Method and device for measuring flatness of backplane of liquid crystal display device

A liquid crystal display device and flatness technology, which can be applied to measurement devices, instruments, etc., can solve problems such as poor quality and deviation of liquid crystal display devices, and achieve the effect of avoiding unqualified liquid crystal display devices from leaving the factory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

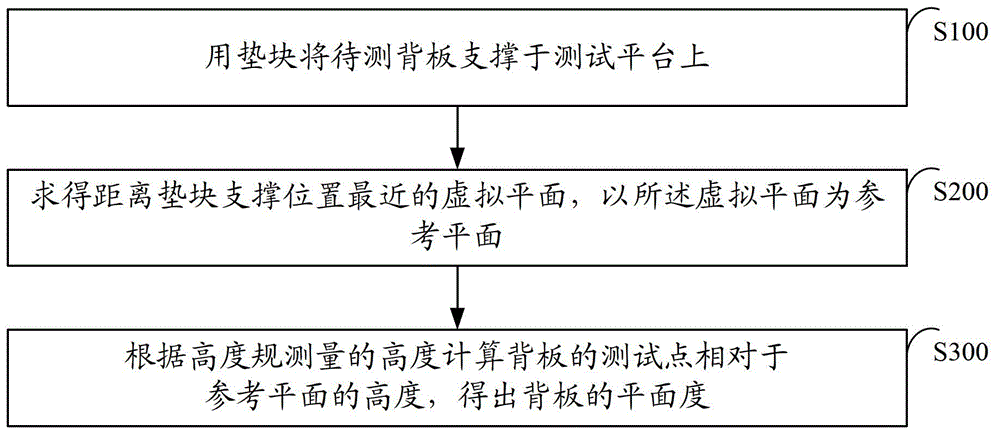

[0060] Examples of the present invention are Figures 2 to 5 shown. The steps of embodiment method are as Image 6 shown.

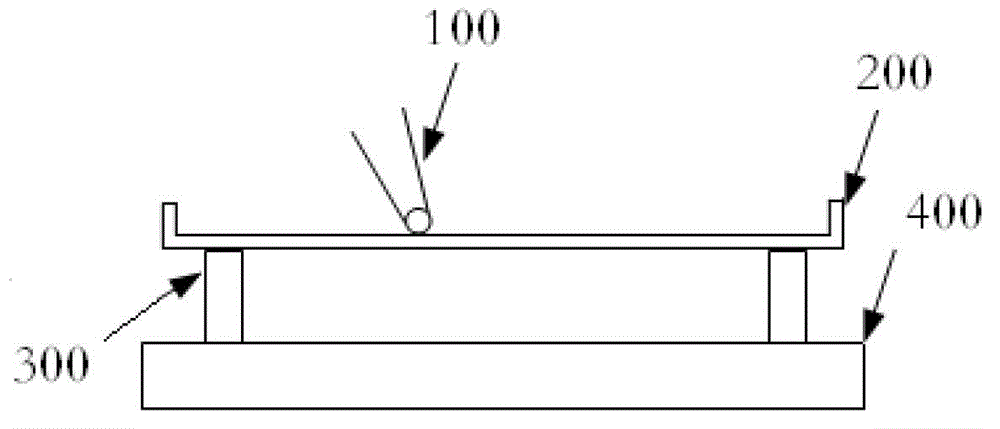

[0061] In step S601 , the backplane 200 to be tested is supported on the test platform 400 by the block 300 .

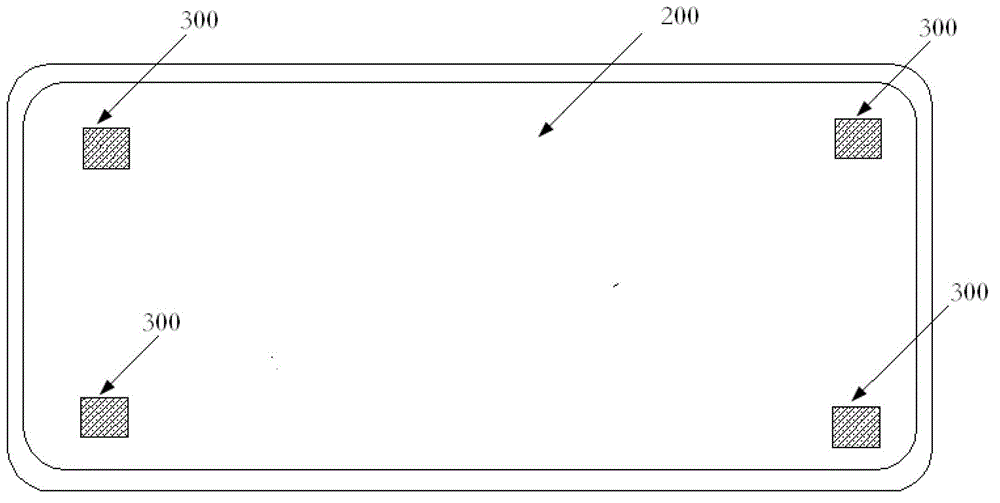

[0062] In this embodiment, the test platform 400 is a grade A or AA marble platform, and there are four spacers 300, and the height difference between them is less than 0.05 mm. Such as figure 2 As shown, adjust the position of the spacer 300 so that it is at the four corners of the backboard 200 , and place the backplane 200 flat on the plane formed by the spacer 300 . The schematic diagram of the supporting position of the cushion block 300 in the backplane 200 in this embodiment is as follows image 3 shown.

[0063] Step S602, arrange measurement points on the surface of the backplane 200, and select a reference point 0.

[0064] The measurement points are included in the support positions of the pads 300 of the backplane 200 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com