Heat-insulating panel for use in buildings

A heat insulation board and building technology, applied in the direction of building structure, building, building components, etc., can solve the problems of cost increase, time-consuming, low cost and high efficiency, etc., and achieve sufficient heat storage and high heat insulation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

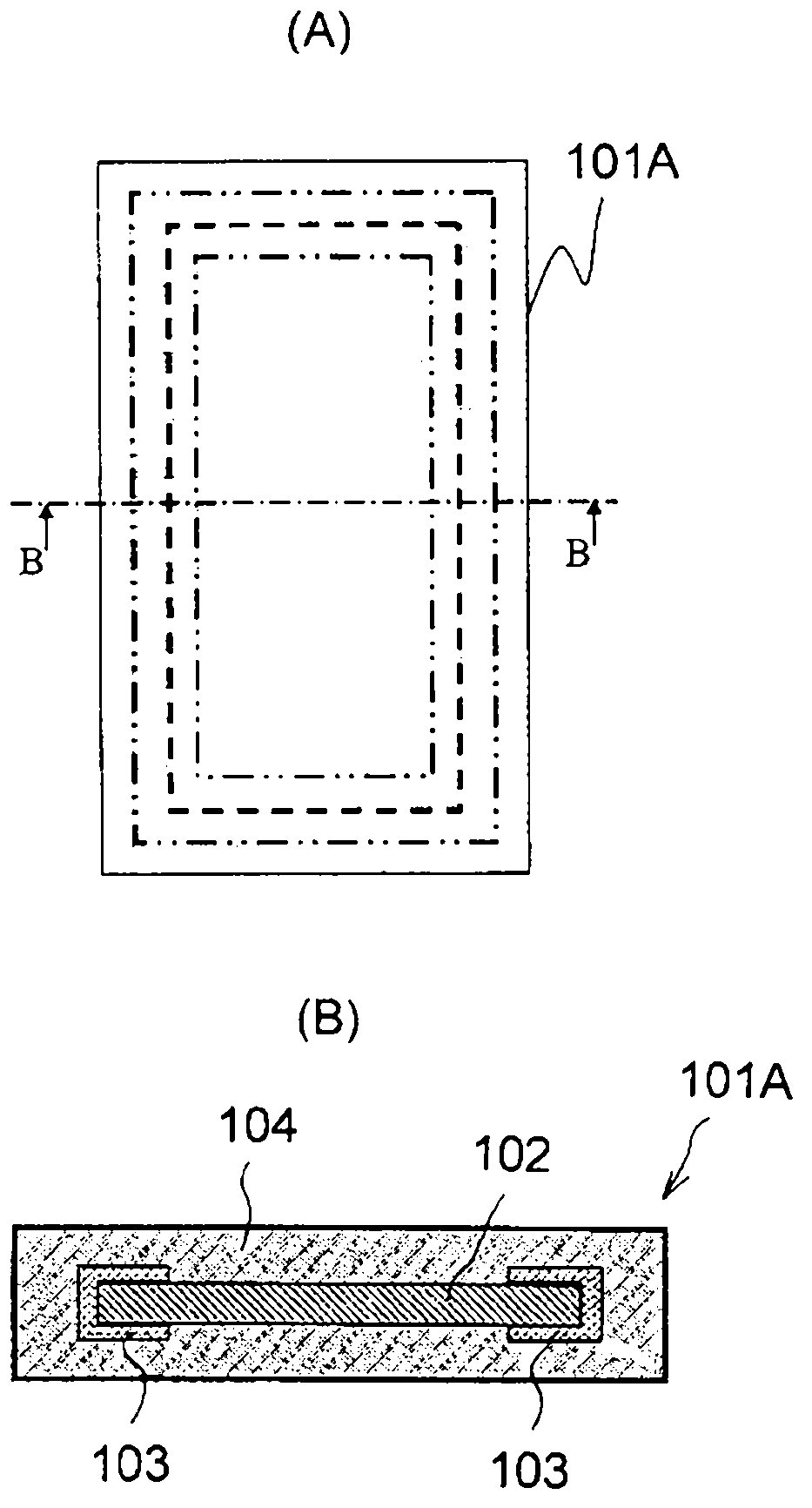

[0047] figure 1 It is a diagram showing a schematic configuration of a heat insulating panel 101A for a building according to Example 1 of the present invention, the diagram (A) is a plan view showing the interior partly seen through from above, and the diagram (B) is B-B of the diagram (A) A side sectional view in the width direction viewed along the line.

[0048] refer to figure 1 (A) and (B), the heat insulating panel 101A for a building has a basic structure in which the entire flat vacuum heat insulating material 102 is covered with the heat insulating material 104 , and the entire periphery of the vacuum heat insulating material 102 is covered with The method is equipped with a latent heat storage material 103 formed in a substantially frame-like shape connected from one main surface of the vacuum heat insulating material 102 to the other main surface over a side wall. The latent heat storage material 103 is provided for relieving thermal bridges caused by heat leakag...

Embodiment 2

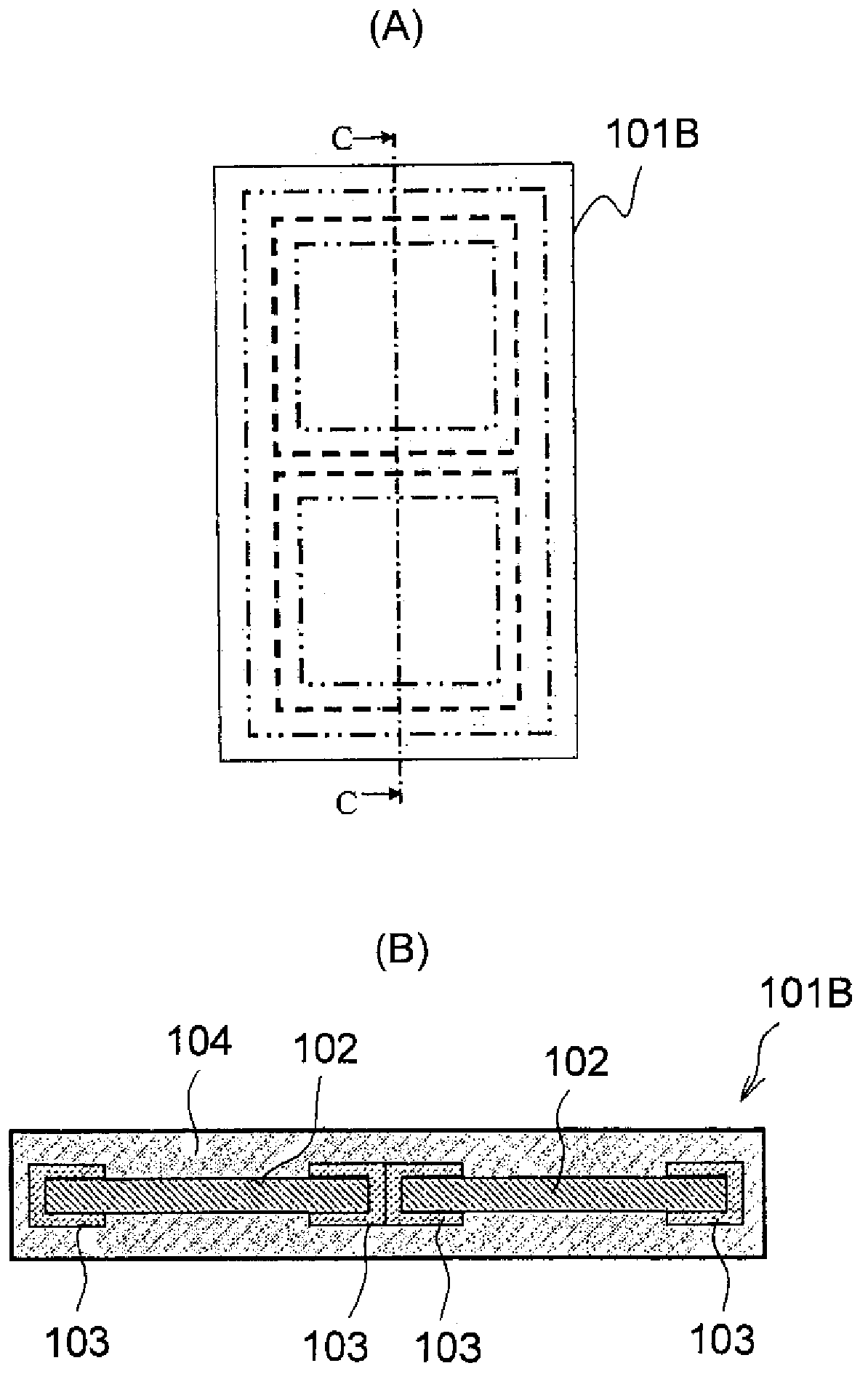

[0059] figure 2 It is a diagram showing a schematic configuration of a heat insulating panel 101B for a building according to Example 2 of the present invention, the diagram (A) is a top view showing the interior partly seen through from above, and the diagram (B) is C-C of the diagram (A) A side sectional view along the length of the line.

[0060] refer to figure 2 (A) and (B), the heat insulating panel 101B for a building is basically formed by covering the whole of a plurality (here, two) of flat vacuum heat insulating materials 102 arranged at predetermined intervals with a heat insulating material 104 . In addition to the structure, a plurality of (here, two) latent heat storage materials 103 are provided so as to cover the vicinity of the entire periphery of each vacuum heat insulating material 102, and the latent heat storage materials 103 form one main surface of each vacuum heat insulating material 102. A substantially frame-like shape connected to the other side...

Embodiment 3

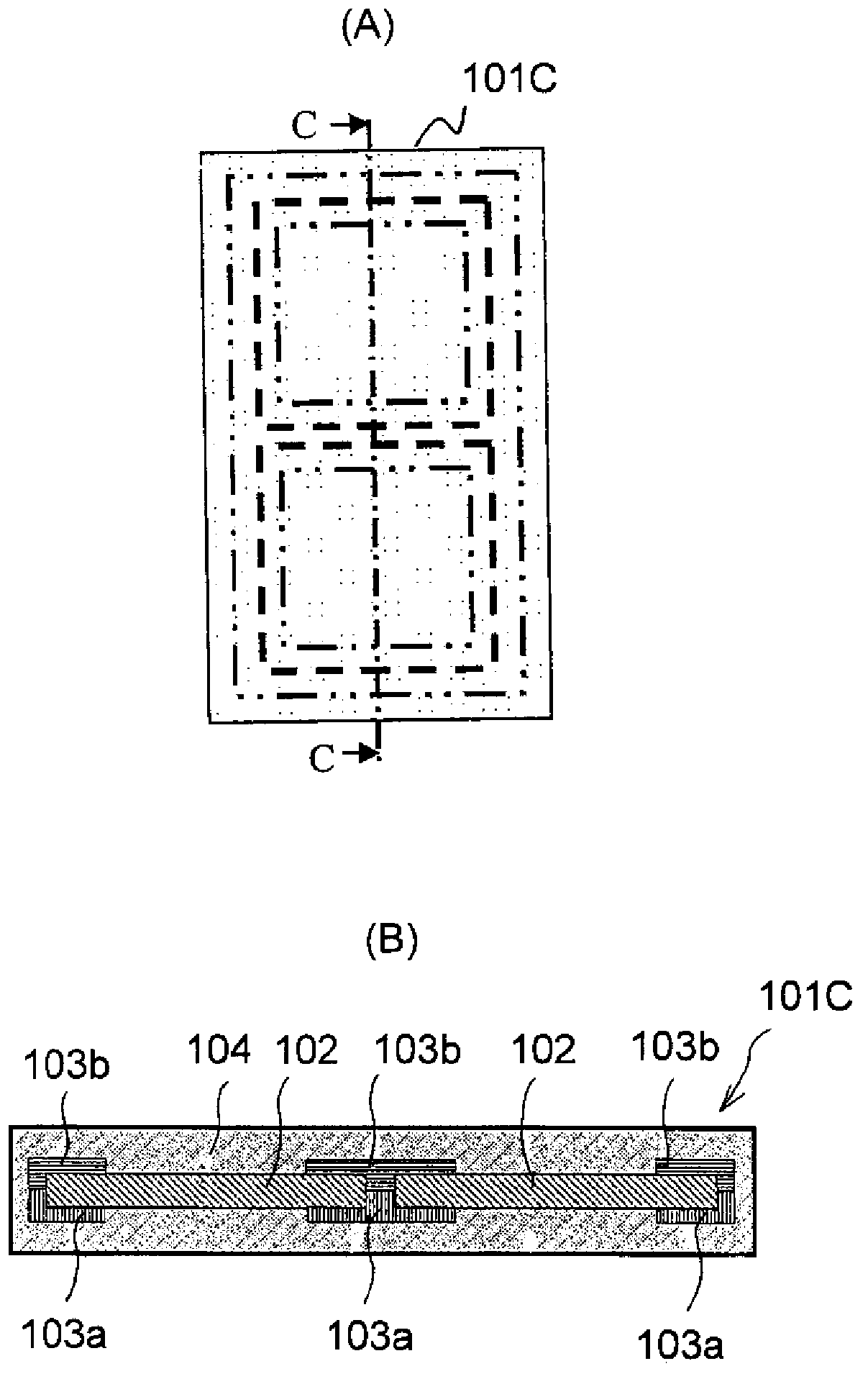

[0066] image 3 It is a diagram showing a schematic configuration of a heat insulating panel 101C for a building according to Example 3 of the present invention, the diagram (A) is a plan view showing the interior partly seen through from above, and the diagram (B) is C-C of the diagram (A) A side sectional view along the length of the line.

[0067] refer to image 3(A) and (B), the heat insulating panel 101C for a building is basically formed by covering the whole of a plurality (here, two) of flat vacuum heat insulating materials 102 arranged at predetermined intervals with the heat insulating material 104 . In addition to the structure, the first latent heat storage material 103a and the second latent heat storage material 103b are equipped, and the first latent heat storage material 103a, the first latent heat storage material 103a is formed from each of the vacuum heat insulating materials 102 to one The main surface side is connected in a substantially lattice frame s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com