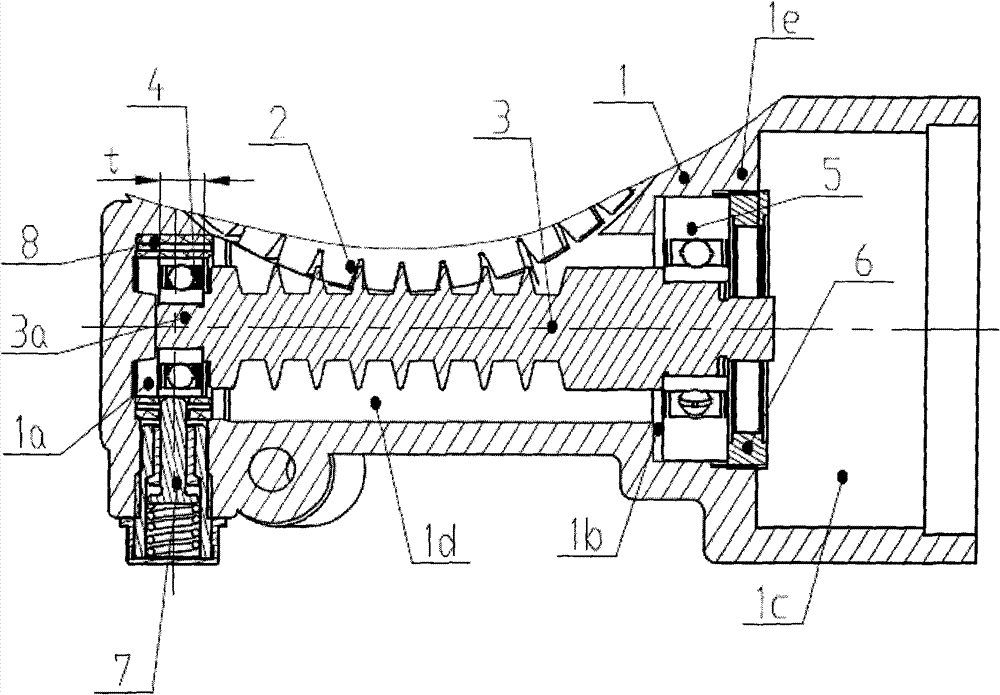

Automatic clearance adjusting mechanism for worm and gear of automobile electric power steering gear

A technology of electric power steering and worm gears, which is applied in the direction of electric steering mechanisms, mechanical steering gears, mechanical equipment, etc., can solve problems such as changes in the meshing gap of worm gears, affecting the meshing performance of worm gears, and affecting the handling stability of automobiles, etc., to achieve The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

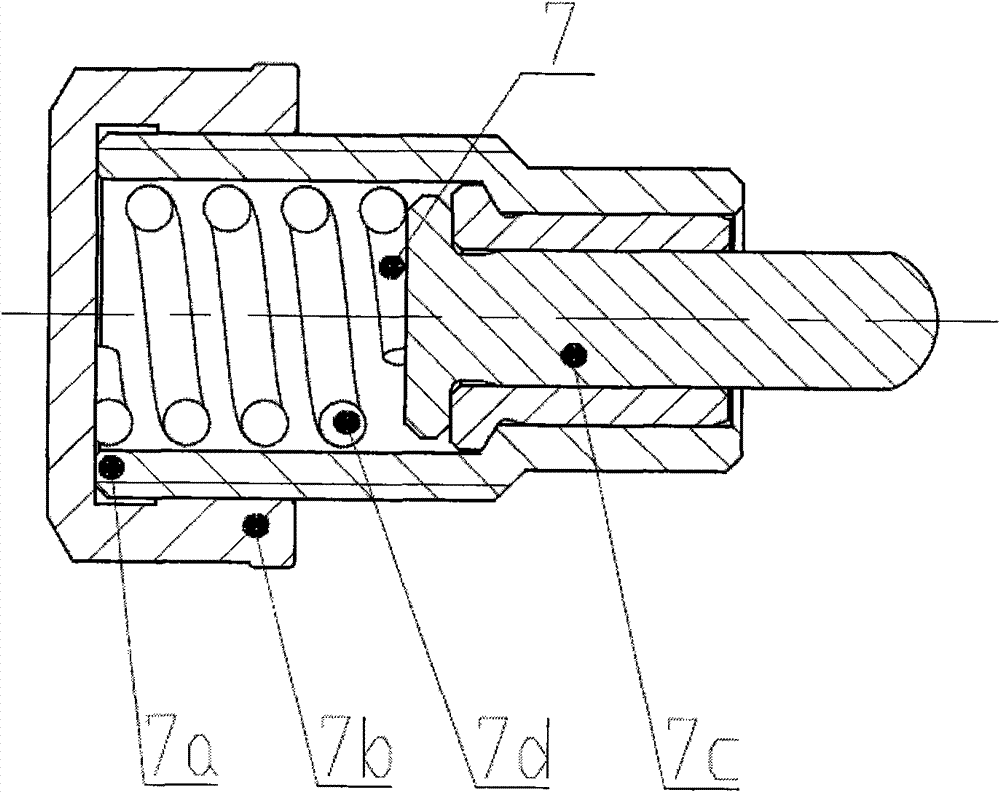

[0020] Said worm top bearing 5 is a self-aligning ball bearing, and its model is: 1302.

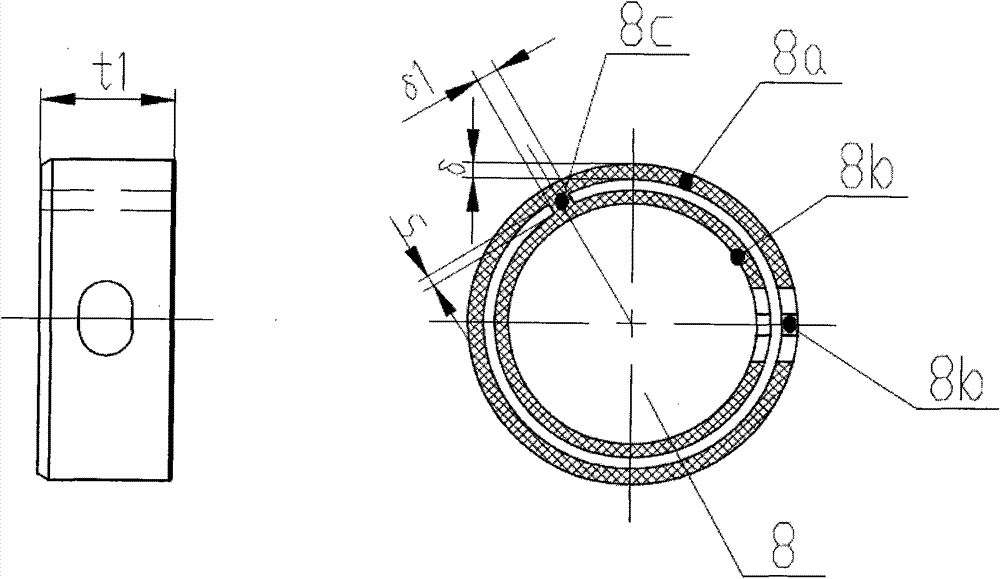

[0021] The adjustment ring 8 is made of PA6 nylon material, and the parameters of the adjustment ring 8 are as follows:

[0022] t=7mm, t1=12mm, δ=1.4mm, δ1=2mm, s=0.95mm. The number of connecting ribs 8c is 2, and the included angle between the central line of the connecting ribs 8c and the axis of the ejector pin hole 8d is 75°.

Embodiment 2

[0024] The said worm top bearing 5 is self-aligning ball bearing, its model is: 1302TN1

[0025] The adjustment ring 8 is made of PA66 nylon material, and the parameters of the adjustment ring 8 are as follows:

[0026] t=7mm, t1=9mm, δ=1.4mm, δ1=1.2mm, s=1.5mm. The number of the connecting rib 8c is one, and the included angle between the center line of the connecting rib 8c and the axis of the ejector hole 8d is 60°.

Embodiment 3

[0028] Said worm top bearing 5 is a self-aligning ball bearing, and its size is: the outer diameter is 42mm, the inner diameter is 15mm, and the width is 10mm.

[0029] The adjustment ring 8 is made of PA12 nylon material, and the parameters of the adjustment ring 8 are as follows:

[0030] t=8mm, t1=12mm, δ=2.5mm, δ1=3mm, s=1.7mm. The number of the connecting rib 8c is one, and the included angle between the central line of the connecting rib 8c and the axis of the ejector pin hole 8d is 75°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com