Electric lamp with an outer bulb and a built-in lamp and associated production method

A technology of electric lamps and external power supply, applied in discharge lamps, circuits, incandescent lamps, etc., can solve problems such as complex mechanical processes, and achieve the effect of improving efficiency and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

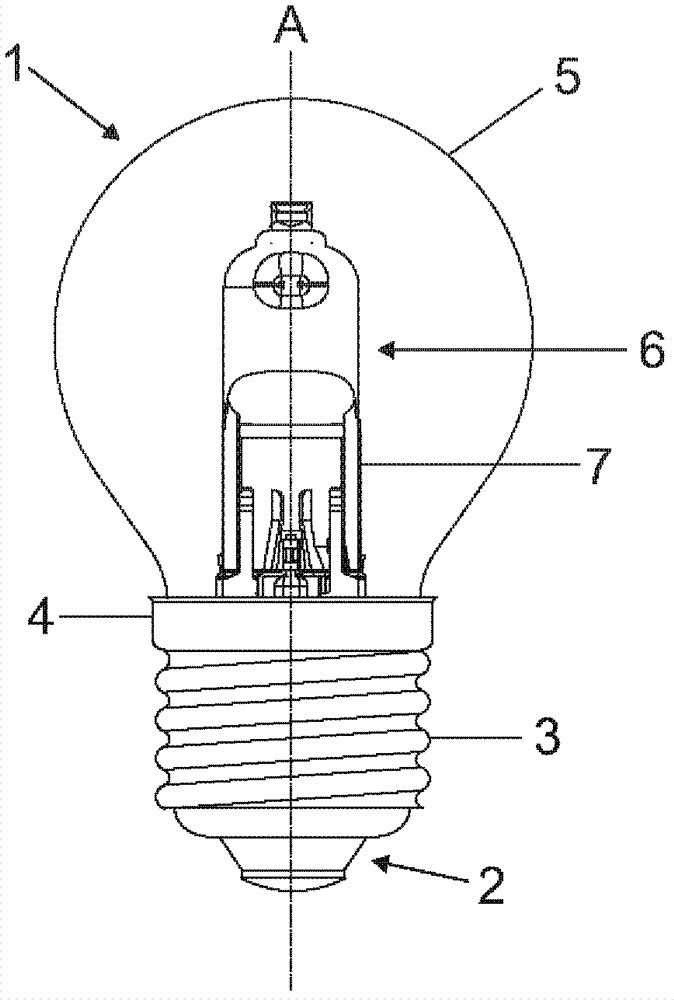

[0073] figure 1 A complete halogen incandescent lamp 1 is illustrated. In the base 2 of the conventional type E14 or E27, especially the base 2 with the base insulator or lamp mount of ceramics and the screw part 3 fastened thereto, and the base sleeve 4, the outer shell is bonded by means of a bonding agent. The bulb 5 is held in the base sleeve 4 . The built-in lamp 6 is arranged inside the outer bulb 5 . The built-in lamp 6 is in the form of a so-called high-voltage halogen incandescent lamp and is known per se from the prior art. The lamp 1 has a longitudinal axis A, on which the built-in lamp is also arranged.

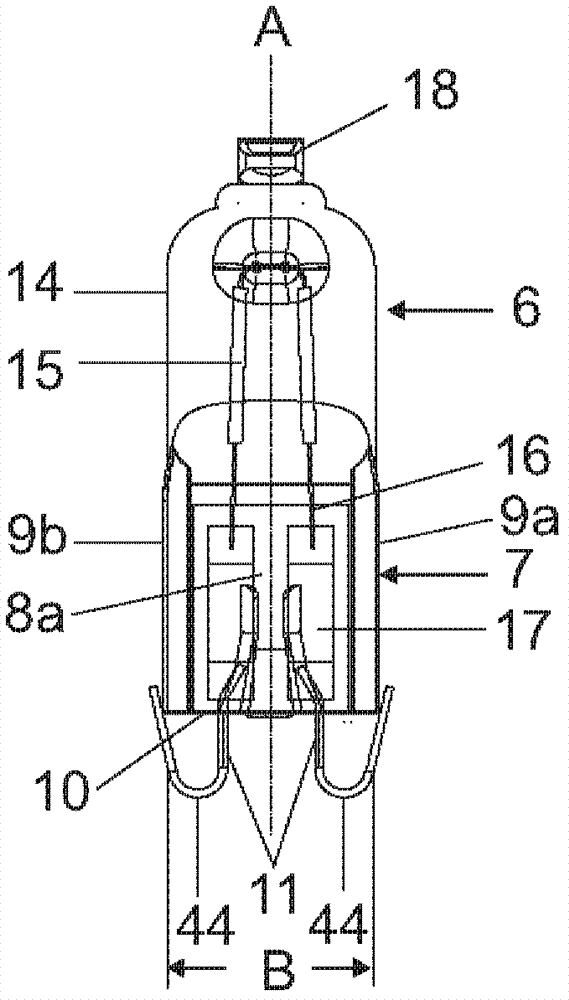

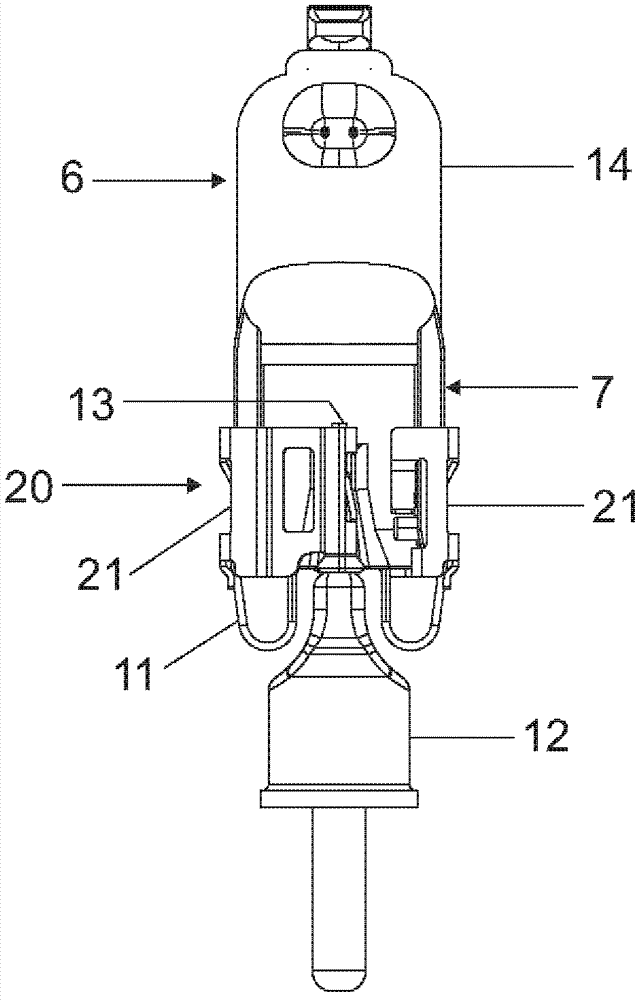

[0074] Built-in lamp 6 (see also figure 2 ) is equipped with a single pinch seal 7 having two broad sides 8a and 8b, two narrow sides 9a and 9b and a bottom 10. A pin-shaped external power supply line 11 protrudes from the pinch seal 7 . Such as figure 2 As shown, these external supply lines 11 are bent back outwards in the direction of the narrow side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com