Automatic flanger

An automatic turning and edge machine technology, which is applied in the field of turning equipment, can solve the problems of low work efficiency, inability to adapt to modern technology, and difficult integration into assembly line operations, etc., and achieve the effect of high work efficiency, low labor intensity and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

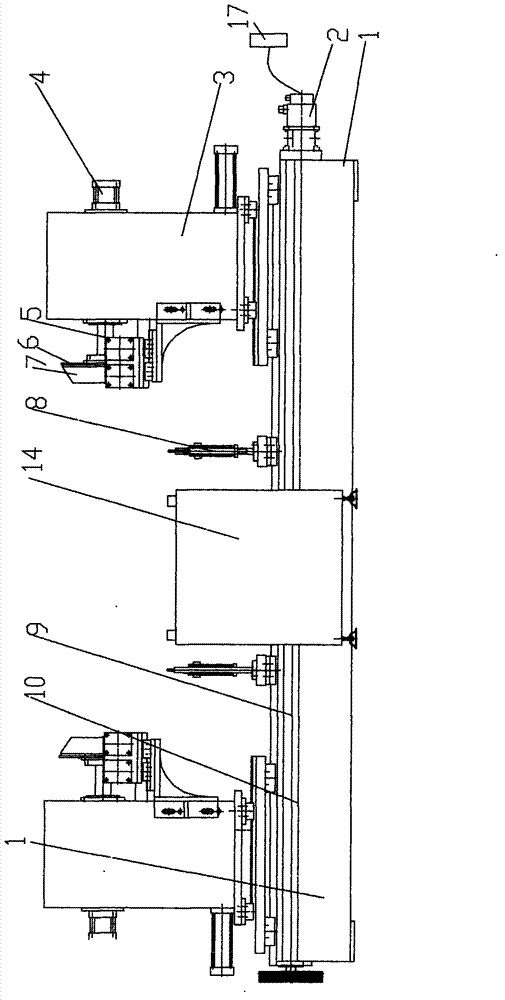

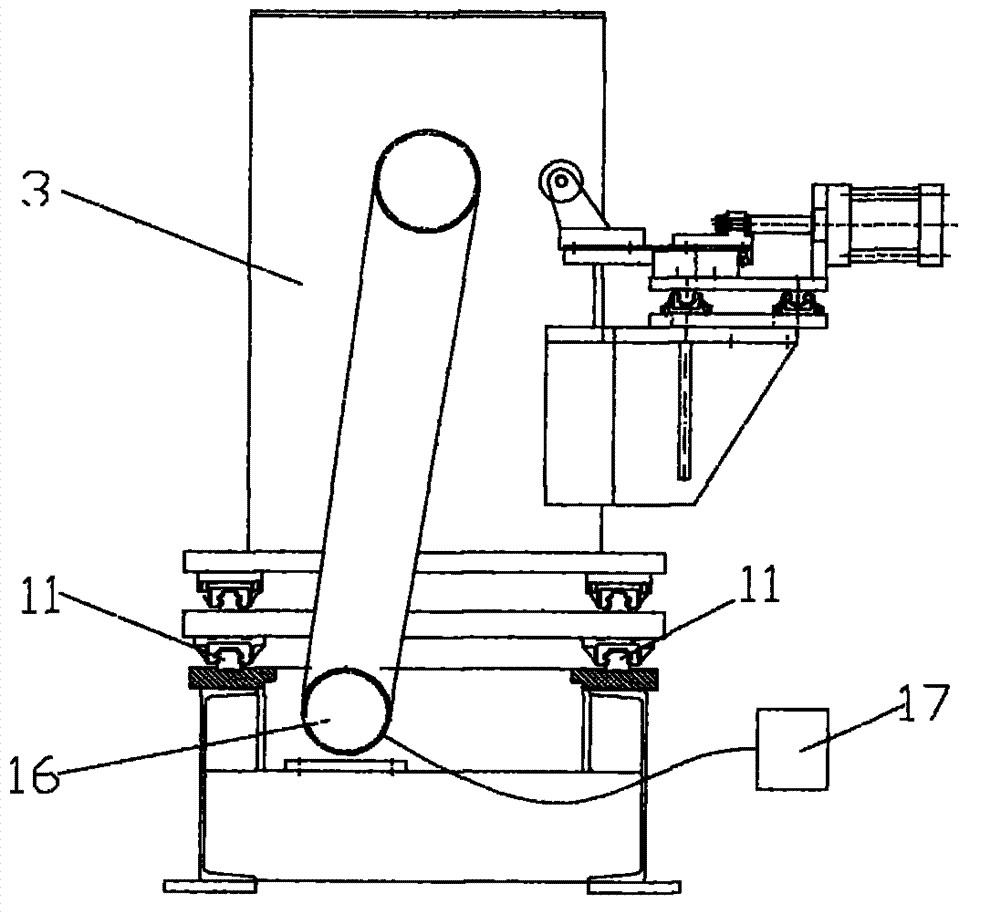

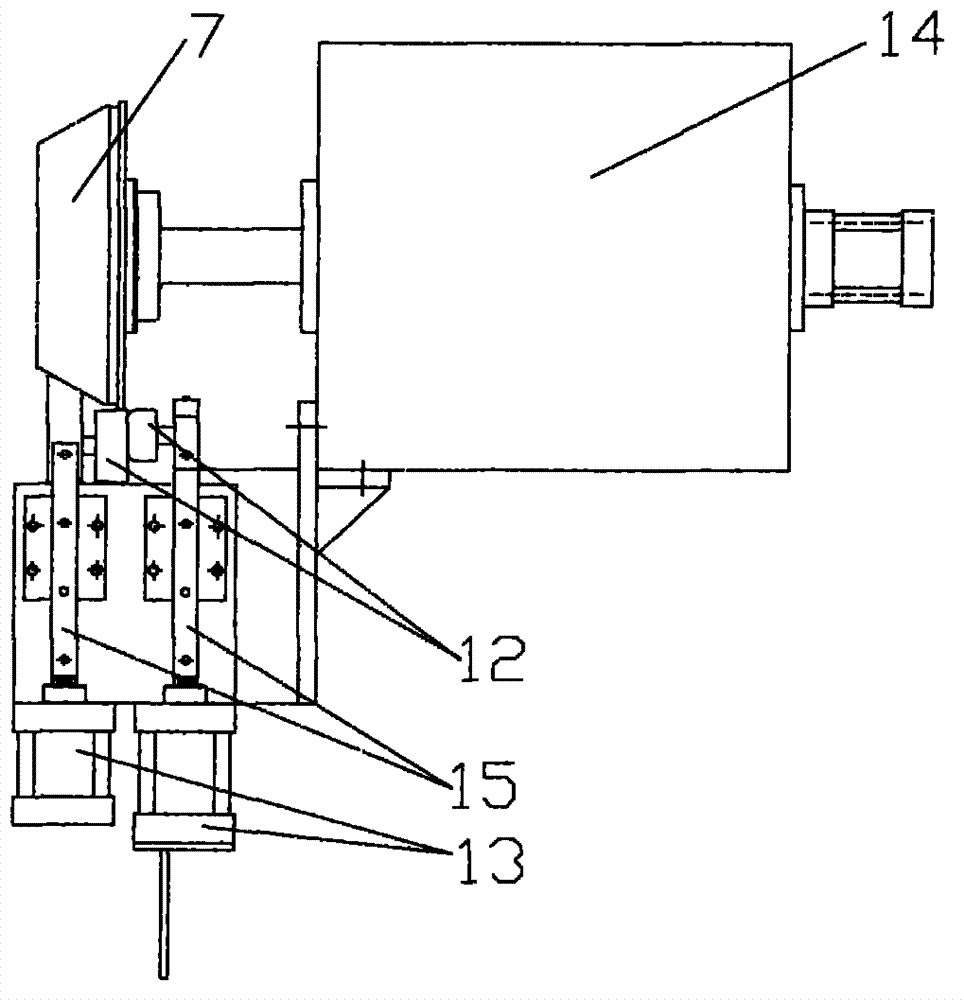

[0014] Such as figure 1 , figure 2 , image 3 Shown: an automatic flanging machine, including a machine base 1 and a feeding frame 14, the machine base 1 is one, respectively connected to both sides of the material feeding frame 14, the machine base 1 is provided with a box body 3, a rotating transmission mechanism, Flanging mechanism, supporting mechanism, ball screw 10 and servo motor 2, the rotary transmission mechanism and servo motor 2 are connected with PLC programmable controller 17 through wires, and ball screw 10 and servo motor 2 can be adjusted arbitrarily according to different workpiece specifications The distance between the box body 3 on the two machine bases 1, the ball screw 10 and the servo motor 2 are equipped with an automatic locking device, the machine base 1 is provided with a linear guide rail 11, and the box body 3 is set on the guide rail 11 of the machine base 1 , the box body 3 is provided with the main shaft 5, the flanging cylinder 13, the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com