Method for producing high-strength components by means of adiabatic blanking

A technology for parts and workpieces, applied in the field of producing high-strength parts by adiabatic stamping, to achieve the effects of simple production, high efficiency and easy flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

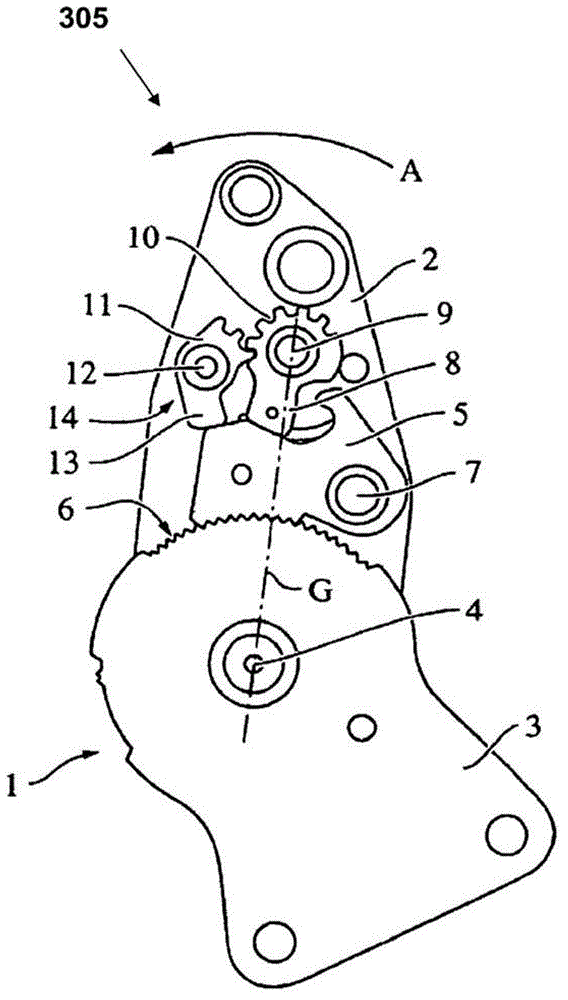

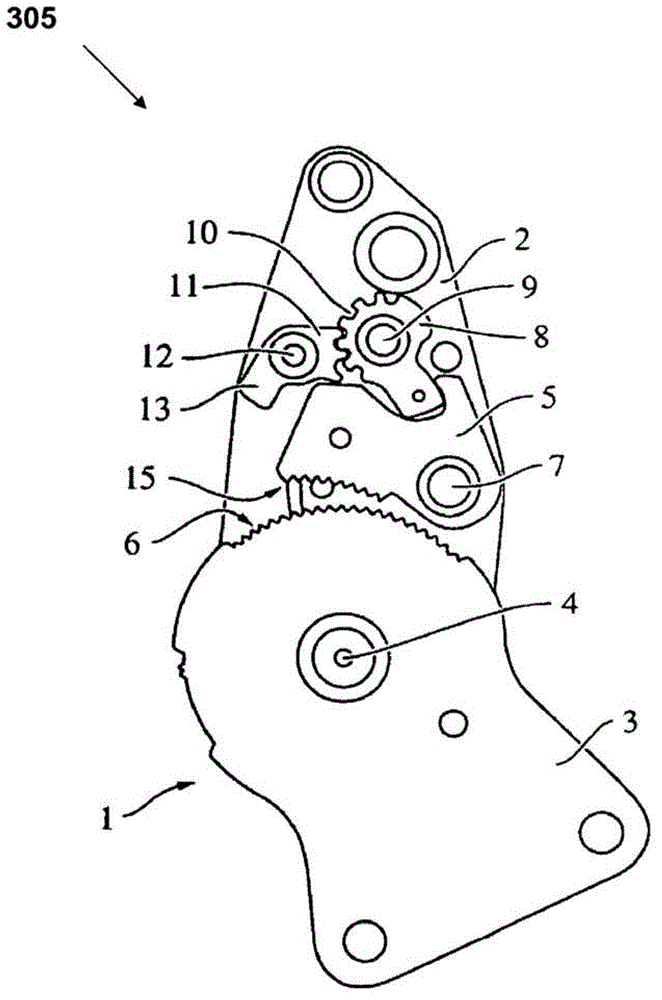

[0020] figure 1 A blocking and tilt adjustment device with a latching pawl according to the invention is shown schematically. The fitting 1 consists of a first fitting part 2 and a second fitting part 3 which are rotatable with respect to each other about a rotation axis 4 . The second fitting part 3 is for example arranged on the seat part and the fitting part 2 is arranged on the backrest of the vehicle seat, or vice versa. The locking takes place by engaging the mating teeth 15 of the latching pawl 5 into the teeth 6 of the second fitting part 3 . The latching pawl 5 is arranged on the fitting part 2 so as to be rotatable about the axis 7 and is clamped in the tooth 6 by the blocking cam 8 and fixed in this position. The blocking cam 8 , which rests on the periphery of the latching pawl 5 , rotates relative to the fitting part 2 about the axis of rotation 9 and meshes with a pinion 11 , via partial peripheral teeth 10 , which has a direction along the latching pawl 5 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com