Joint assembly

An assembly and joint body technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, hose connection devices, etc., can solve problems such as easy oil leakage, loose connection devices, and difficult installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

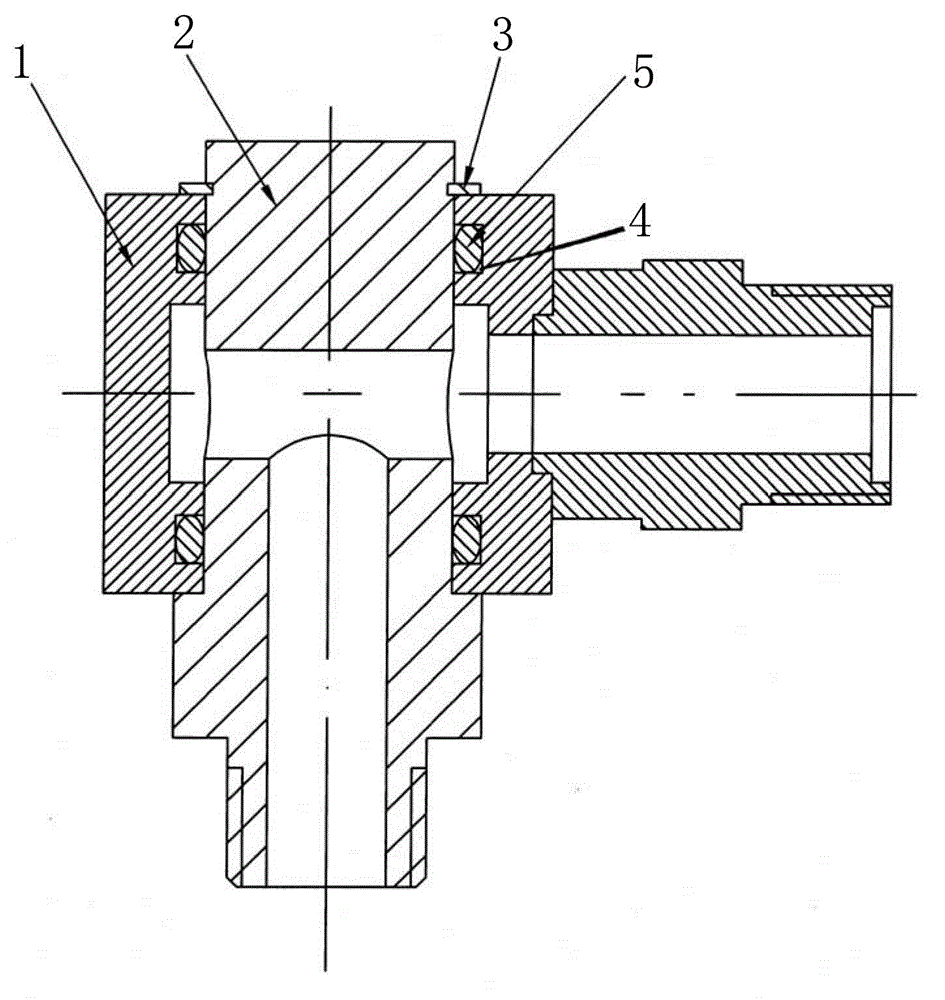

[0009] like figure 1 As shown, the present invention is provided with a cylinder joint body 2 in the oil return pipe joint body 1, and the cylinder joint body 2 and the oil return pipe joint body 1 are connected together by a circlip 3 for the shaft, and the oil return pipe joint body 1 and the cylinder body The pipelines of the joint body 2 are connected, and the upper and lower contact surfaces of the oil return pipe joint body 1 and the cylinder joint body 2 are respectively provided with annular sealing grooves 4 , and O-rings 5 are arranged in the annular sealing grooves 4 . Through the above settings, the cylinder joint body 2 of the present invention is connected to the cylinder head of the piston cylinder, the oil return pipe joint body 1 is connected to the oil return hose, and the hydraulic oil flows through the inner hole of the cylinder joint body 2 through the oil return pipe joint body 1. The oil return hose, when the cargo box is lifted, the oil return pipe jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com