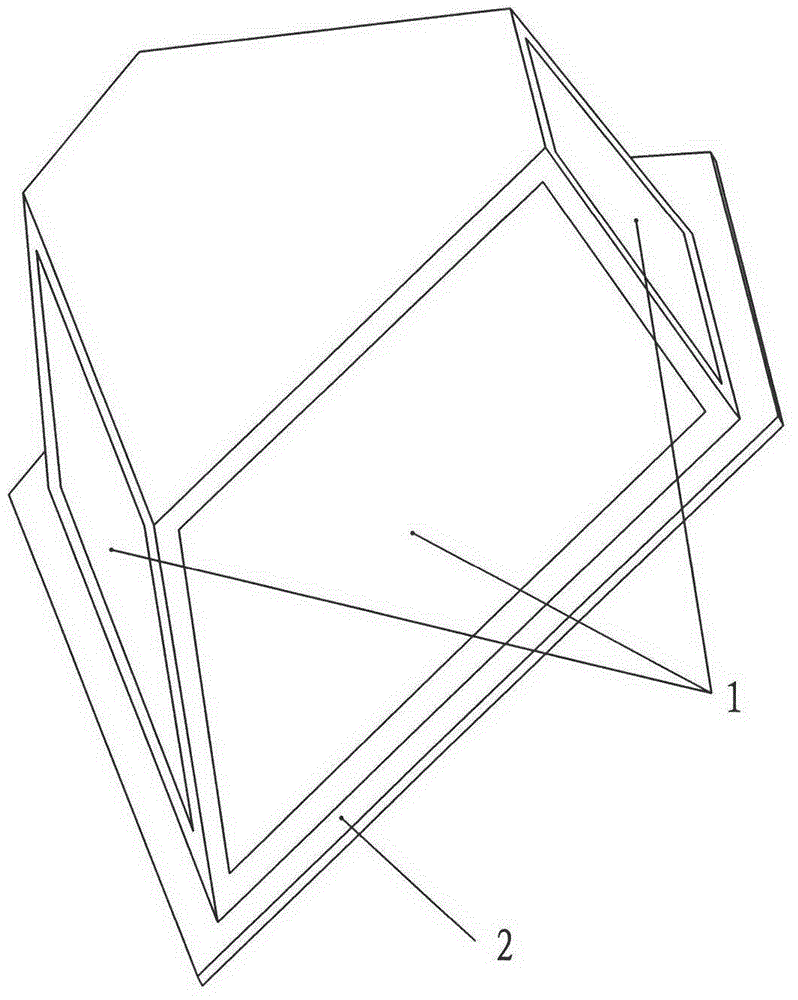

Installation adjusting device suitable for combination optical window testing

A technology of installation adjustment and light window, which is applied in the field of optical testing, can solve the problems of light shading, high manufacturing cost, and difficulty in the installation and alignment of combined light windows, so as to avoid light shading, reduce processing difficulty and cost, and install and lock convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

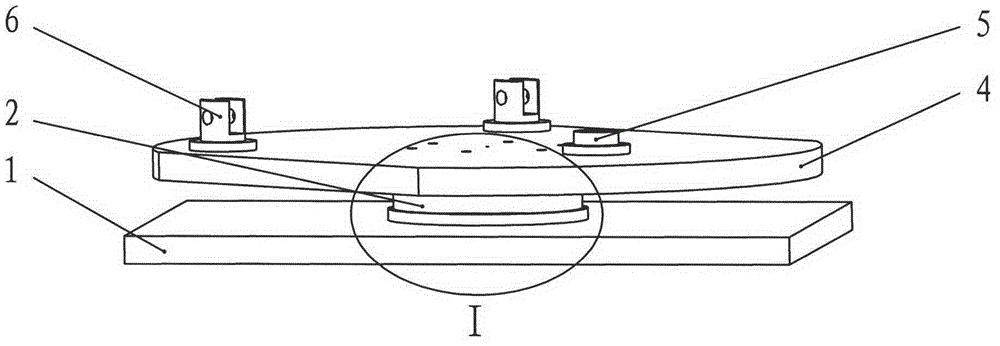

[0027] The installation adjustment device provided by the preferred embodiment of the present invention is composed of a base assembly, a rocker assembly, a fine adjustment assembly and a connecting rod 15 .

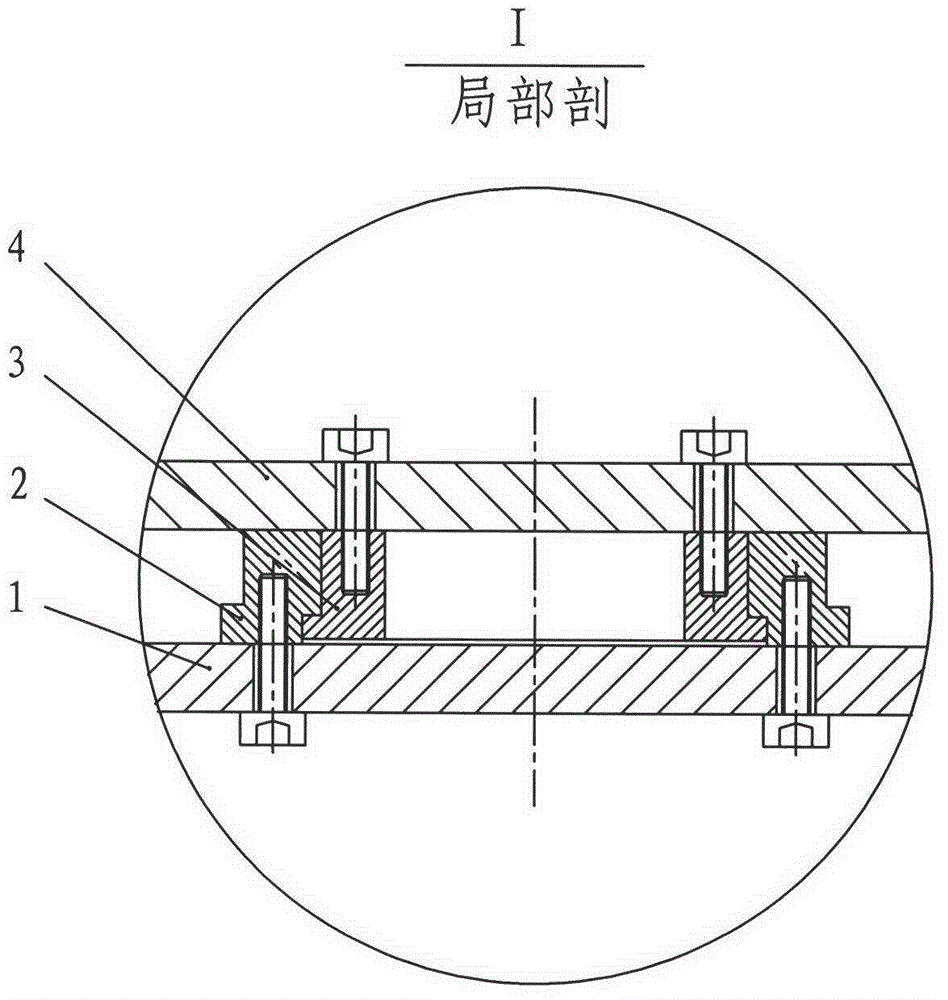

[0028] Such as figure 2 , image 3 As shown, the base assembly includes a lower base plate 1 , an azimuth seat 2 , an azimuth shaft 3 , an upper base plate 4 , a fixed base 5 and two swivel bases 6 . The azimuth seat 2 is a cylinder with a T-shaped hole, the side of the large hole has a circumferential flange and the annular end surface of this side has six screw holes uniformly distributed around the circumference. The azimuth shaft 3 is a T-shaped hollow cylinder with six screw holes evenly distributed around the circumference of the small annular end face. The lower bottom plate 1 is a rectangular thick plate with screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com