Set bearing platform foundations and construction method thereof

A technology of foundation construction and construction method, applied in the direction of basic structure engineering, construction, etc., can solve problems such as difficult construction operation, difficulty in ensuring project quality and safety, slow construction progress, etc., to achieve reduced construction difficulties, reliable construction methods, and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] The pile cap foundation of the present invention is set, and its preferred embodiment is:

[0020] Including piles, the piles are vertical, the caps are arranged on the top of the piles, the caps are horizontally arranged, the piles and the caps are connected by cast-in-place concrete, and the bottom of the cast-in-place concrete Equipped with a temporary water-tight air bag.

[0021] The pile includes a lower section pile and an upper section pile, the cross section of the upper section pile is circular, and the diameter is larger than that of the lower section pile, the upper section pile is a steel pipe and reinforced concrete composite material structure, and the lower section pile is a reinforced concrete structure. The bearing platform is an integral reinforced concrete structure, and the temporary water-stop air bag is inflated rubber.

[0022] The outer layer of the upper pile is a steel pipe with multiple horizontal circular flat steel welded on the inner wall...

specific Embodiment

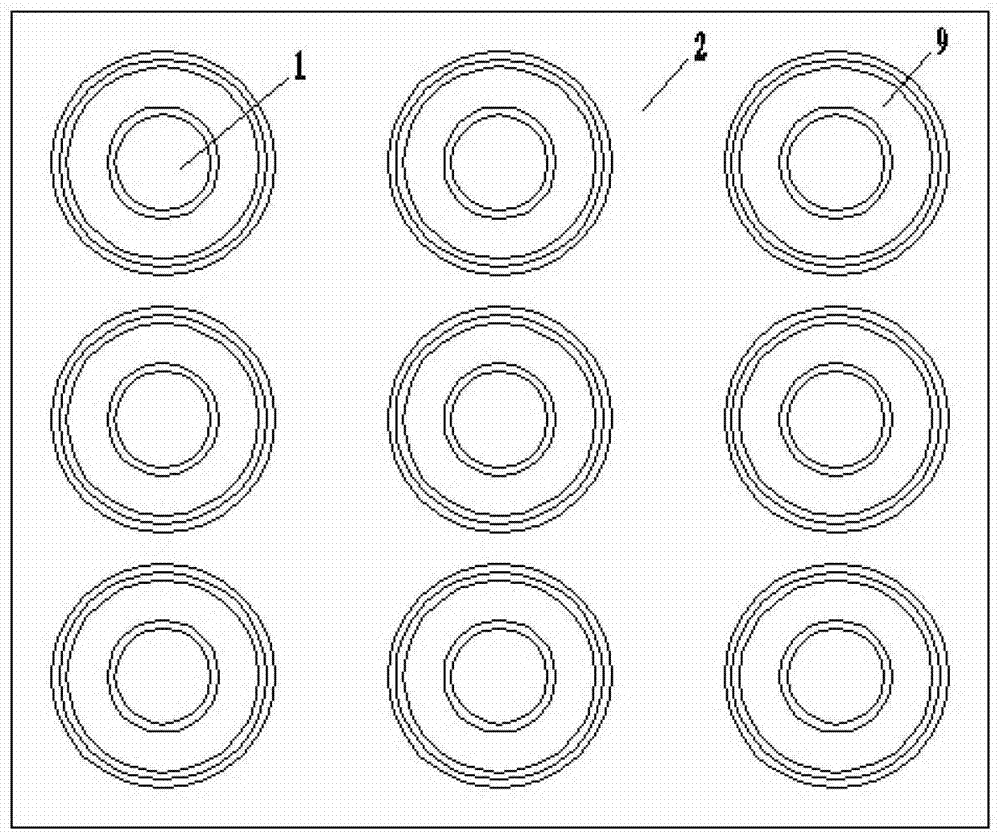

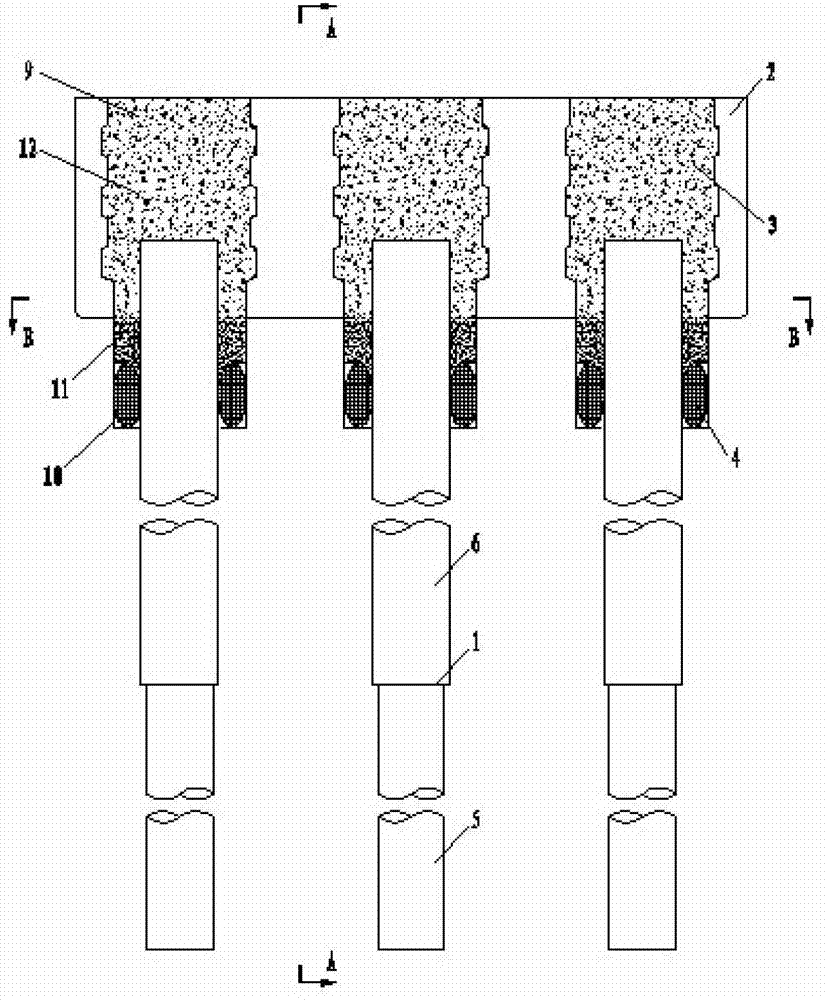

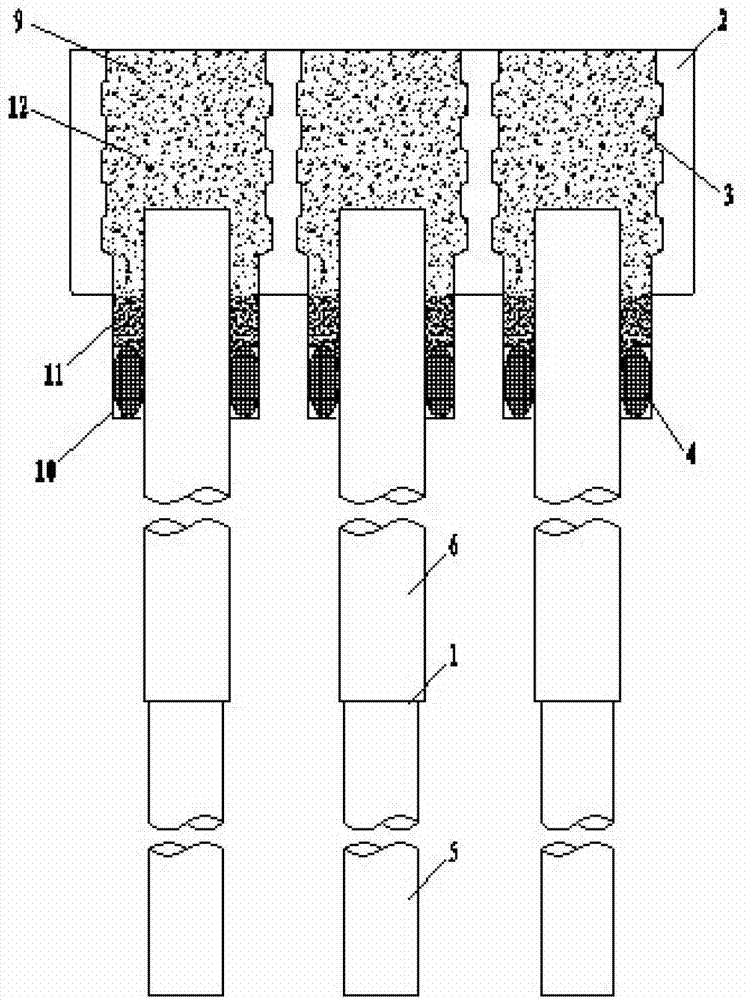

[0034] Such as Figure 1 to Figure 6 As shown, the number of piles 1 determined according to the design calculation is included. The piles 1 are all vertical. The deck 2 is set horizontally, and the thickness of the deck is 3.5m. The pile 1 and the deck 2 are connected by cast-in-place concrete 3, and the bottom of the cast-in-place concrete 3 is provided with a temporary water-stop air bag 4. During the connection process of pouring the cast-in-place concrete 3, a temporary water-stop air bag 4 is used to stop water.

[0035] The pile 1 includes a lower section pile 5 and an upper section pile 6, the cross section of the upper section pile 6 is circular, the lower section pile 5 is a reinforced concrete structure, and the pile diameter is 1.2m, and the upper section pile 6 is steel pipe and reinforced concrete Composite material structure with a pile diameter of 1.4m. The platform platform 2 is an integral reinforced concrete structure, and the temporary water-stop air bag ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com