Heat treatment tooling for large thin-walled rotary steel castings and its application method

A technology of revolving body and steel castings, which is applied in the field of heat treatment tooling for large-scale thin-walled revolving body steel castings, can solve the problems of affecting the machining performance, increasing the cost of castings, oxygen cutting scars, etc. Effect of preventing deformation by heat treatment, reducing size and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

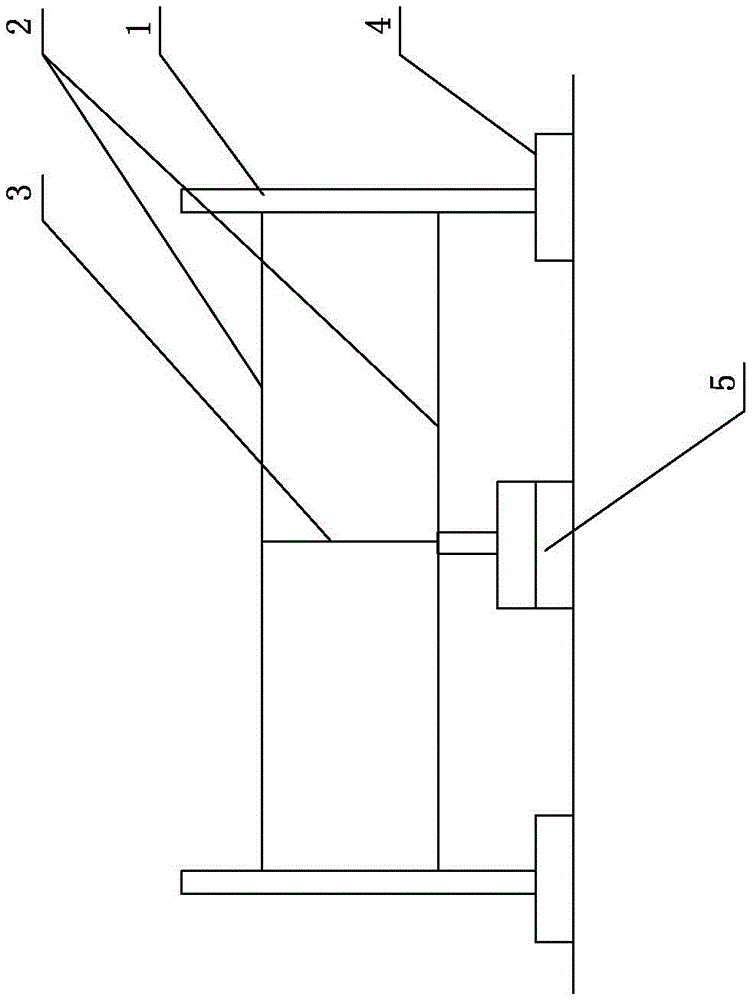

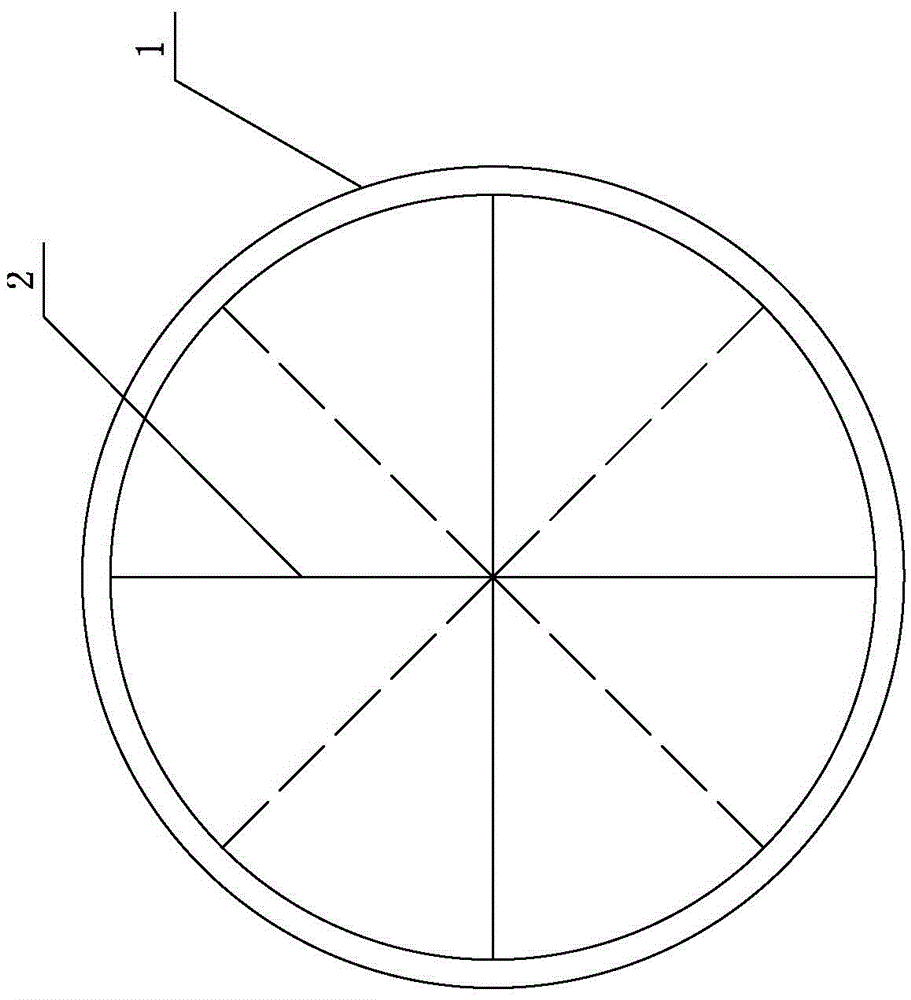

[0022] Such as figure 1 with figure 2 Shown is the heat treatment tooling for large thin-walled revolving body steel castings of the present invention, including two or more layers of radial tie bars 2 arranged in the revolving body 1 for supporting the inner wall of the revolving body 1, each layer of each The radial tie bars 2 intersect and are fixed at the center of rotation of the rotary body 1. A vertical support rod 3 is provided between the intersection points of the adjacent upper and lower radial tie bars 2 and below the intersection point of the lowest layer of radial tie bars 2. The tie bars 2 and the inner wall of the revolving body 1 are fixed by spot welding, and the radial tie bars 2 are welded and fixed at the intersection of the center of the revolving body 1 .

[0023] In order to further realize the balanced support of the rotary body casting up and down and in the radial direction, the radial tie bars 2 of the upper and lower adjacent layers are arranged ...

Embodiment 2

[0030] Adopt the above-mentioned large-scale thin-walled revolving body class steel casting heat treatment frock to prevent the using method of casting heat treatment deformation, the large-scale thin-walled steel casting in this method has a diameter of 4 meters, a height of 1 meter, and the wall thickness of the revolving body is 40mm. The heat treatment of the technical method has a large amount of deformation and a large amount of work in the later stage of plastic treatment. The method of the present invention is used to set the supporting tooling inside the rotary body through the following steps before heat treatment:

[0031] 1) In this embodiment, the radial ties 1 are arranged in upper and lower layers, the angle between the adjacent radial ties in each layer is 90°, and the radial ties in the upper and lower layers are staggered at 45°, and the diameter of the upper and lower layers The vertical distance to the tendons is 0.4 meters, and the distance between the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com