

[0035] In this way, when working, the method for using the reciprocating eccentricity-resistant oil sealing device of the present invention is that the first casting 2 forms an oil cavity 1, which is filled with gear oil, and the second casting 3 forms an oil cavity 6, which has Gear oil, connecting rod 7 is connected with shaft 4. Shaft 4 drives connecting rod 7 to reciprocate up and down, and has a 10° swing. There is a large gap between connecting rod 7 and the hole of first casting 2, and sealing sleeve is needed here. 8 is sealed to prevent the oil in the two oil chambers from permeating each other; the gap between the shaft 4 and the first casting 2 is sealed by the oil seal 5. When assembling, the shaft 4 is installed in the second casting 3, and then the sealing sleeve 8 is installed in the second casting 3. In the seat hole of a casting 2, the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com