Structured light-based surface defect high-speed detection system and detection method thereof

A detection system and structured light technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of vehicle body bumps, damages, acceleration highways and railways, etc., to achieve the effect of convenient observation, simple image processing method, and avoiding detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

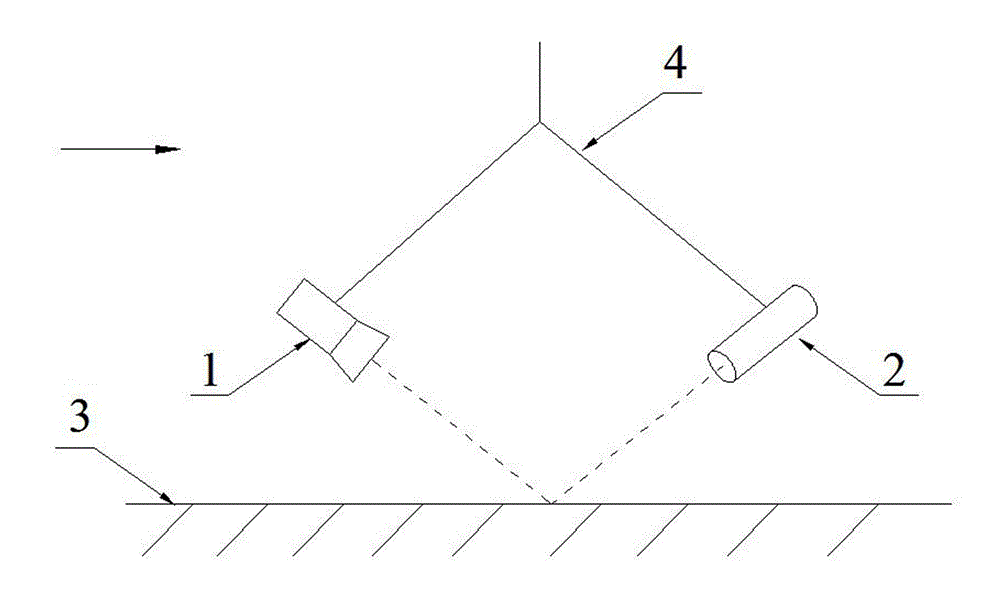

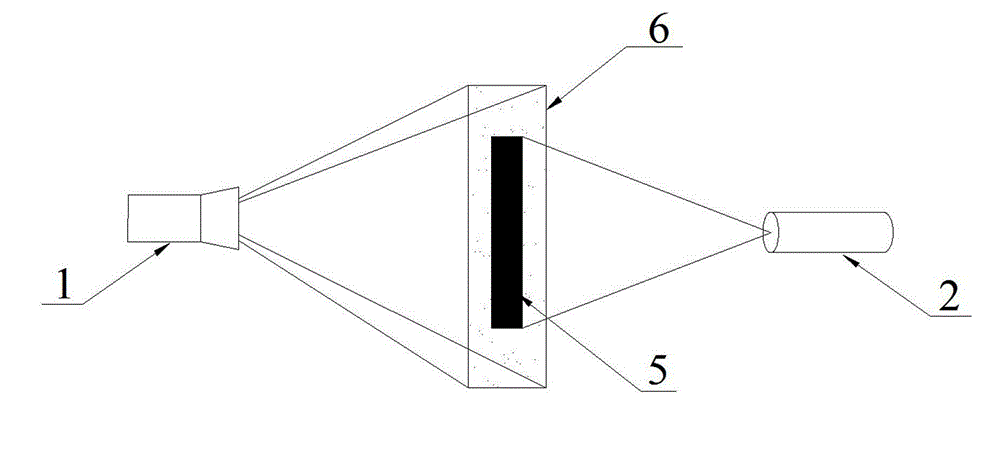

[0033] refer to figure 1 and figure 2 , the high-speed detection system for surface defects based on structured light of the present invention includes: a high-speed camera 1, a structured light source 2, a light shield (not shown) arranged on the periphery of the high-speed camera 1 and the structured light source 2, and a high-speed camera 1 that receives and processes Processor (not shown) for incoming image information.

[0034] Wherein, the optical axis of the high-speed camera 1 forms a depression angle with the surface to be measured 3; the structured light source 2 is arranged in front of the high-speed camera 1, and the optical plane of the structured light source 2 forms an angle greater than or equal to 90° with the optical axis of the high-speed camera 1. Considering that after the detection system is installed on different det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com