High voltage dynamic reactive compensation device

A compensation device and dynamic technology, applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve equipment process structure, cost, efficiency problems, volume, cost, power semiconductor devices, efficiency limitations, etc. Problems, Achieve the effects of improving production efficiency, increasing compensation performance, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

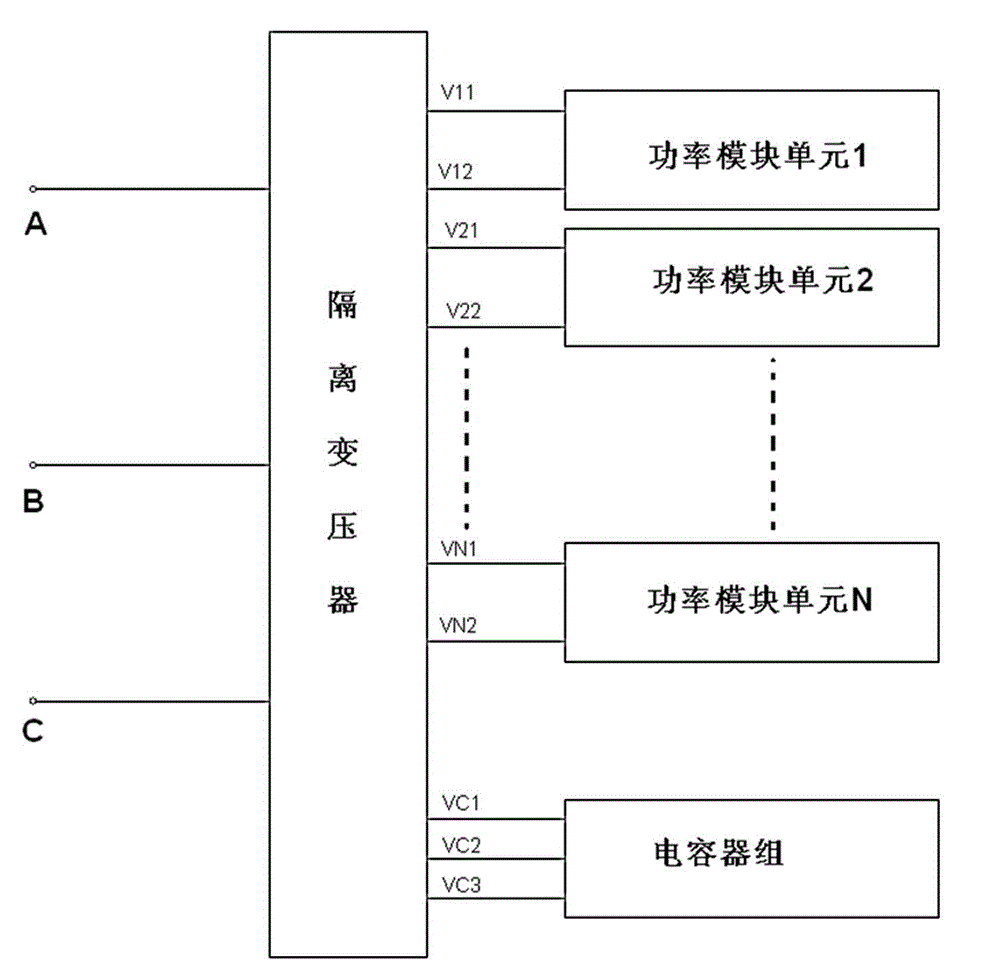

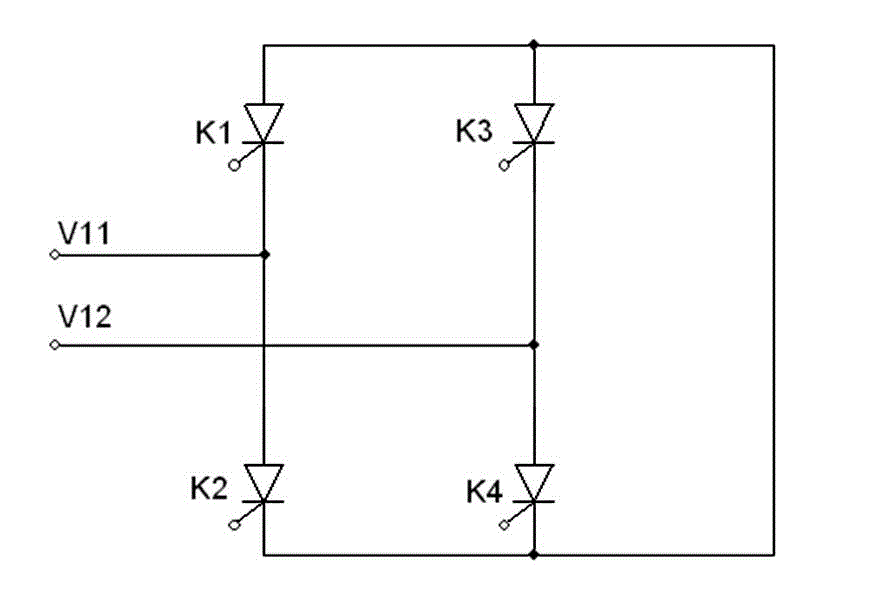

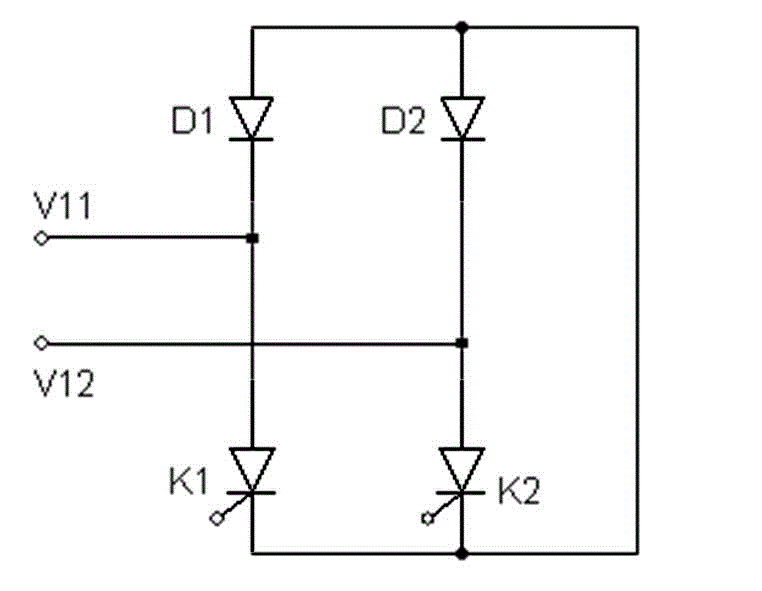

[0023] Such as figure 1 As shown, the system circuit block diagram of the reactive power compensation device of the present invention is given, which includes an isolation transformer, a three-phase capacitor bank, and 3n power module units, where n is a positive integer; Figure 8 It is the circuit diagram of the transformer. The primary side of the transformer shown is a three-phase winding, which is used to connect to the power grid; the secondary side is 3n single-phase windings and a three-phase winding, and the 3n single-phase windings are respectively connected to 3n power modules. The units are connected in phase, and the three-phase winding on the secondary side is used to connect with the three-phase capacitor. The input V11, V12, V21, V22, ... VN1 of the power module unit is connected to the secondary single-phase winding V11, V12, V21, V22,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com