Linear array type pyroelectric infrared detector with heat insulation structure

A pyroelectric infrared and detector technology, applied in electrical radiation detectors, instruments, measuring devices, etc., can solve the problems of limited application range, high cost, and complex device structure of refrigeration detectors, and achieve improved thermal performance and The effect of outputting signal current, improving electrical conductivity, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

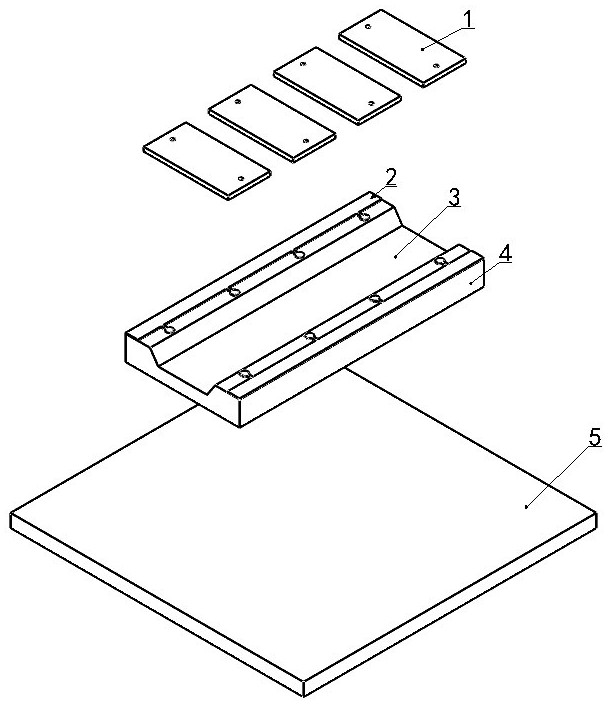

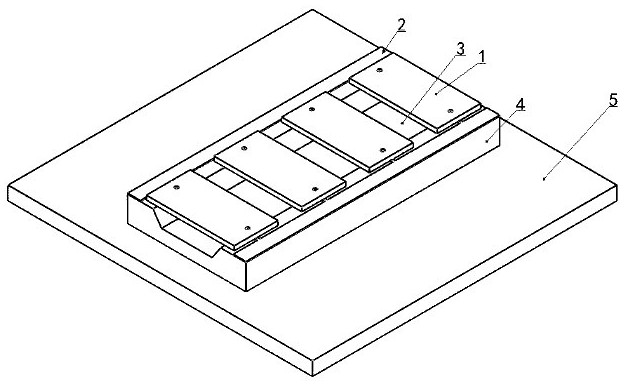

[0029] Such as figure 2 The pyroelectric infrared array device shown has excellent thermal and mechanical properties, and has a high specific detection rate. It can be used not only in military fields such as aerospace, but also in civilian fields such as security monitoring. It includes one or more An infrared photosensitive element 1, a heat insulation structure and a PCB board 5 carrying line devices.

[0030] Such as figure 2 The infrared array device shown is a 4-element array, and it only needs to lengthen the size of the ceramic insulation structure, and it can better carry 8-element array or 16-element array sensitive elements; the front and back surfaces of the infrared device have electrodes, for The shape of the upper electrode of the device is not restricted, but the upper electrode needs a contact hole capable of wire bonding, and the lower electrode needs to be able to contact the patterned metal electrode 2 on the heat insulation structure; the heat insulatio...

Embodiment 2

[0032] On the basis of Example 1, this example discloses an optimized process flow for the preparation of pyroelectric infrared sensor devices:

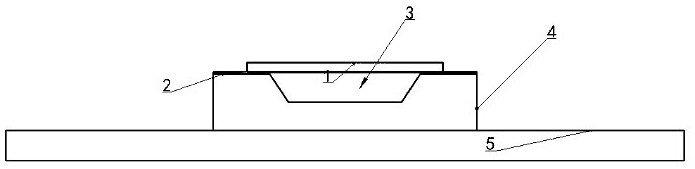

[0033] For the ceramic heat insulation structure, ceramics with a thickness of about 2 mm are selected for UV laser processing to etch a tunnel-shaped suspended structure with a depth of about 1 mm, such as image 3 As shown, the shape of the air gap 3 is trapezoidal, the length of the upper side is greater than the length of the lower side, and the length of the upper side is smaller than the width of the device. Then use a hard mask to vapor-deposit gold on the upper surface of the ceramic insulation structure to form a figure 1 the graph shown. Next, apply conductive silver glue to the circle on the patterned metal electrode 2, and align the prepared pyroelectric infrared device with upper and lower electrodes with the air gap 3 of the ceramic structure 4 and the circle of the patterned metal electrode 2. At the contact point, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com