Roof structure, fixture for solar cell module, and method for installing solar cell module

A technology for solar cells and installation tools, which is applied to the support structure of photovoltaic modules, photovoltaic modules, building structures, etc., and can solve problems such as cracks, lack of tiles, and screws that cannot function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0162] Embodiments of the present invention will be further described below.

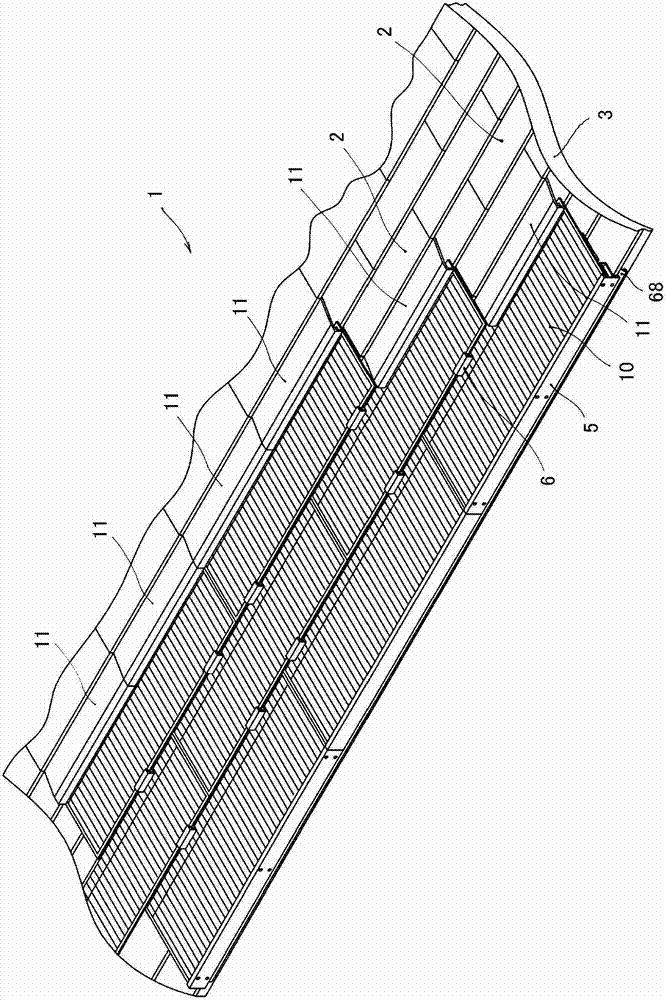

[0163] Such as figure 1 As shown, the roof structure 1 of this embodiment is formed on a basic roof structure 3 paved with slate tiles (roof components) 2 via an eaves end mounting part (eaves end mounting tool) 5 and an intermediate mounting part (installation tool) 6 The structure in which the solar cell module 10 is mounted. Moreover, the flashing 11 is partially provided in the necessary part.

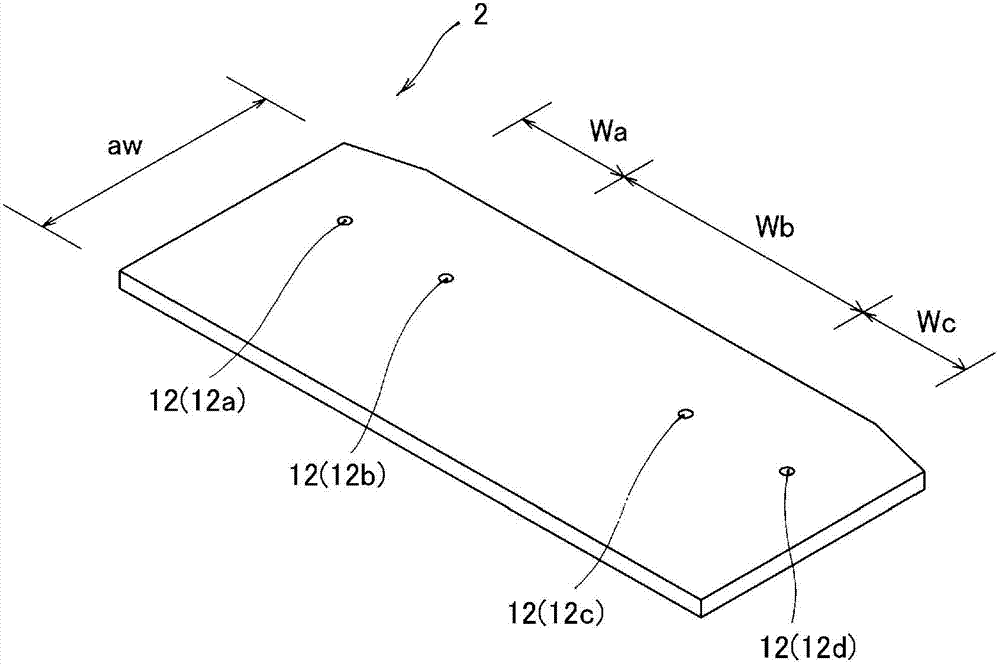

[0164] Such as figure 2 As shown, the slate tile 2 is an approximately rectangular thin plate formed from cement or the like. Near the center of the slate tile 2 in the short side direction, four mounting holes 12 are provided in advance in one row. In the present embodiment, the intervals between the attachment holes 12 are uneven, and the intervals between the two central holes 12b and 12c are larger than the intervals between the other holes.

[0165] In detail, if the four holes are hole 12a, h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com