Device for testing performance of cohesive soil sample and testing method thereof

A testing device and cohesive soil technology, which is applied in measuring devices, suspension and porous material analysis, scientific instruments, etc., can solve the problems of limiting the accuracy of heavy metal pollutants migration parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

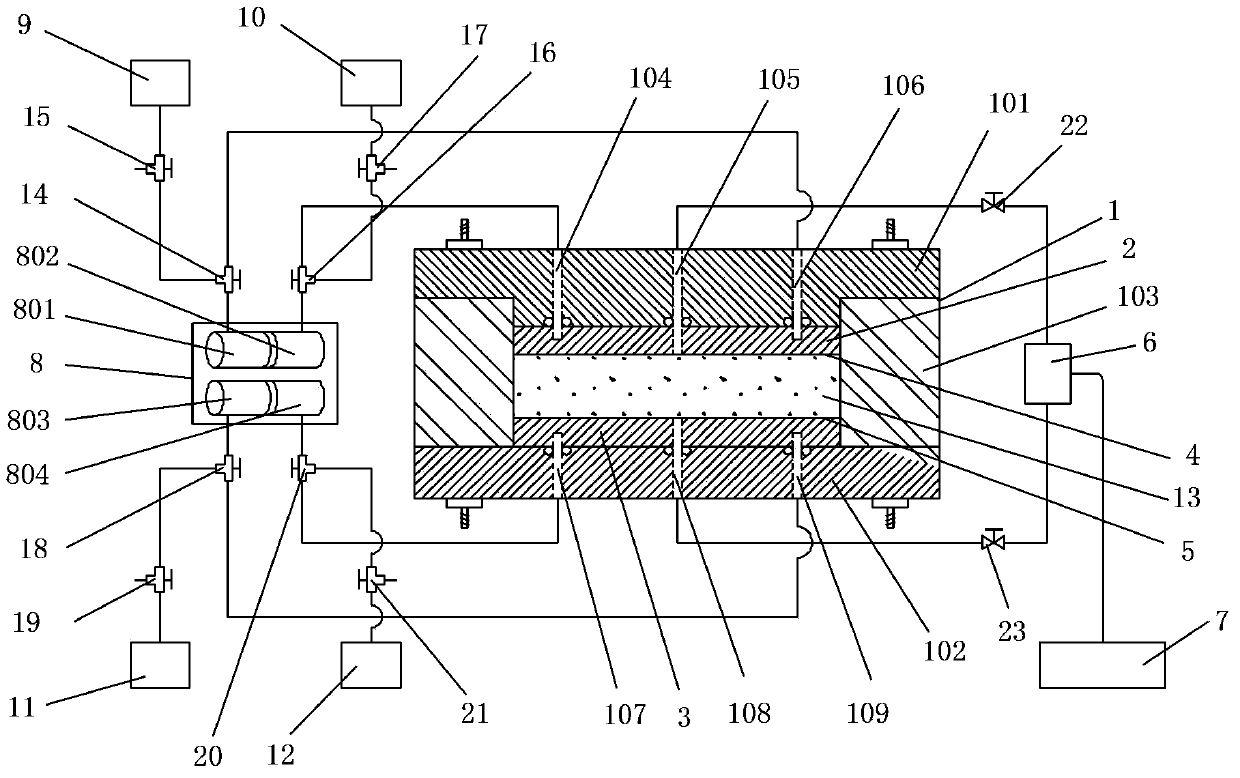

[0036] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] The cohesive soil sample mentioned in the present invention may be engineering barrier materials such as cohesive soil, compacted clay (CCL), geosynthetic clay liner (GCL). The performance testing device of the invention is used to measure the film efficiency coefficient, effective diffusion coefficient and retardation factor performance of a clay sample under the action of a metal ion solution.

[0038] Such as figure 1 As shown, a performance testing device for a cohesive soil sample of the present invention includes a sample box 1, an upper permeable stone 2, a lower permeable stone 3, an upper filter paper 4, a lower filter paper 5, a differential pressure sensor 6, a data acquisition Instrument 7, precision syringe pump 8, first liquid storage tank 9, second liquid storage tank 10, third liquid storage tank 11 and fourth liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com