Building garbage baking-free brick or building block and preparation method thereof

A technology for construction waste and non-burning bricks, which is applied in the field of building decoration materials, can solve problems such as construction waste polluting the environment, and achieve the effects of less energy consumption, high strength and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

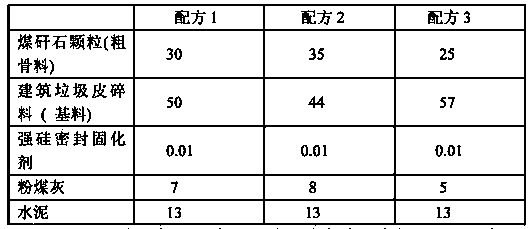

[0015] A construction waste unburned brick or building block described in the embodiment of the present invention is made of the following raw materials: 30-57 kg of construction waste crushed material, 25-50 kg of coal gangue particles, 8-15 kg of cement, pulverized coal Ash 3-18 kg, strong silicon sealing and curing agent 0.01-0.025 kg and water 8-12 kg. The construction waste crushed material is the solid that has been screened, removed metal objects and crushed to a particle size below 1.5 mm, modified with a modifier at a mass ratio of 100:11, and then stacked and purified for 1-3 days For construction waste, the improving agent is made of the following raw materials in parts by weight: 15 parts of ferrous sulfate, 15 parts of magnesium sulfate, 70 parts of quicklime and 0.1 part of potassium permanganate. The cement is Portland cement, sulphoaluminate cement, glass fiber reinforced cement (GRC), self-stressing iron-aluminate cement or white cement, colored cement or magn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com