Novel airtight full-loaded four-row cylindrical roller bearing

A technology of cylindrical roller bearings and cylindrical rollers, applied to roller bearings, shafts and bearings, bearing components, etc., can solve the problems of small number of rollers, low bearing capacity, and difficulty in ensuring the accuracy of complete sets of bearings, etc., to achieve The effect of reducing the cost of use and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

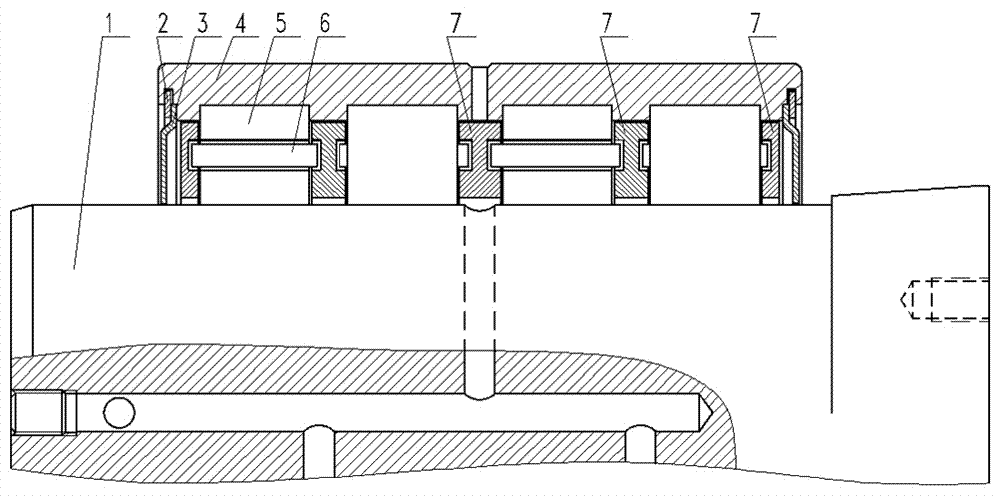

[0011] Such as figure 1 As shown, the present invention is a new type of sealed full complement four-row cylindrical roller bearing, including an outer ring 4, a pin shaft 1 serving as an inner ring, and four-row cylindrical rollers 5 installed between the two, wherein each There are cylindrical pillar holes on the axis of cylindrical rollers 5, support rings 7 are installed on both sides of each row of cylindrical rollers 5, and cylindrical pillars are inserted in the pillar holes of each cylindrical roller 5. 6, and there is a clearance fit between the pillar 6 and the pillar hole, and the two ends of the pillar 6 are installed in the pillar grooves on the support ring 7 respectively.

[0012] Wherein, a dust cover 3 is also installed between the outer ring 4 and the pin shaft 1 , and a spring ring 2 is also installed between the dust cover 3 and the outer ring 4 .

[0013] In order to realize the characteristics of high load, easy installation and replacement, and good eco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com