High-precision temperature control system and method

A temperature control system and high-precision technology, applied in the field of energy systems, can solve the problems of ineffective utilization of cooling capacity of air-cooled units, unguaranteed temperature uniformity of equipment, imperfect temperature control system, etc., so as to save the temperature control process. time, is conducive to integration and miniaturization, and has the effect of large specific heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

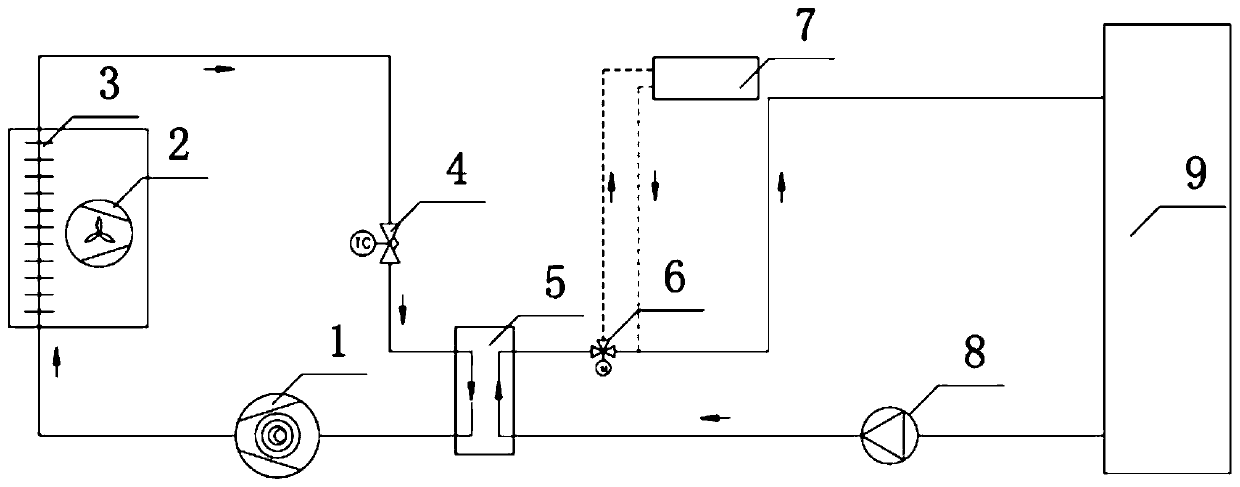

[0048] The difference between this embodiment and Embodiment 1 is that this embodiment provides a high-precision temperature control method, including:

[0049] S1: Increase the temperature of the refrigerant

[0050] Increase the temperature of the refrigerant through the principle of vapor compression;

[0051] S2:; increase the temperature of the brine

[0052] Pass the refrigerant in S1 into the second heat exchanger 5 to provide heat for the brine, thereby increasing the temperature of the brine;

[0053] S3: Send heat to the temperature-controlled terminal equipment

[0054] The brine in S2 is sent into the fan coil unit 7 and the working plate 9 through the liquid pump 8 to complete the temperature regulation of the terahertz equipment.

[0055]During the heating process, the liquid cooling source equipment adopts the principle of vapor compression heating to increase the temperature of the refrigerant, and the high-temperature refrigerant provides heat for the brine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com