Polymer-modified asphalt with a crosslinking agent and methods of preparing

A technology of cross-linked polymers and modified asphalt, which is applied in the direction of cohesive pavement paved on site, building structures, roads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Anti-stripping agents may also be added to the process of the present invention for preparing crosslinked, polymer-modified asphalts or paving compositions containing such asphalts.

[0050] In certain embodiments, the anti-stripping agent is an alkaline anti-stripping agent, preferably slaked lime. Slaked lime contains calcium hydroxide (Ca(OH) 2 ). Commercially available slaked lime is a dry powder obtained by treating quicklime (calcium oxide, CaO) with sufficient water to satisfy its chemical affinity for water to convert the oxides to hydroxides.

[0051] Slaked lime used to prepare the paving composition may be added to aggregate, asphalt, or both according to any suitable method. There are several proven and effective methods of adding slaked lime to asphalt. Examples of this method include injecting hydrated lime into a drum mixer, adding lime to a mud mixer, adding dry hydrated lime to wetted aggregate, or adding lime slurry to wetted or unwetted aggregate (...

Embodiment 1

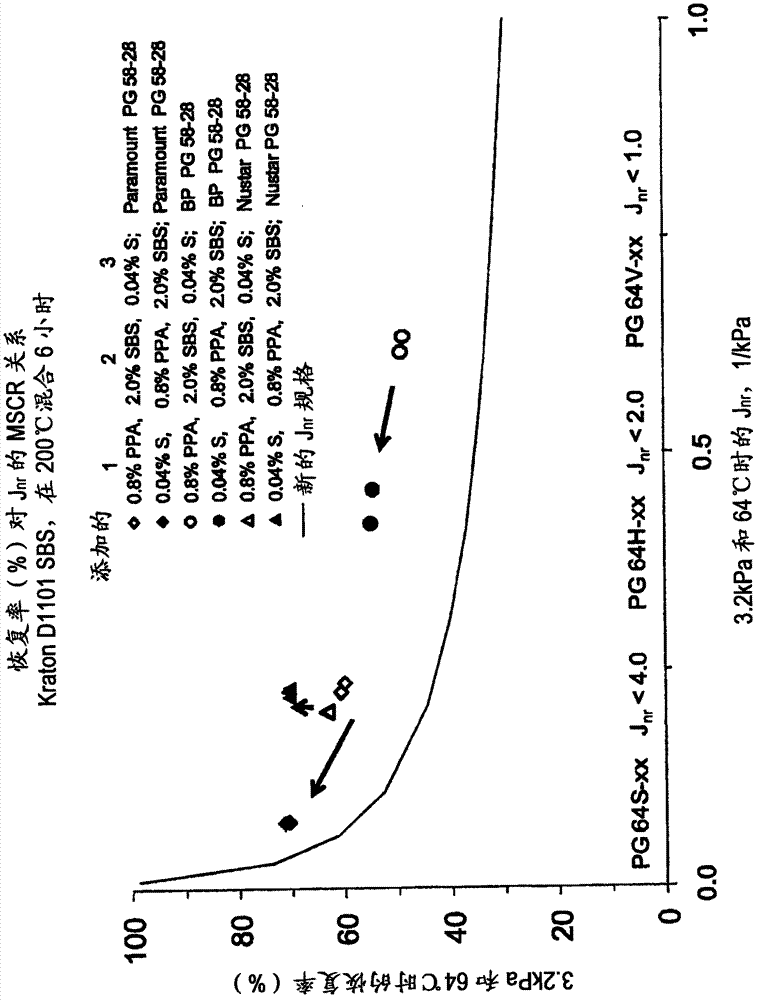

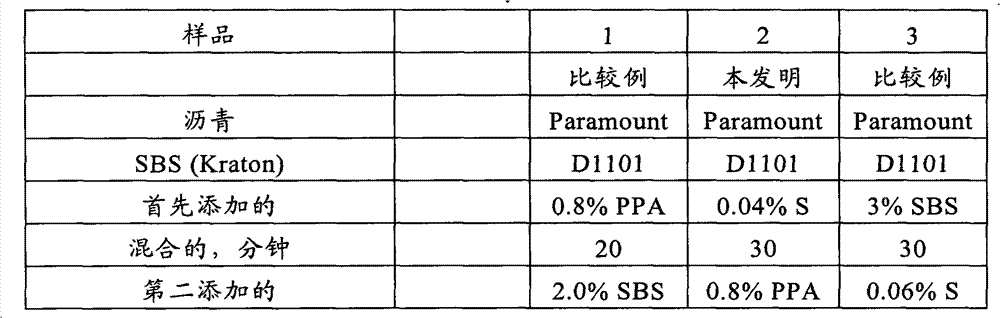

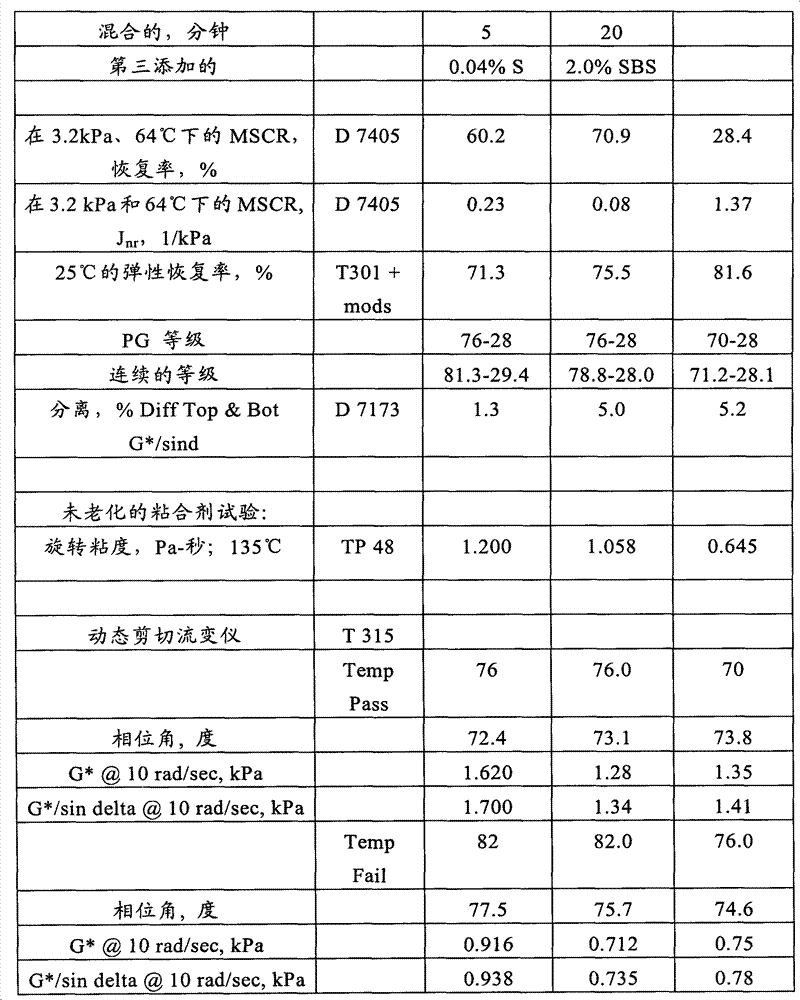

[0095] Tables 1A and 1B show the results using Paramount PG 58-28. In sample 1, polyphosphoric acid was added first, SBS second, and sulfur third. In sample 2, sulfur was added first, polyphosphoric acid second, and SBS third. Concentrations of additives and mixing times between additives are shown in Table 1A. When adding sulfur first, the recovery rate (%) measured by MSCR increased from 60.2 to 70.9, while the non-recoverable creep compliance J measured by MSCR nr From 0.23 to 0.08. Sample 3 tested only SBS polymer and sulfur (no polyphosphoric acid added). The absence of polyphosphoric acid resulted in lower recovery rate (%) and higher non-recoverable creep compliance.

[0096] Table 1A

[0097]

[0098]

[0099] Table 1B

[0100]

[0101]

[0102] Tables 2A and 2B show the results using BP PG58-28. In sample 4, polyphosphoric acid was added first, SBS second, and sulfur third. In sample 5, sulfur was added first, and then polyphosphoric acid and SBS w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com