Submicron 4A type molecular sieve and preparation method thereof

A submicron molecular sieve technology, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the secondary pollution of waste slag, waste alkali and waste liquid, the overall cost needs to be further reduced, and ultrasonic waves are needed and other issues, to achieve the effect of reducing environmental pollution, saving material costs, process and equipment requirements are not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

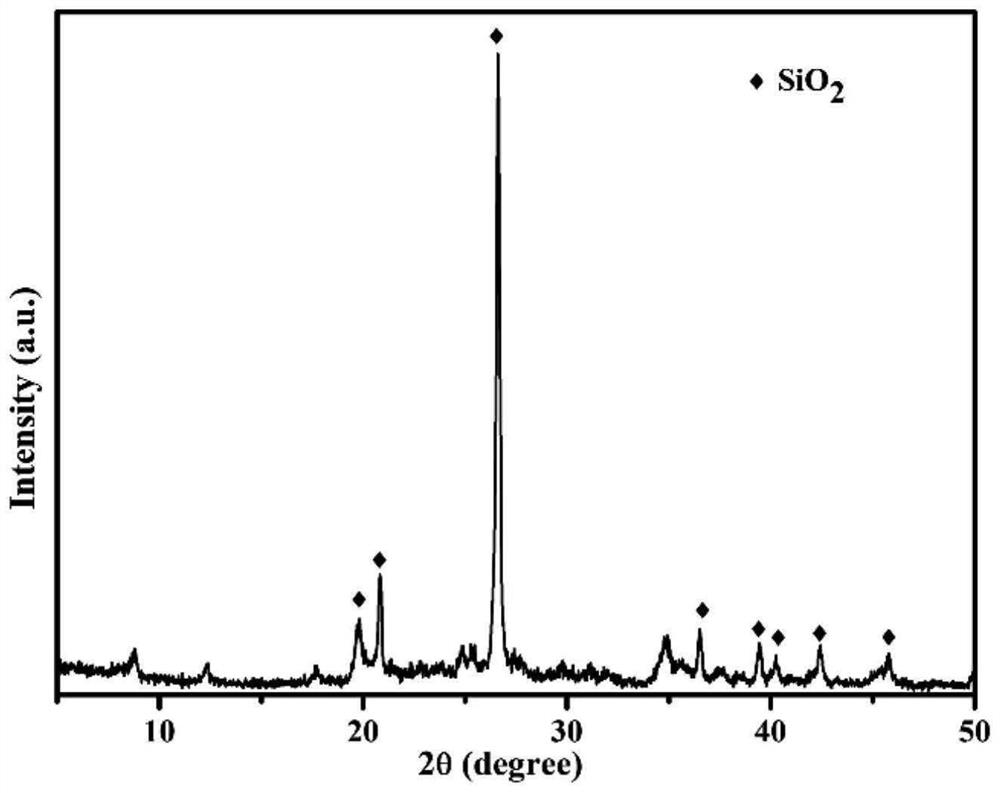

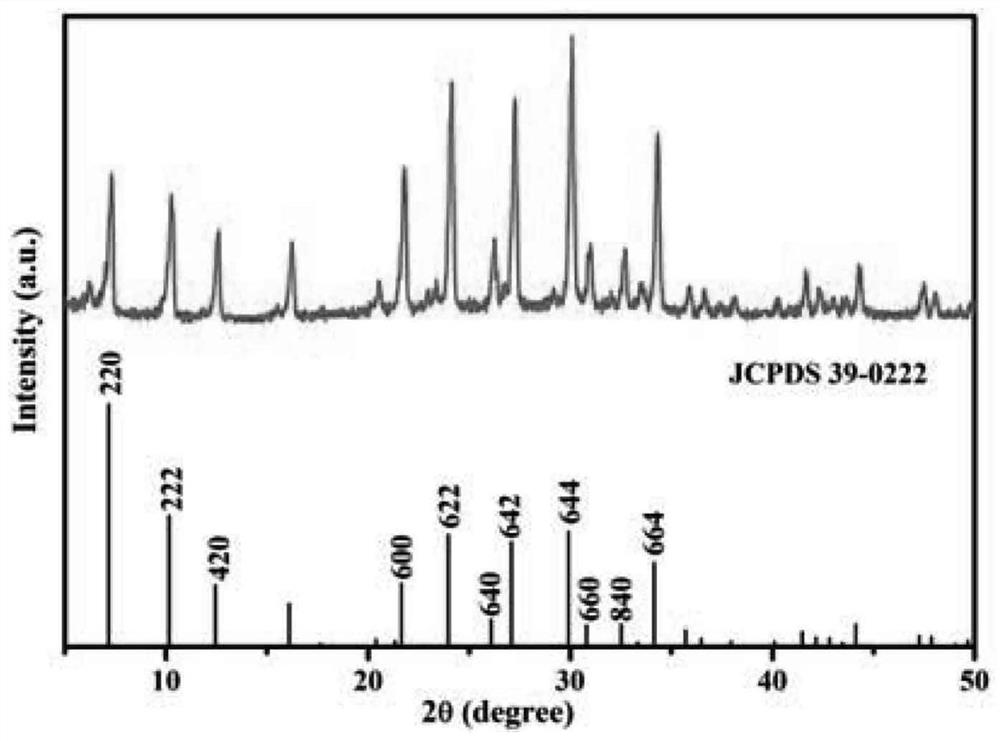

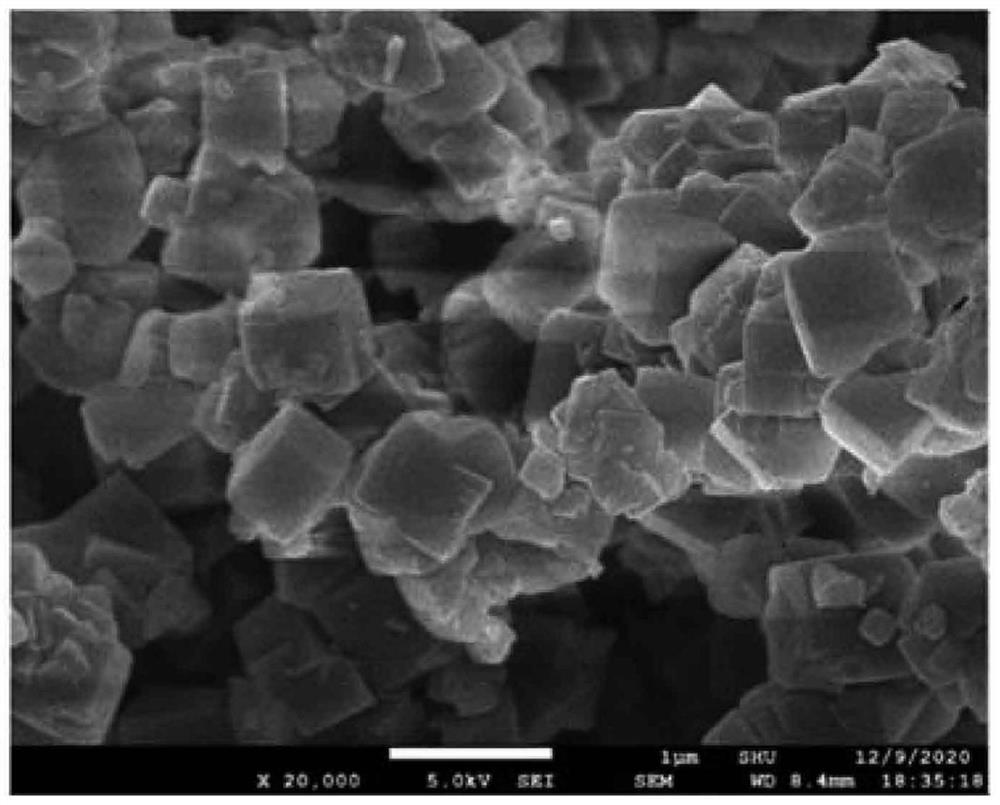

[0034] Please see attached Figure 1 ~ Figure 3 , the first submicron 4A molecular sieve method provided in this embodiment is to prepare a cubic 4A molecular sieve, which includes the following steps:

[0035] S1: Prepare quartz-rich coal gangue whose main mineral phase is quartz phase;

[0036] S2: Activate coal gangue: Calcinate the gangue to remove carbon elements and sieve it, mix it with solid NaOH at a ratio of 1:1 to 1:1.5, place it in a muffle furnace for calcination, then take it out and grind it, and then secondary calcination;

[0037] Specific steps: calcinate the gangue at 650°C for 2 hours, remove carbon elements and sieve through 200 meshes, then take 4g of the gangue after treatment, mix evenly according to the ratio of gangue: NaOH=1:1.5; place in Calcined in a muffle furnace at 250°C for 1 hour, then took it out and ground it, mixed it evenly, put it in the muffle furnace again, and calcined at 400°C for 2 hours, so that the quartz and alkali in the coal g...

Embodiment 2

[0048] The embodiment of the present invention provides the second submicron 4A molecular sieve method, which is to prepare a spherical 4A molecular sieve, which includes the following steps:

[0049] S1: Prepare quartz-rich coal gangue whose main mineral phase is quartz phase;

[0050] S2: Activated gangue: Calcinate the gangue to remove carbon elements and sieve it, mix it with solid NaOH at a ratio of 1:1 to 1:1.5, place it in a muffle furnace for calcination, then take it out and grind it, and then calcined;

[0051] S3: Alkali dissolution of insoluble matter: Weigh a set amount of solid NaOH and add deionized water to fully dissolve NaOH to obtain a NaOH solution, add the product in the above step S2 to the NaOH solution, and obtain a mixture after aging at room temperature; Suction filtration of the mixture to separate the solid from the liquid and filter out impurities; then add the filtered impurities to the coal gangue in step S1 for reuse, repeat this process, and f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com