Base plate structure for baking oven with upper heat source

A technology of placing a heat source on top of an oven, applied in the field of ovens, can solve the problems of excessive food grilling, cumbersome operation, and difficulty in accurate control, and achieve the effects of avoiding heat loss, low heat loss rate, and small supporting area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

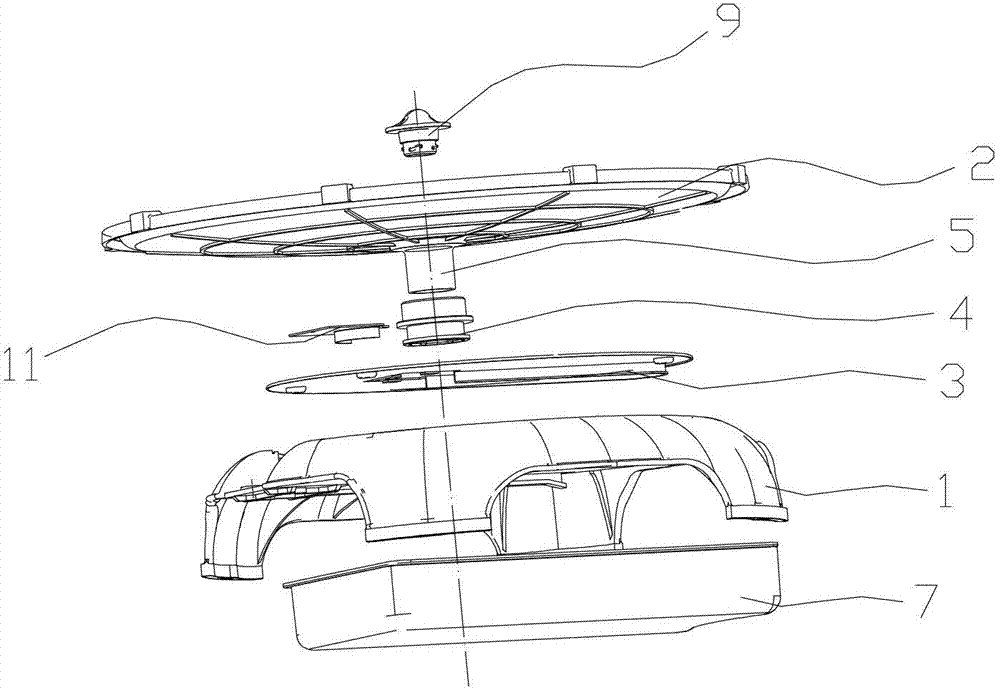

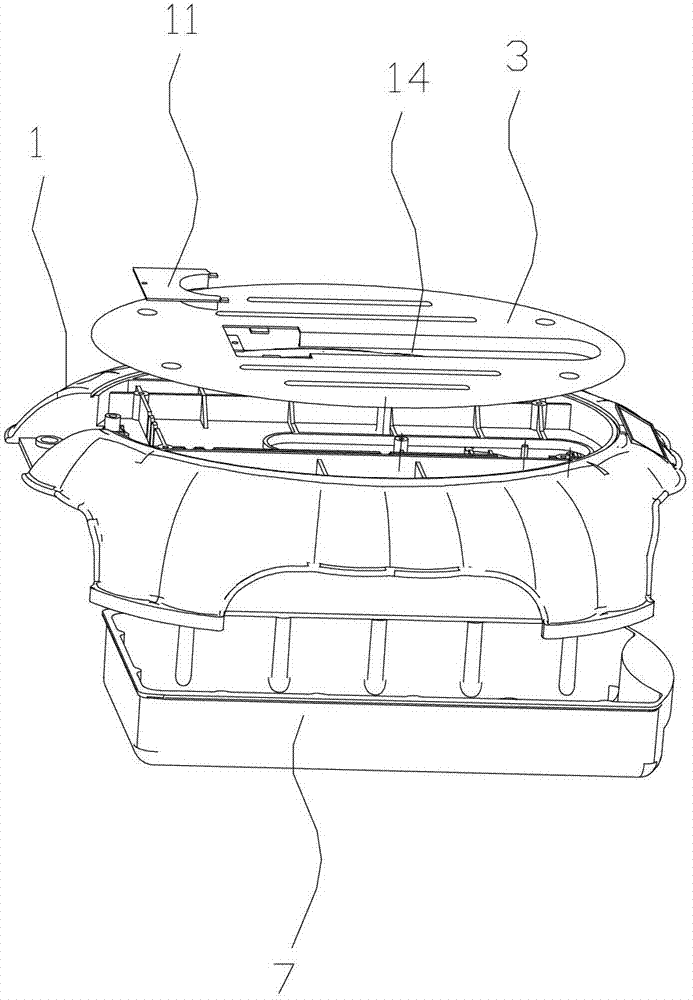

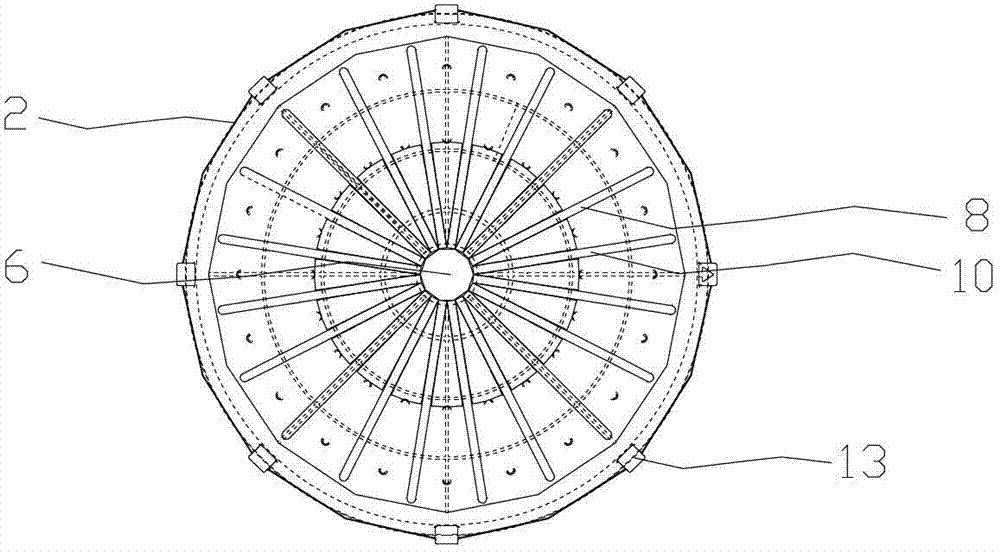

[0022] The present invention will be further described below with reference to the accompanying drawings.

[0023] Such as Figure 1-Figure 6 As shown, the chassis structure of a heat source top-mounted oven described in this embodiment includes a base 1 and a baking pan 2. The base 1 is made of plastic material and a metal plate 3 is arranged in the middle. The metal plate 3 A long hole 14 is opened on the metal plate 3 and a metal support 4 that can slide in the long hole 14 is provided on the metal plate 3 , and the baking pan 2 is supported on the metal support 4 . The metal plate 3 is provided with a plurality of parallel reinforcing ribs to improve the strength.

[0024] A positioning protrusion 5 is provided in the middle of the bottom surface of the baking pan 2 , and the positioning protrusion 5 is embedded in a hollow metal support 4 , and the metal support 4 is higher than the metal plate 3 . The hollow part of the metal support 4 passes through the base 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com