Skin stapler with automatic staple releasing spring structure

A technology of suturing device and spring mechanism, which is applied in the field of medical devices, can solve the problems of poor needle shape, unstable function, and prone to needle pinching, etc., and achieve the effects of eliminating influence, reliable function realization, and eliminating pin pinching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

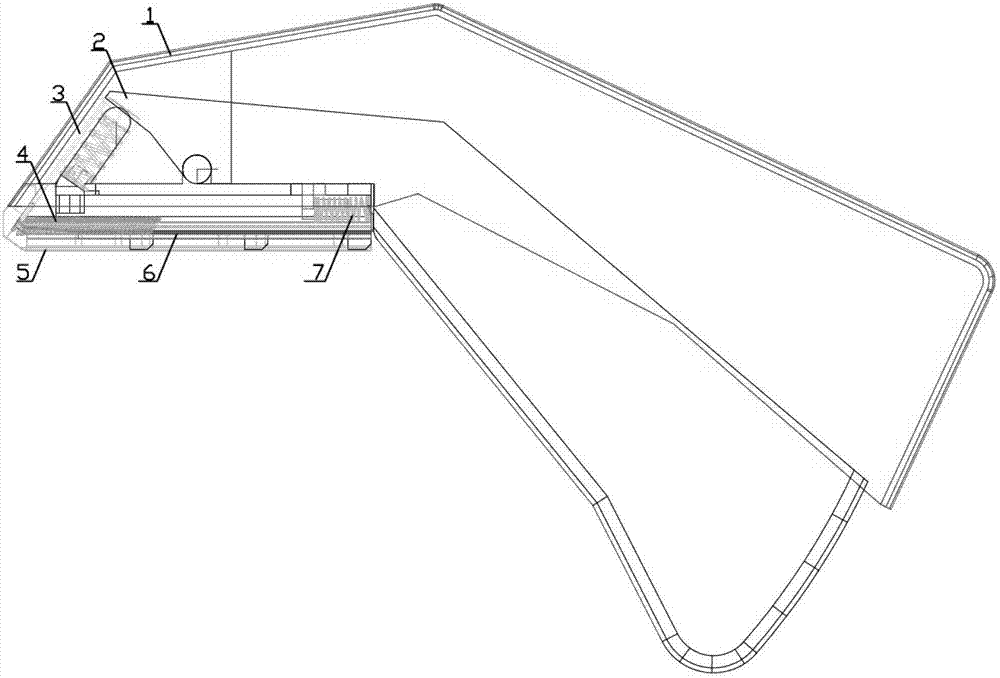

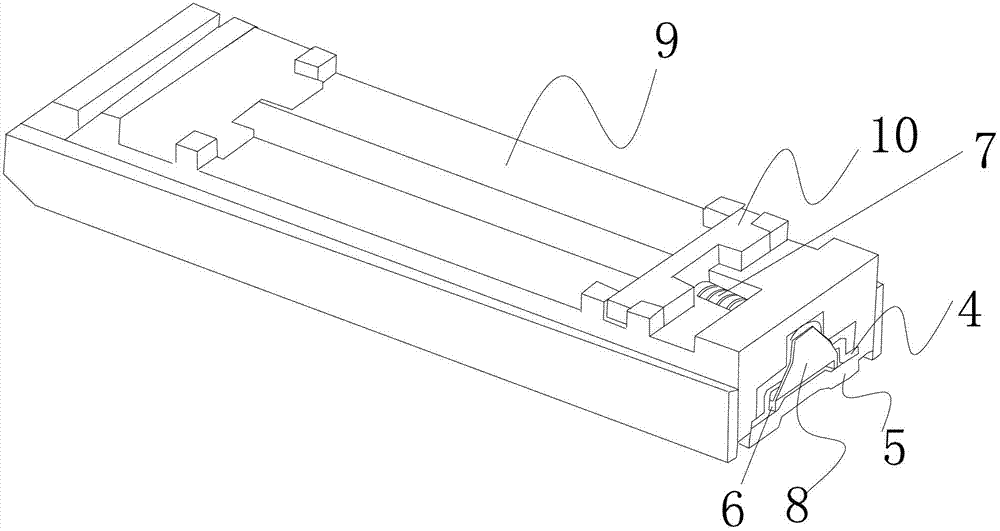

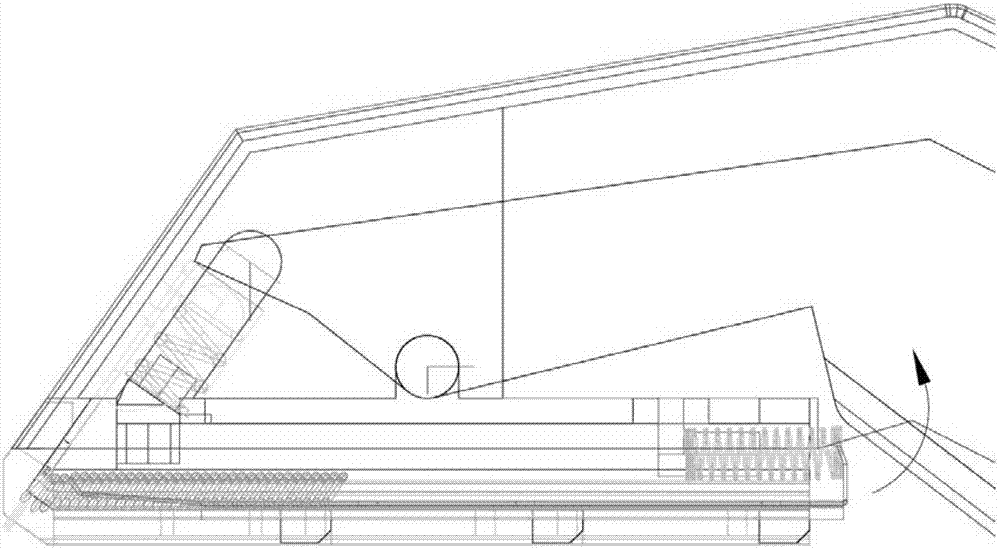

[0023] A spring automatic needle-off structure skin stapler, including a handle and an inner suturing mechanism arranged in the handle, the handle includes an upper handle 1 and a lower handle 2, and the inner suturing mechanism includes an upper needle box 9, a needle guide plate 4 and a lower needle box 5, The upper needle box 9 and the lower needle box 5 are interlocked, the needle guide plate 4 is arranged between the upper needle box 9 and the lower needle box 5, and the needle removal mechanism is arranged between the needle guide plate 4 and the lower needle box 5, and the needle is removed The mechanism is slidingly matched with the needle guide plate 4 and the lower needle box 5, and the rear part of the needle removal mechanism is fixed with a spring mechanism for resetting the needle removal mechanism.

[0024] The needle removal mechanism is a needle removal plate 6, the spring mechanism includes a spring 7 and a spring stopper 10, one end of the spring 7 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com