Anti-flaming floor and production process thereof

A production process and flooring technology, which is applied in the manufacture of tools, wood processing equipment, floors, etc., can solve the problems of no major breakthroughs in flame retardancy, achieve excellent mechanical properties, good mechanical properties, and prevent falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

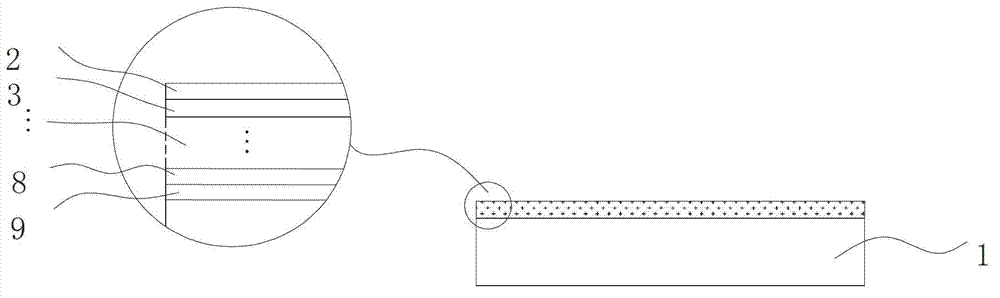

[0044] Embodiment: a kind of flame retardant floor, as attached figure 1 As shown, including a substrate 1, the surface of the substrate 1 is provided with a flame-retardant topcoat layer 2, a second flame-retardant topcoat layer 3, a flame-retardant primer layer 4, a second flame-retardant primer layer 5, sand Light primer layer 6, elastic primer layer 7, putty 8 and water-based adhesive 9.

[0045] As a preference, the flame-retardant topcoat layer 2 and the second flame-retardant topcoat layer 3 can adopt the paint of the model JSRF01 produced by Jiangsu Haitian Technology Co., Ltd.; the flame-retardant primer layer 4 and the second flame-retardant Primer layer 5 can adopt the paint of model JSRF02 produced by Jiangsu Haitian Technology Co., Ltd.; sanding primer layer 6 can adopt the paint of model 128058511 produced by Jiangsu Haitian Technology Co., Ltd.; putty 8 can be produced by Jiangsu Haitian Technology Co., Ltd. The putty of 208068511; the water-based adhesive agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com