Production process of falling-apart-resistant silk stockings with human-body aesthetics

A production process and anti-separation technology, applied in the directions of socks, pantyhose, yarn, etc., can solve the problems of difficult processing, inability to get rid of the existing structure, easy to draw silk, etc., achieving low manufacturing cost, easy mass production, Process stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

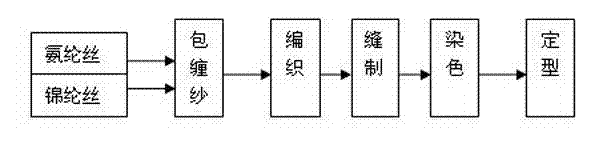

[0024] 1. Wrapped yarn.

[0025] Adjust the temperature of the workshop to 25°C and the relative humidity to 65%. Nylon yarn (other fiber materials can also be selected according to needs) and spandex yarn are used to wrap on a high-speed wrapping machine to make a wrapped yarn suitable for weaving. Among them, the spandex yarn is 20D special spandex (you can also choose other models according to your needs), the nylon yarn is DTY12 / 7 (you can also choose other models according to your needs), the motor speed is 20000 rpm, and the draft ratio is 3.0. The twist is 1900T / M, and the overfeed is 94.5%.

[0026] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0027] 2. Weaving.

[0028] After the wrapped yarn is balanced under certain conditions (generally controlled over 5 days, the temperature is 25°C, and the relative humidity is 65%), it is sent to the computer hosiery machine for weaving and ma...

Embodiment 2

[0038] 1. Wrapped yarn.

[0039] Adjust the temperature of the workshop to 20°C and the relative humidity to 60%. Nylon yarn (other fiber materials can also be selected according to needs) and spandex yarn are used to wrap on a high-speed wrapping machine to make a wrapped yarn suitable for weaving. Among them, the spandex yarn is 40D special spandex, the nylon yarn is FDY / DTY 8D, the motor speed is 20000 rpm, the draft ratio is 3.1, the twist is greater than 1800T / M, and the overfeed is 94%.

[0040] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0041] 2. Weaving.

[0042] After the wrapped yarn is balanced under certain conditions (generally controlled over 5 days, the temperature is 25°C, and the relative humidity is 65%), it is sent to the computer hosiery machine for weaving and made into semi-finished stockings; by adjusting the state of the computer hosiery machine, such as adding Larg...

Embodiment 3

[0052] 1. Wrapped yarn.

[0053] Adjust the temperature of the workshop to 25°C and the relative humidity to 65%. Nylon yarn (other fiber materials can also be selected according to needs) and spandex yarn are used to wrap on a high-speed wrapping machine to make a wrapped yarn suitable for weaving. Among them, the spandex yarn is 60D special spandex, the nylon yarn is FDY / DTY 70D, the motor speed is 20000 rpm, the draft ratio is 3.2, the twist is 2000T / M, and the overfeed is 95%.

[0054] Cover yarn under the situation of above-mentioned temperature and humidity, after equilibrating for 5 days, enter weaving step.

[0055] 2. Weaving.

[0056] After the wrapped yarn is balanced under certain conditions (generally controlled over 5 days, the temperature is 25°C, and the relative humidity is 65%), it is sent to the computer hosiery machine for weaving and made into semi-finished stockings; by adjusting the state of the computer hosiery machine, such as adding Large suction, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com