Device for grinding steering knuckle main shaft

A steering knuckle and spindle technology, which is applied in the field of grinding steering knuckle spindles, can solve the problems of complicated fixing levers and workpiece fixtures, high labor intensity of operators, uneven rotation speed of workpieces, etc., so as to save manual fixing and Disassembly time, high manufacturing cost, effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

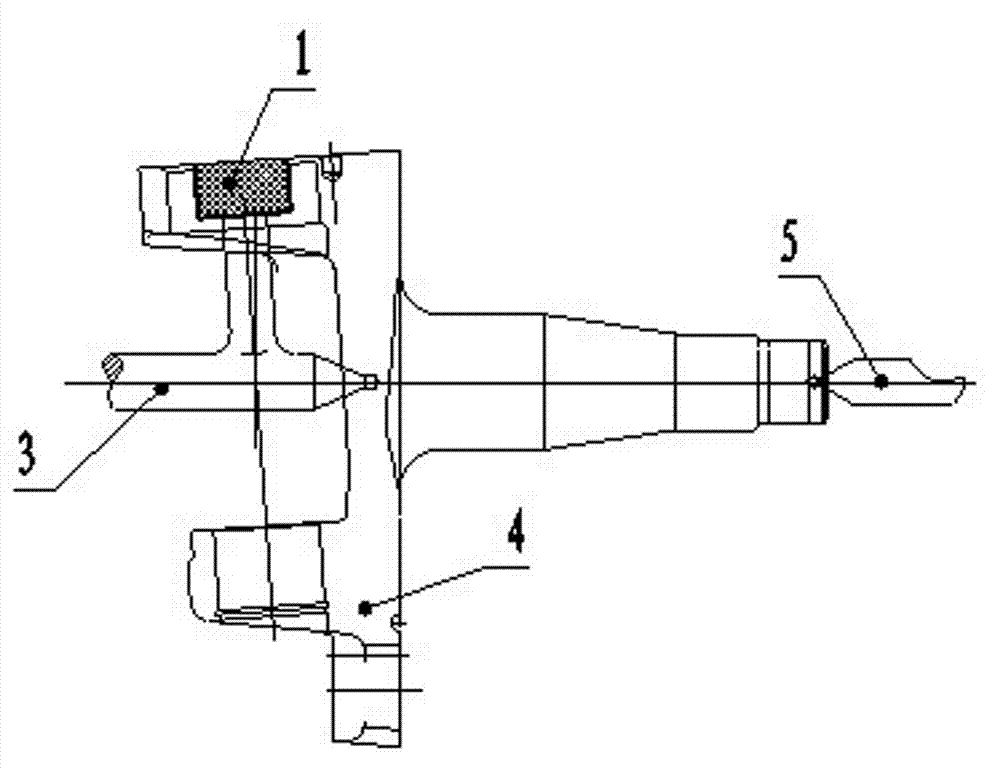

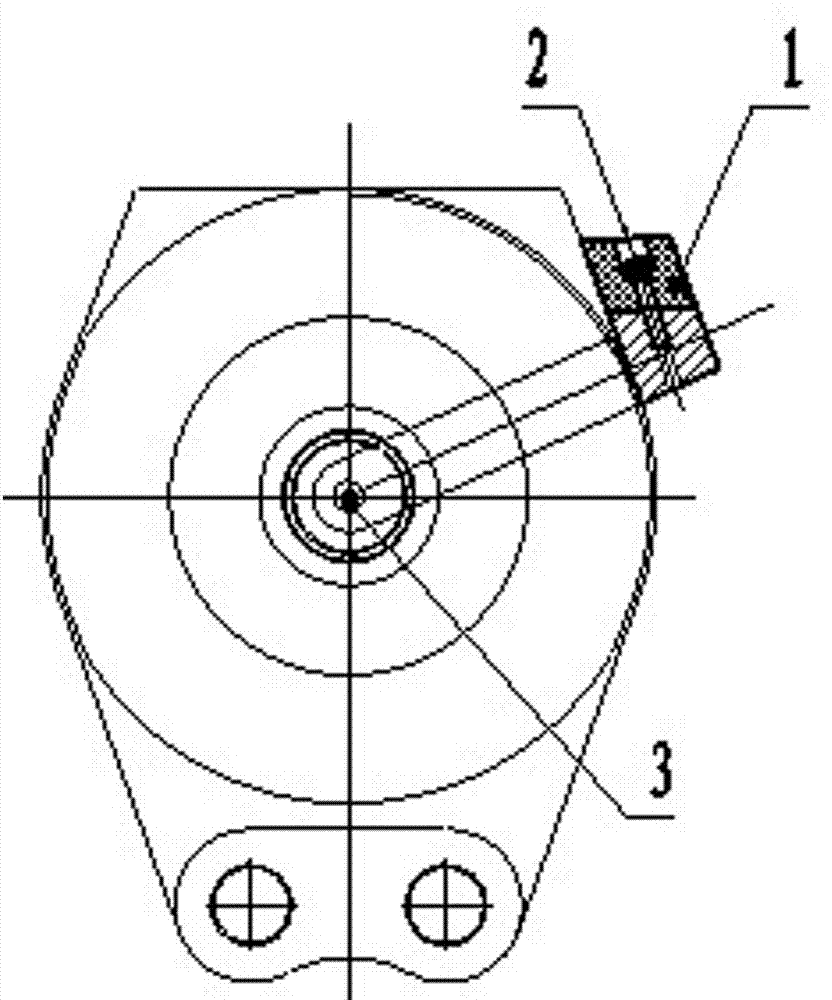

[0013] A device for grinding steering knuckle spindles, such as figure 1 As shown, it includes magnet 1, screw 2, lever tip 3, steering knuckle 4 and rear tip 5, lever tip 3 is installed on the main shaft of the grinding machine, magnet 1 is set on lever tip 3 through screw 2, and rear tip 5 is arranged on the tail stock of the grinder, the steering knuckle 4 is arranged between the top 3 and the rear top 5 of the shift rod, and the magnet 1 is adsorbed on the steering knuckle 4.

[0014] The device uses the natural magnetic force of the magnet to fix and separate the workpiece and the lever, which saves the time for manual fixing and disassembly, and improves the work efficiency by more than 4 times. Oval, surface corrugation, roughness and other quality defects caused by uneven speed, the processed products have high precision and good quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com