Two-sided material separation device

A material and sorting box technology, which is applied in classification, solid separation, chemical instruments and methods, etc., can solve the problems of difficulty in designing and manufacturing width machines, increasing operation difficulty, etc., and achieves compact structure, convenient operation, and reduced land occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

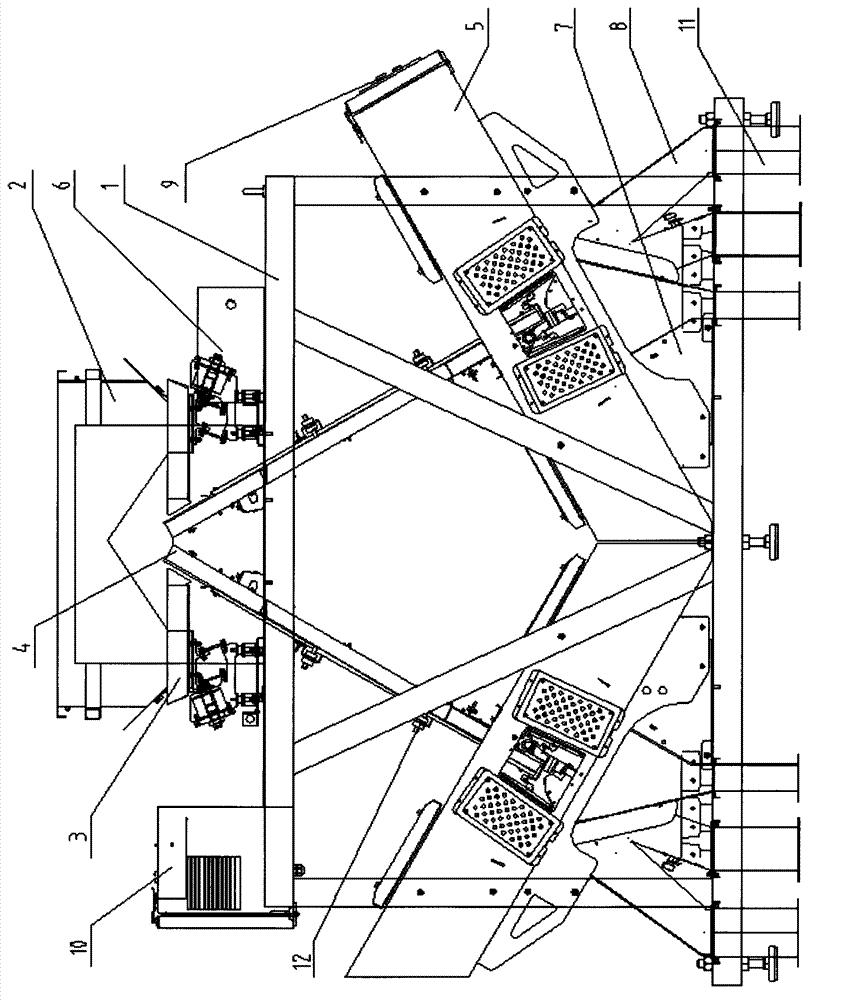

[0010] figure 1 It is a double-sided material sorting equipment, including frame 1, input hopper assembly 2, vibrator assembly 3, trough assembly 4, sorting box assembly 5, circuit breaker 6, valve seat box assembly 7, and output hopper assembly 8 , Hopper assembly 11 , cover cover assembly 12 , operation panel 9 , electric control box assembly 10 .

[0011] Two sets of material sorting systems are installed on the frame 1, namely the first set of material sorting system and the second set of material sorting system. The first set of material sorting system includes 1 vibrator assembly, 1 trough assembly, 1 sorting box assembly, 1 discharge hopper assembly, 1 valve seat box assembly, 1 socket hopper assembly, 1 cover skin Cover assembly. Similarly, the second set of material sorting system also includes 1 vibrator assembly, 1 trough assembly, 1 sorting box assembly, 1 discharge hopper assembly, 1 valve seat box assembly, 1 socket hopper assembly, 1 cover cover assembly. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com