Travelling mechanism of inspection robot for realizing obstacle crossing

A line inspection robot and walking mechanism technology, applied in the field of robotics, can solve the problems of inability to truly realize automatic line inspection operations, affecting the efficiency of line inspection work, relying on manual remote control, etc., to achieve fast obstacle walking speed, light weight, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

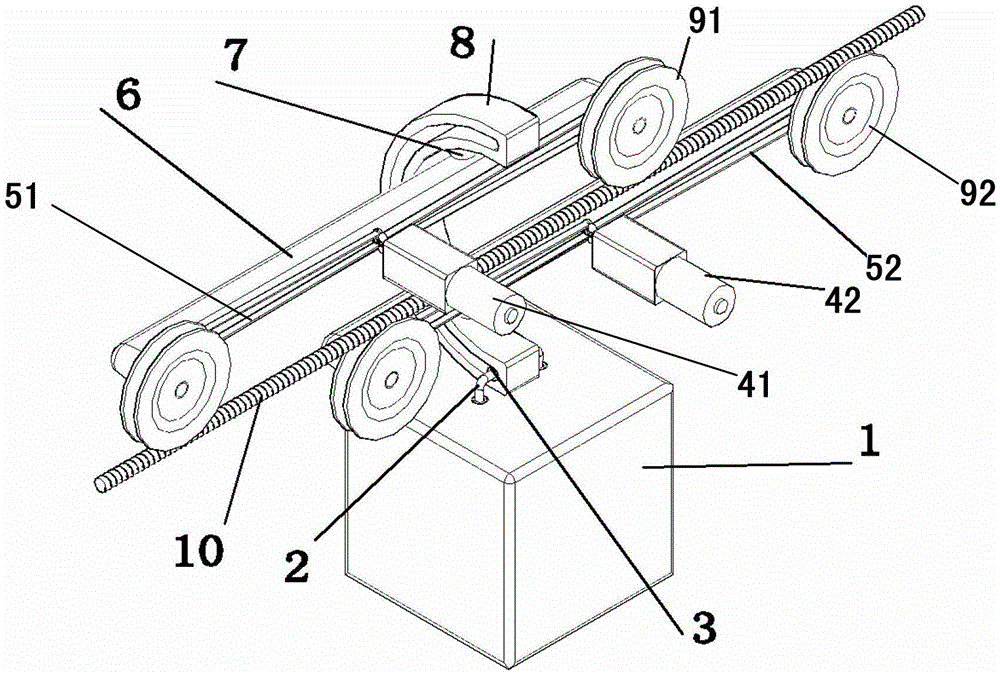

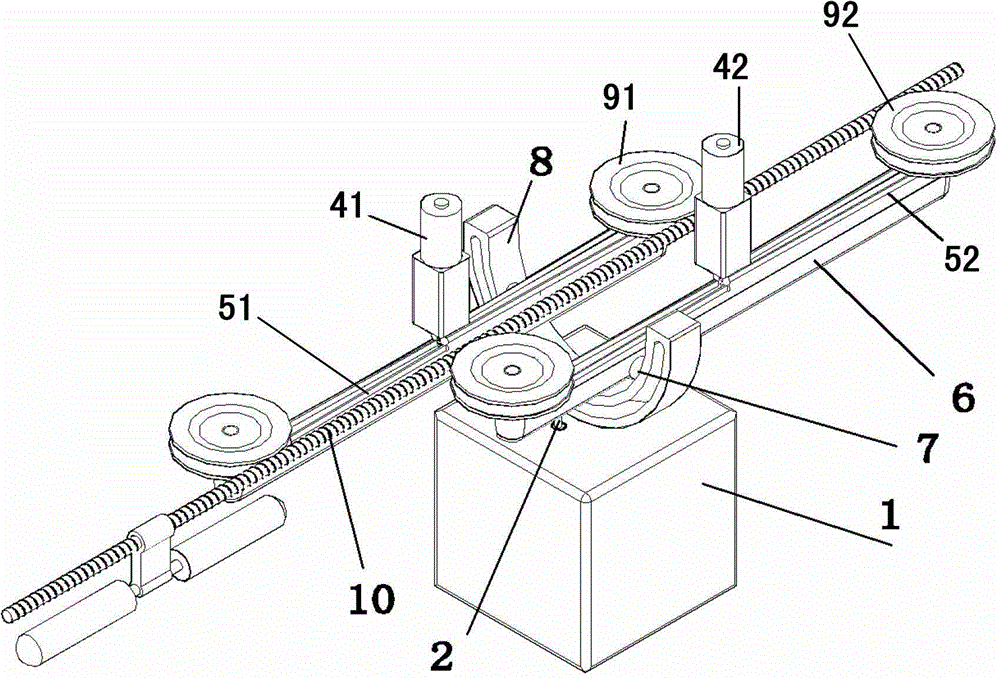

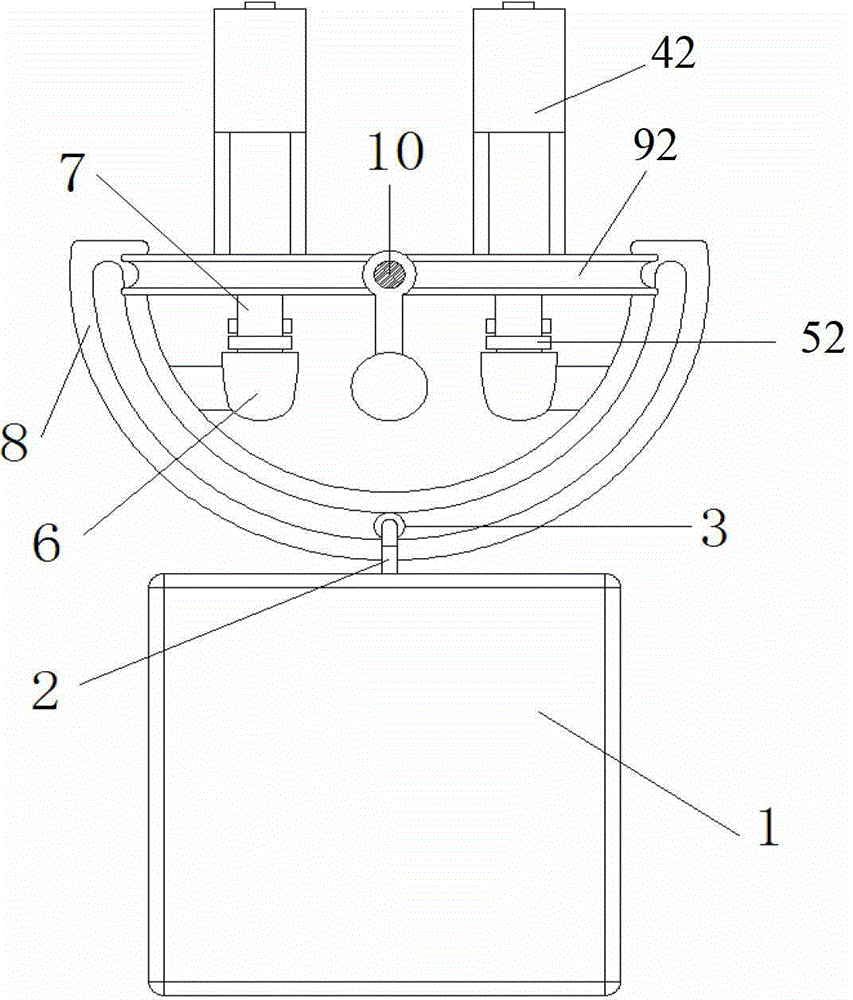

[0042] The obstacle-surmounting walking device of the line patrol robot of the present invention will be further elaborated below in conjunction with the accompanying drawings.

[0043] see Figure 1~6 , the embodiment of the present invention is provided with hanging bin 1, boom 2, gear 3, upper DC decelerating motor 41, lower DC decelerating motor 42, upper belt 51, lower belt 52, walking wheel arm 6, compression spring 7, U-shaped Support 8, upper traveling wheel 91, lower traveling wheel 92; said hanging storehouse 1 is equipped with a detection device and a U-shaped bracket rotation servo system, and the U-shaped bracket rotation servo system passes through the boom 2 and the gear located in the middle of the boom 2 3 connection, through the rotation of the driving gear 3 to realize the ±90 degree rotation of the U-shaped bracket 8; the U-shaped bracket 8 is connected to the walking wheel arm 6 through the compression spring 7; the walking wheel arm 6 is provided with a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com