Differential air-pressure spray dust removing system and implementation method thereof

A technology for dust removal system and realization method, applied in the direction of separation method, chemical instrument and method, use of liquid separation agent, etc., can solve the problems of high cost, complex structure of dust removal system, no collection and combined use of rainwater utilization, etc., to reduce energy consumption consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] At present, the dust removal and cooling systems used in highway construction and urban construction are very complex in structure, and require an external power supply or other power source to provide power for the dust removal system to make the dust removal system work. The cost is not only high, but also the daily maintenance is very high. Inconvenience; and for speed bumps used in highways and communities, motorized and non-motor vehicles will lose part of their power potential energy after decelerating through the speed bumps. After the lost power potential energy is transmitted to the ground, it gradually disappears and is not effectively used. After considering the existing technology of the above two equipment or facilities, the invention designed a new type of dust removal system combining the two through creative work.

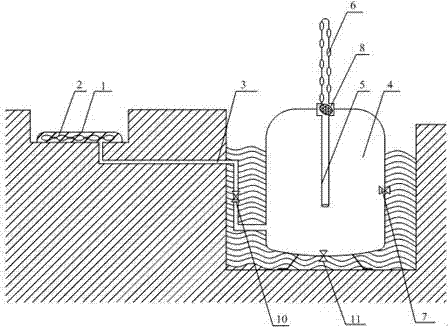

[0039] Such as figure 1 As shown, the differential air spray dust removal system is mainly composed of a speed belt 1 installed on the road, a n...

Embodiment 2

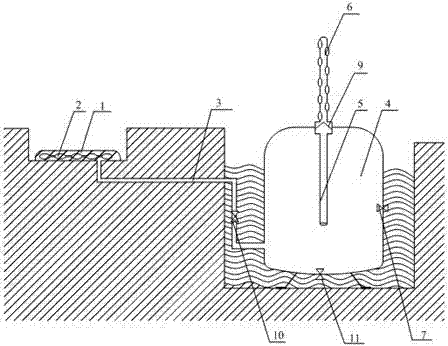

[0047] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is that the diffusion chamber in the pressure release unit is provided with a safety valve 9, which unilaterally opens outwards through the air pressure difference between the tank and the outside, and only allows water flow and air pressure Flow to the upper end of the guide tube 5.

Embodiment 3

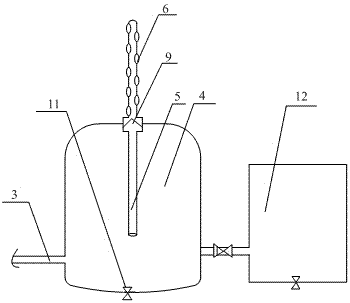

[0049] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that a sedimentation filter tank 12 is added, and the sedimentation filter tank 12 is connected to the water storage pressure tank 4, which can be used to store water on the one hand, and then remove the water. Sedimentation filtration makes the water sprayed by the dust removal system cleaner and environmentally friendly; on the other hand, adding water to the sedimentation filter tank can ensure that the dust removal system can work normally at any time, avoiding the defects of insufficient precipitation in the area that affect the dust removal operation of the dust removal system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com