Battery

A battery and cell technology, applied in secondary batteries, battery pack components, circuits, etc., can solve problems such as uneven internal temperature, poor battery performance, and uncontrollability, to ensure working performance, improve cycle performance, eliminate The effect of temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] as attached Figure 1-5 It is a structural schematic diagram of a battery of the present invention.

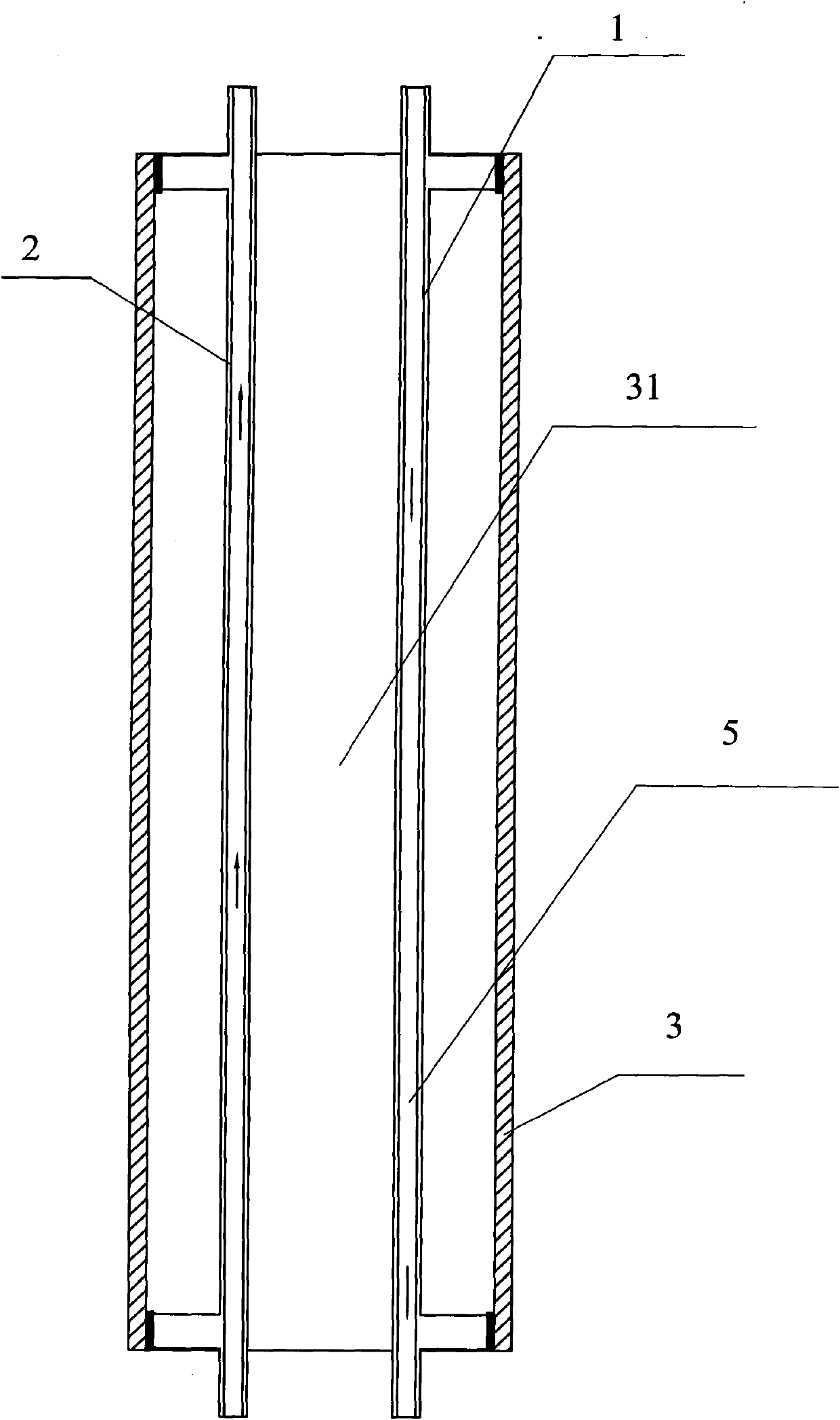

[0044] After placing the parallel positive heat pipes 1 and negative heat pipes 2 in parallel and at intervals, injection molding is performed on their surfaces to obtain an insulating core 3 with exposed ends of the positive heat pipes 1 and negative heat pipes 2 . The positive heat pipe 1 and the negative heat pipe 2 are filled with insulator 31 at the same time, and the positive heat pipe 1 and the negative heat pipe 2 are located in the insulating core 3, that is, the surface of the positive heat pipe 1 and the negative heat pipe 2 is covered with an insulating layer.

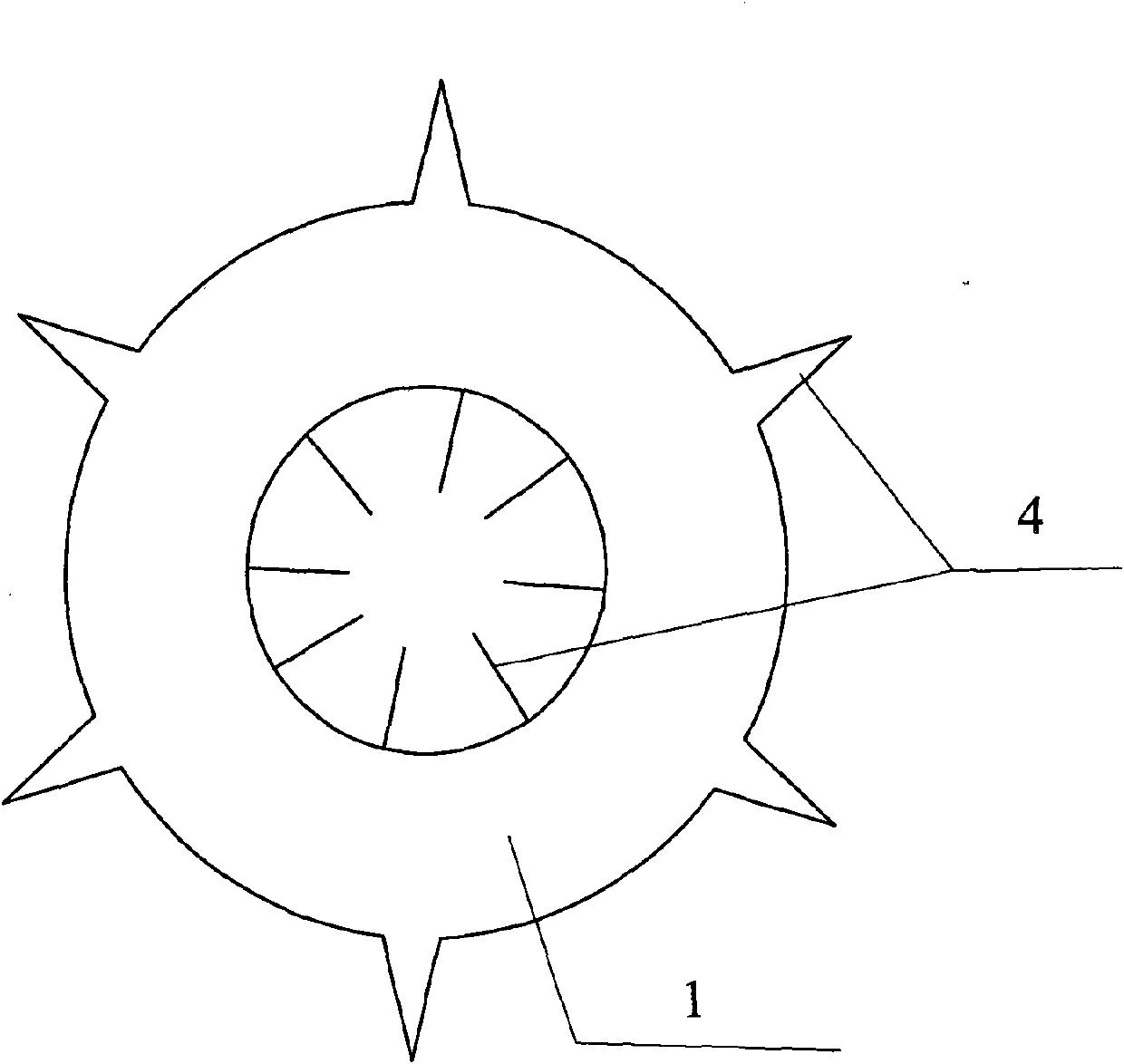

[0045] The quantity of the positive heat pipe 1 and the negative heat pipe 2 is not particularly limited in the present invention, and can be designed according to the size of the positive heat pipe 1 and the negative heat pipe 2 and the size of the electric core 6, etc. The shape of the positive el...

Embodiment 2

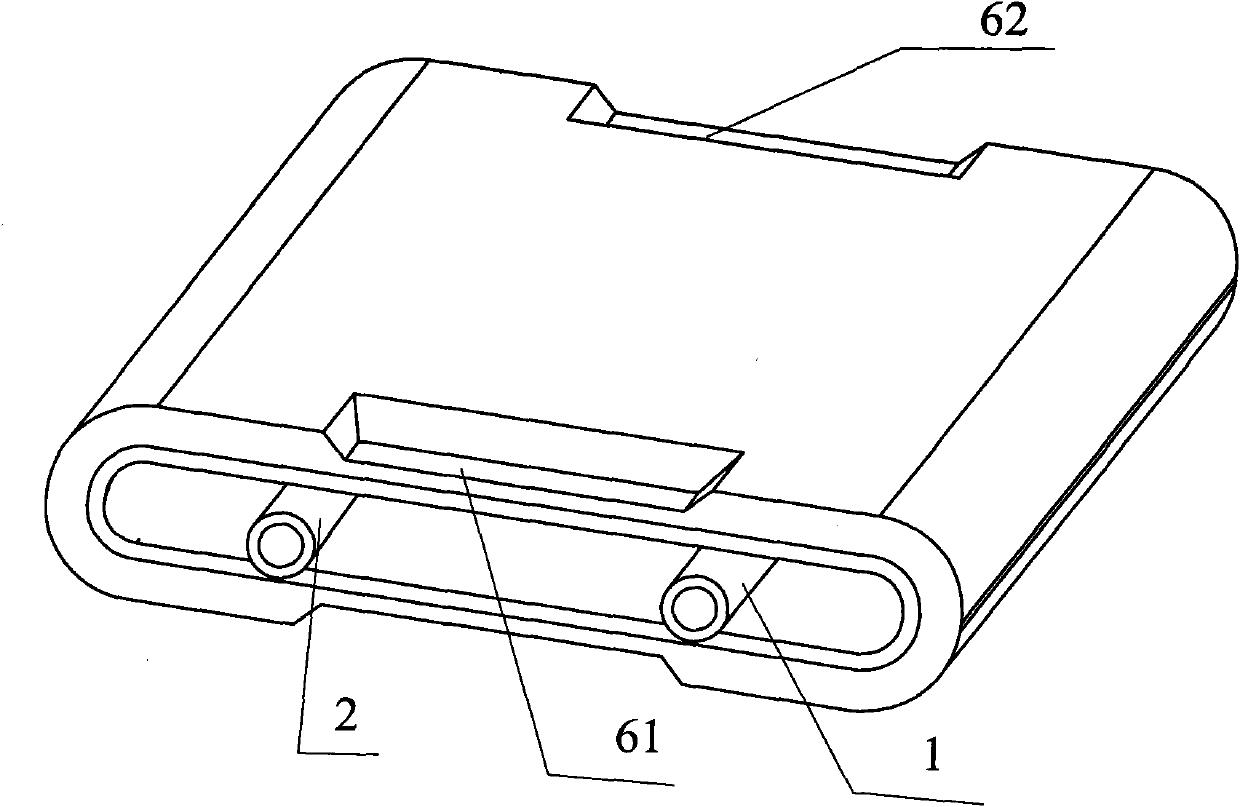

[0054] Such as Figure 6-8 As shown, the battery was prepared in the same manner as in Example 1, except that the positive heat pipe 1 and the negative heat pipe 2 were both made into U-shaped tubes, and the U-shaped bottoms of the U-shaped tubes were placed opposite to each other at intervals. Injection molding to obtain the insulating core member 3 in which the ends of the positive heat conduction pipe 1 and the negative heat conduction pipe 2 are exposed. The positive heat pipe 1 and the negative heat pipe 2 are filled with insulator 31 at the same time, and the positive heat pipe 1 and the negative heat pipe 2 are located in the insulating core 3, that is, the surface of the positive heat pipe 1 and the negative heat pipe 2 is covered with an insulating layer.

[0055]The electric core 6 is wound on the outer surface of the insulating core 3, both ends of the positive heat pipe 1 extend from one end of the electric core 6, and both ends of the negative heat pipe 2 extend f...

Embodiment 3

[0060] Such as Figure 9 As shown, the battery is prepared by the same method as in Example 2, except that a power supply pump and a temperature control system are set between the ends of the two positive electrode heat pipes 1 protruding from one end of the battery in Example 2. The pump, temperature The two ends of the control system and the positive electrode heat pipe 1 are connected through the delivery circulation pipeline 10 of the heat transfer medium 5, and the temperature control system includes a temperature sensing unit capable of inducting the temperature of the heat transfer medium circulating in circulation, such as an induction probe, and a temperature sensing unit capable of controlling the temperature of the heat transfer medium in circulation. The control unit for heating and cooling by the heat-conducting medium. The control unit can include heating fins and radiators and an intelligent control center that controls the work of the heating fins and radiators....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com