Ultralow-temperature liquefied gas pressure vessel and heat insulation method

A technology for liquefied gas and pressure vessels, applied in the field of pressure vessels, can solve the problems of affecting the adiabatic effect of ultra-low temperature liquefied gas pressure vessels, and cannot completely eliminate heat conduction, convection and radiation, etc. safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

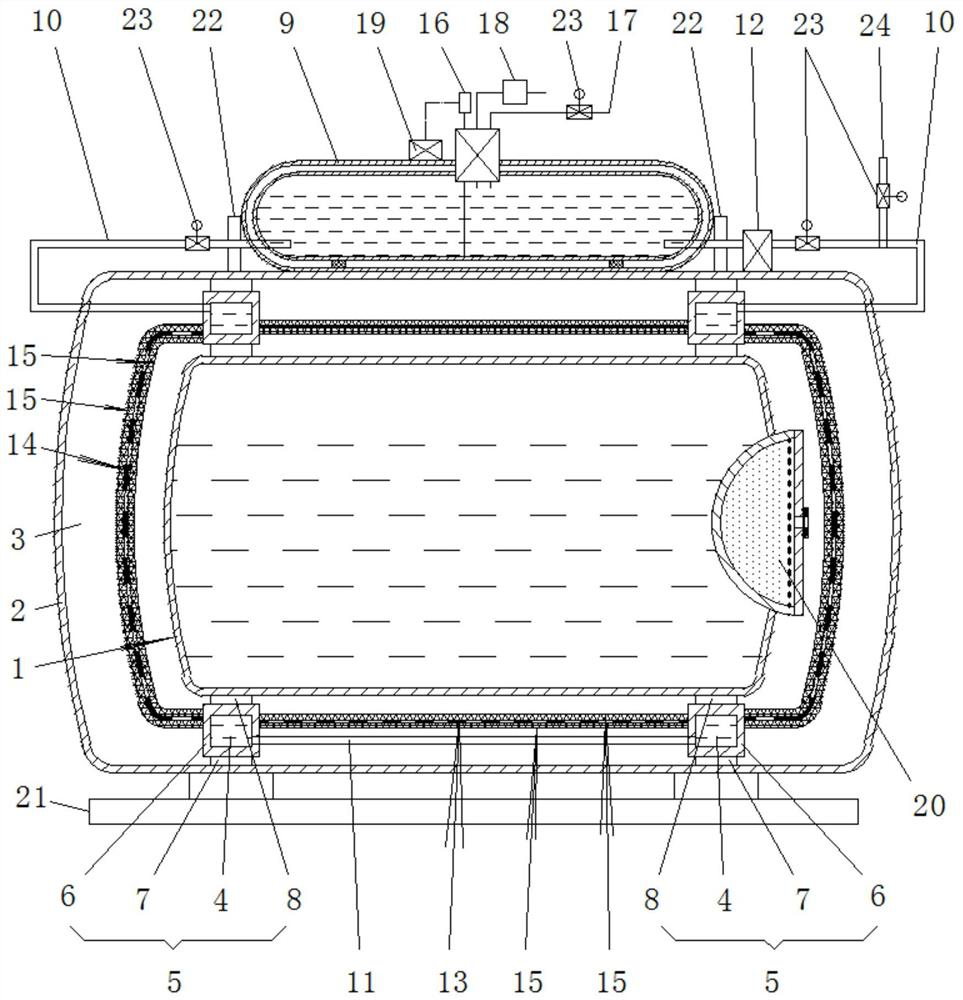

[0032] Such as figure 1Shown is an embodiment of an ultra-low temperature liquefied gas pressure vessel and the heat insulation method of the present invention, including an inner vessel 1, an outer vessel 2, a interlayer space 3 formed between the inner vessel 1 and the outer vessel 2, a support A support assembly between the inner container 1 and the outer container 2, the support assembly includes a pair of support rings 6 with an annular hollow cavity 4, arranged on the outer periphery of the support ring 6 and spaced along the circumferential direction A number of outer support heat insulation pads 7 arranged to support the inner wall of the outer con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com