Surface treating device of mirror

A surface treatment device and surface treatment technology, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of mirror damage, mirror crack, chromium layer peeling, etc., to reduce the number of parts and prevent cracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, embodiments of the present invention will be described based on embodiments of the present invention shown in the drawings.

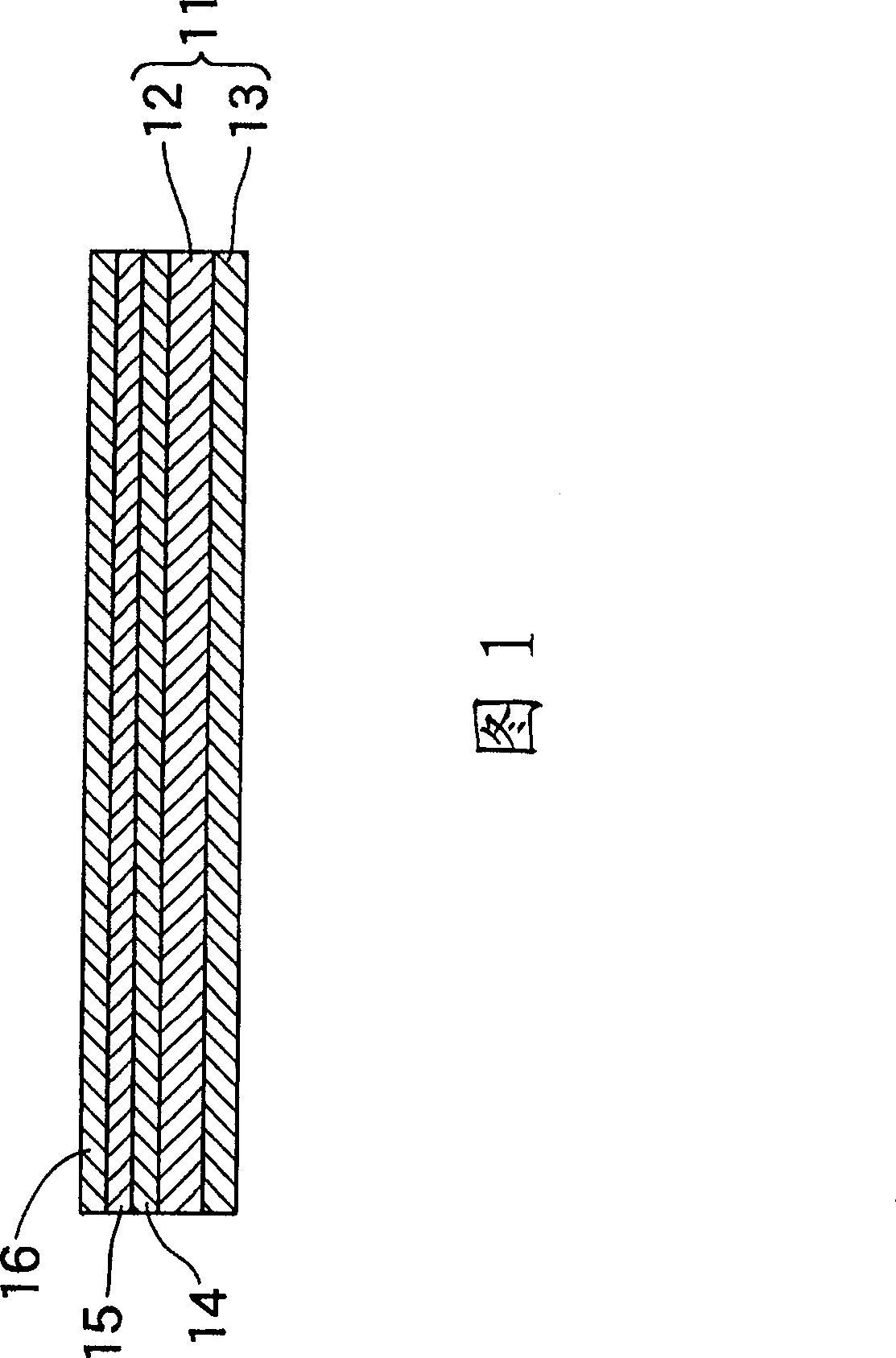

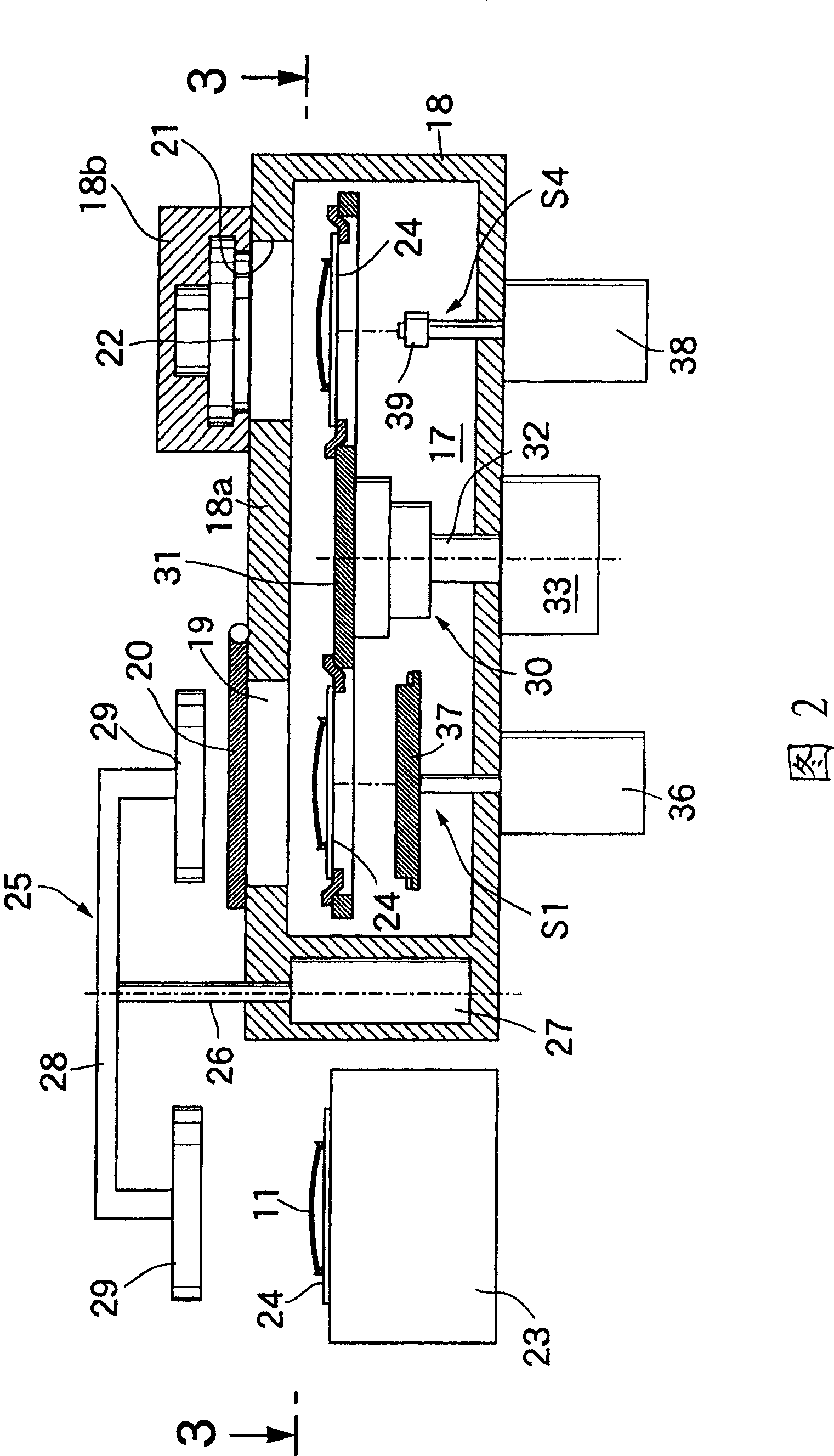

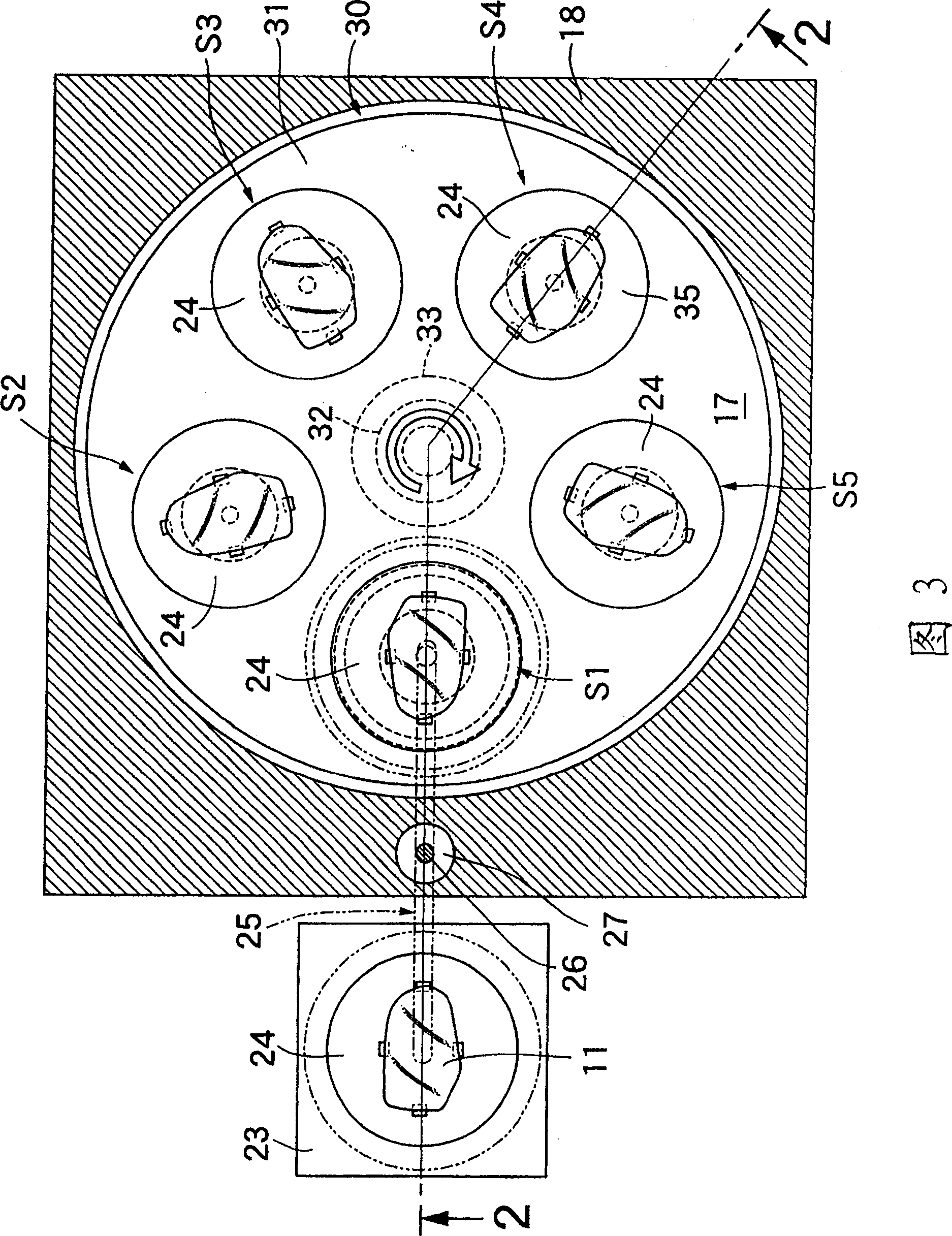

[0025] Figure 1~ Figure 6 Represent the first embodiment of the present invention, Fig. 1 is the longitudinal sectional view of the mirror after the surface treatment, Fig. 2 is the longitudinal sectional view of the surface treatment device, is the sectional view along the 2-2 line of Fig. 3, Fig. 3 is along the The sectional view of 3-3 line of Fig. 2, Fig. 4 is the sectional view corresponding to Fig. 2 when carrying out surface treatment state, Figure 5 It is a top view of the tray when the mirror is placed, Figure 6 is along Figure 5 Sectional drawing of line 6-6.

[0026] First, in FIG. 1 , the mirror 11 is, for example, a mirror used as a door reflector for a vehicle, and a chrome layer 13 is formed on the back of the glass plate 12 by vapor deposition. Implement surface treatment so as to overlap in order: by SiO 2 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com