Technology for extracting tellurium product and valuable metal from lead anode slime

A lead anode slime and valuable metal technology, applied in the field of lead anode slime treatment, achieves the effects of good separation effect, reduced production cost and process saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

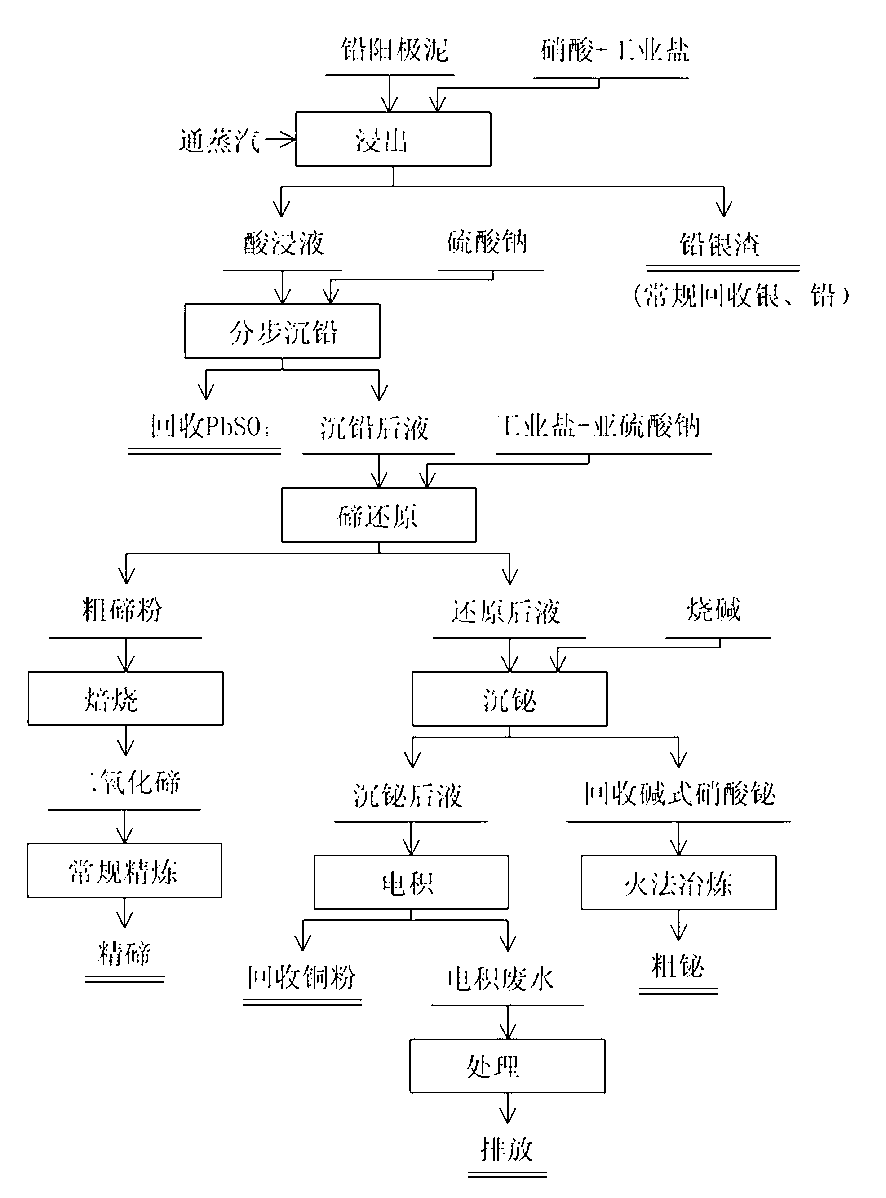

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] The composition of the lead anode slime used in the present embodiment is as follows:

[0025] Pb28.22%, Cu19.21%, Te7.03%, Bi25.91%, Ag4.45%;

[0026] The process steps for extracting tellurium products and valuable metals from the above-mentioned lead anode slime are as follows figure 1 .

[0027] The specific process and process parameters are as follows:

[0028] a. Oxidation leaching

[0029] Import the lead anode slime from the lead electrolytic cell into the reaction kettle; use nitric acid to process industrial salt for oxidative leaching, pass steam, control the liquid-solid ratio to 6-8:1 l / g, the concentration of nitric acid is 2.5M, and the industrial salt is 15 ~20 g / l; leaching temperature is 90°C, leaching time is 4-6 hours; stirring, so that valuable copper, bismuth, tellurium and most of the metal lead ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com