Leather picker for loom

A loom and picker technology, which is applied in looms, textiles, textiles and papermaking, etc., can solve the problems of large friction coefficient between the pick rod and picker head, large pick-up force of the loom, and large electric energy, etc. To achieve the effect of promoting the use value, reducing the power of the shuttle, and improving the economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

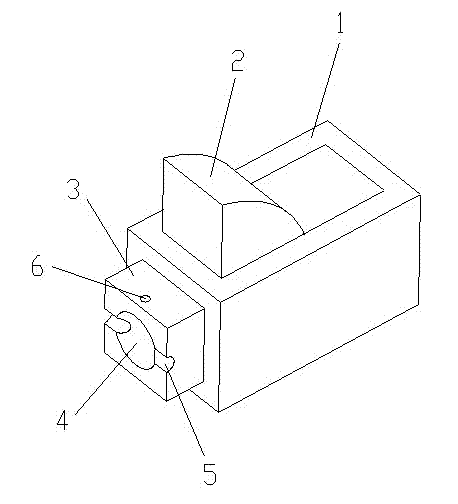

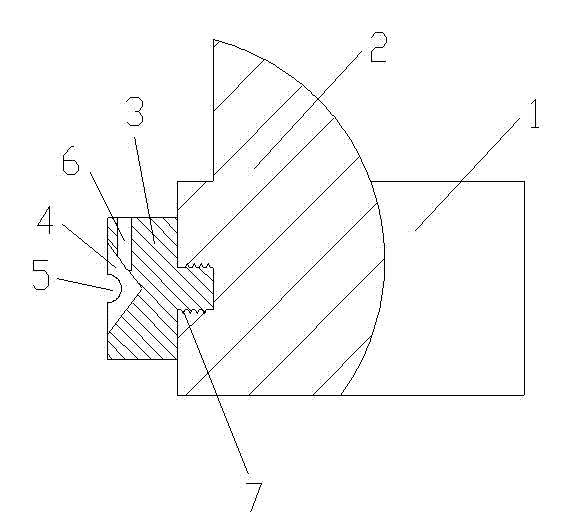

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached figure 1 , 2 A picker for a loom as shown in the present invention includes a picker body 1, a stand kernel 2, and a picker head 3; the picker head 3 is provided with a buffer concave hole 4 and an exhaust groove 5; The picket head 3 is detachably connected to the end of the pickle body 1; the pickle head 3 is provided with an oil seepage hole 6; the oil seepage hole 6 is arranged on the upper part of the buffer concave hole 4; The skin knot head 3 and the skin knot body 1 are connected by threads 7 .

[0014] Due to the application of the above-mentioned technical solution, the present invention has the following advantages compared with the prior art:

[0015] The picker for loom of the present invention, because the picker head is detachably connected to the end of the picker body, when the picker head is damaged, it is only necessary to replace the picker head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com