Hydrodynamic torque converter

一种液力变矩器、变矩器的技术,应用在弹簧/减震器、流体传动装置、振动抑制调整等方向,能够解决扭振阻尼器阻尼性能不令人满意等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

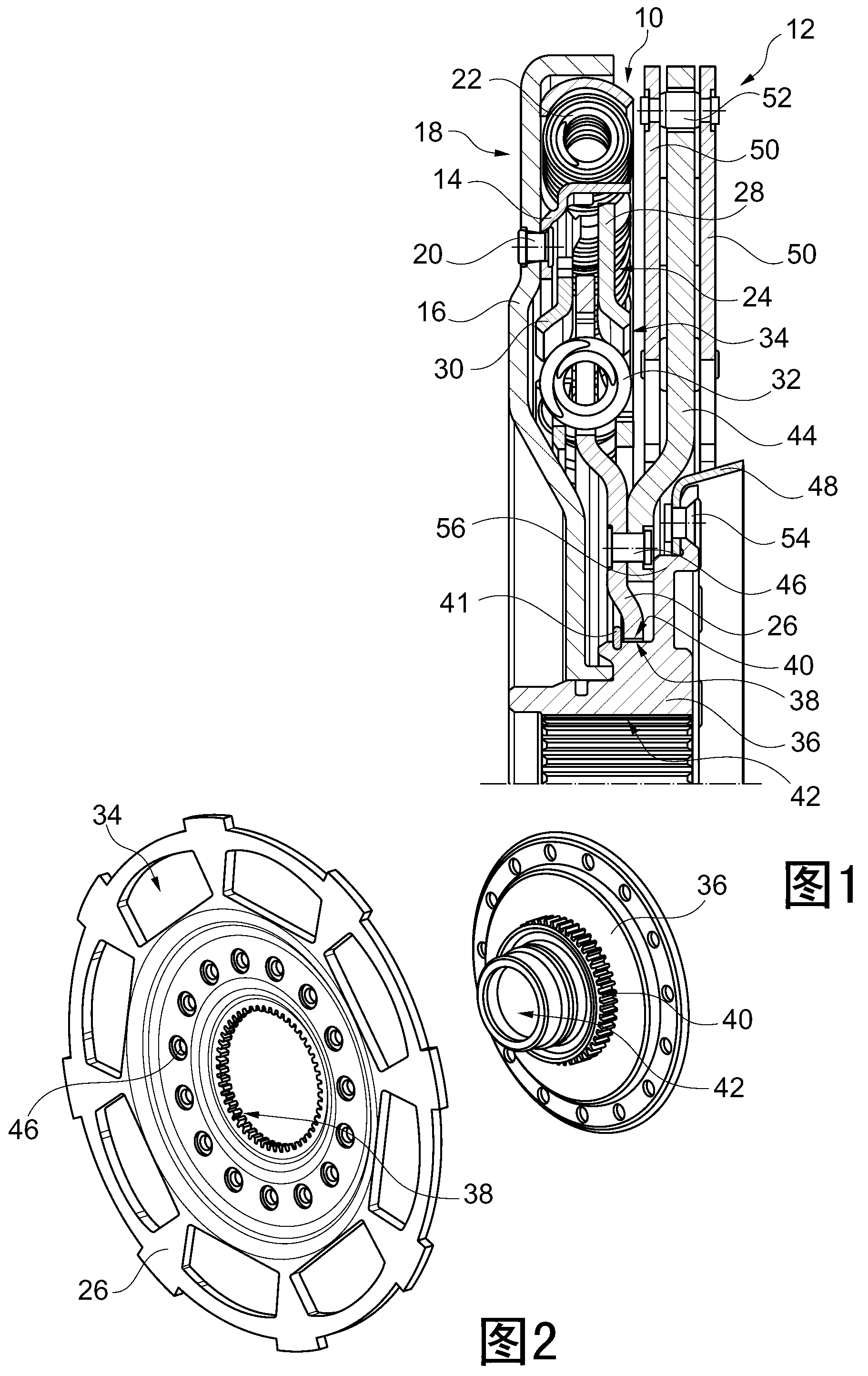

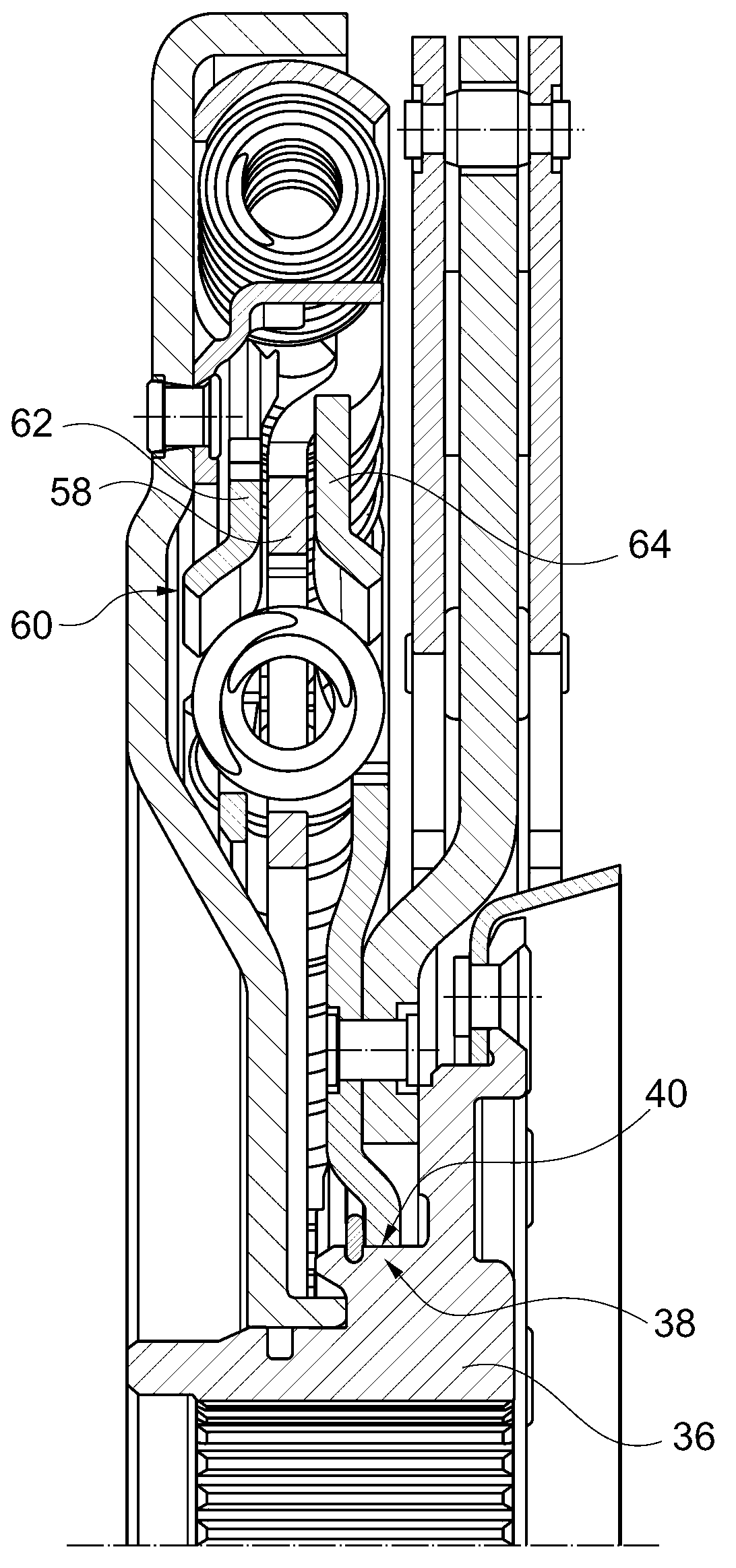

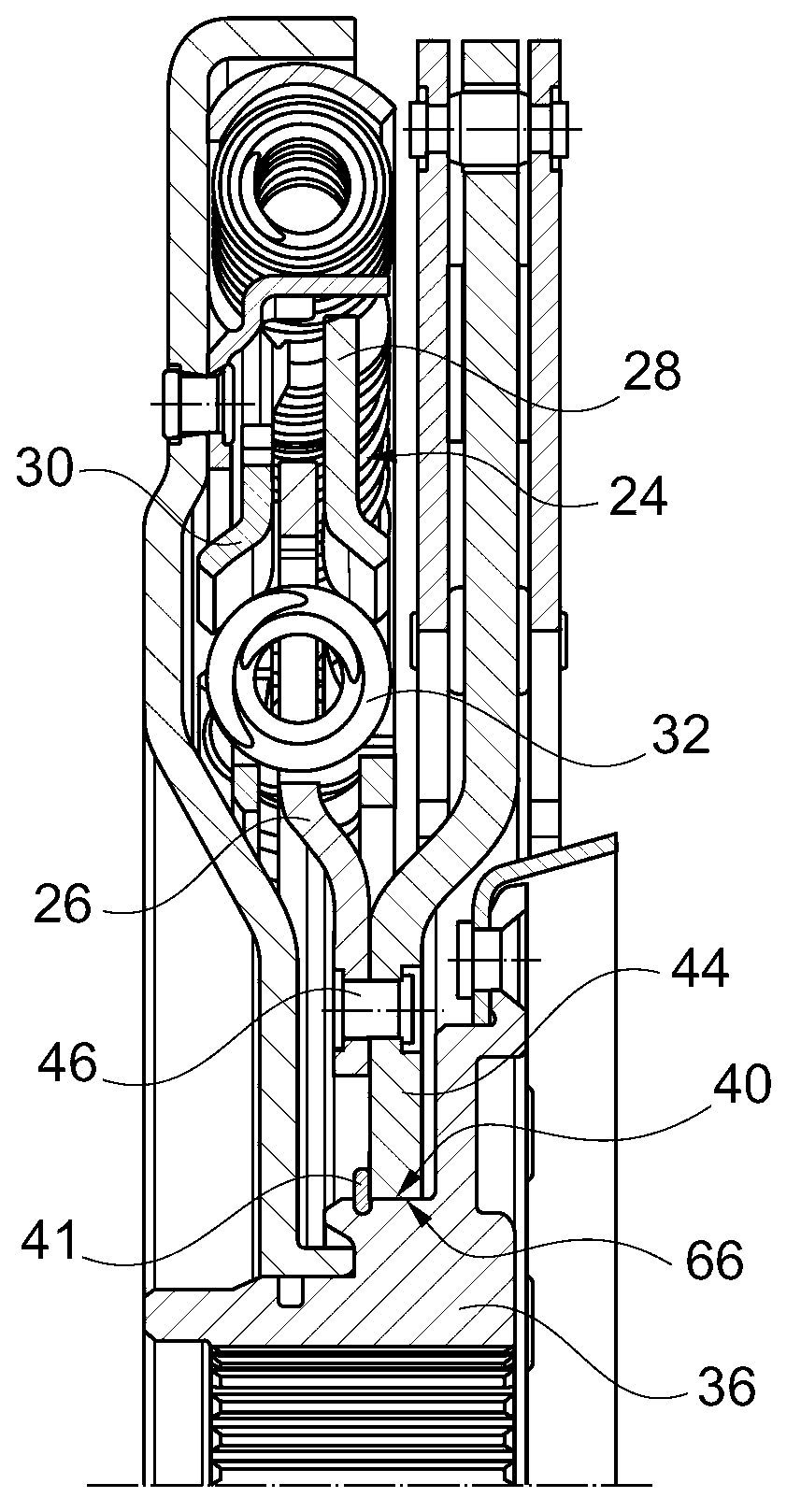

[0018] figure 1 shows a cross-sectional view of a torque converter according to an embodiment of the present invention, additionally figure 2 Shows damper output section and output hub in perspective view. The sectional illustration shows a torsional vibration damper 10 and a centrifugal pendulum device 12 arranged inside the torque converter housing and formed as a series damper. The damper output part 14 of the torsional vibration damper 10 is non-rotatably connected to the clutch output 16 of the torque converter bridge clutch 18 via a riveting element 20 . The damper input part 14 is now connected via a radially outer first energy storage element 22 to a damper middle part 24 , which is rotatable to a limited extent relative to the damper input part 14 . The damper middle part 24 surrounds the first energy storage element 22, such as a bow spring, to secure it radially and axially. The first energy storage element 22 applies a load to the first outer peripheral side th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com