Curve coating process method for building decoration

A coating process and architectural decoration technology, which is applied in the direction of architecture, building structure, window/door frame, etc., can solve problems such as poor operation, increased labor and material costs, and inability to standardize mechanized production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

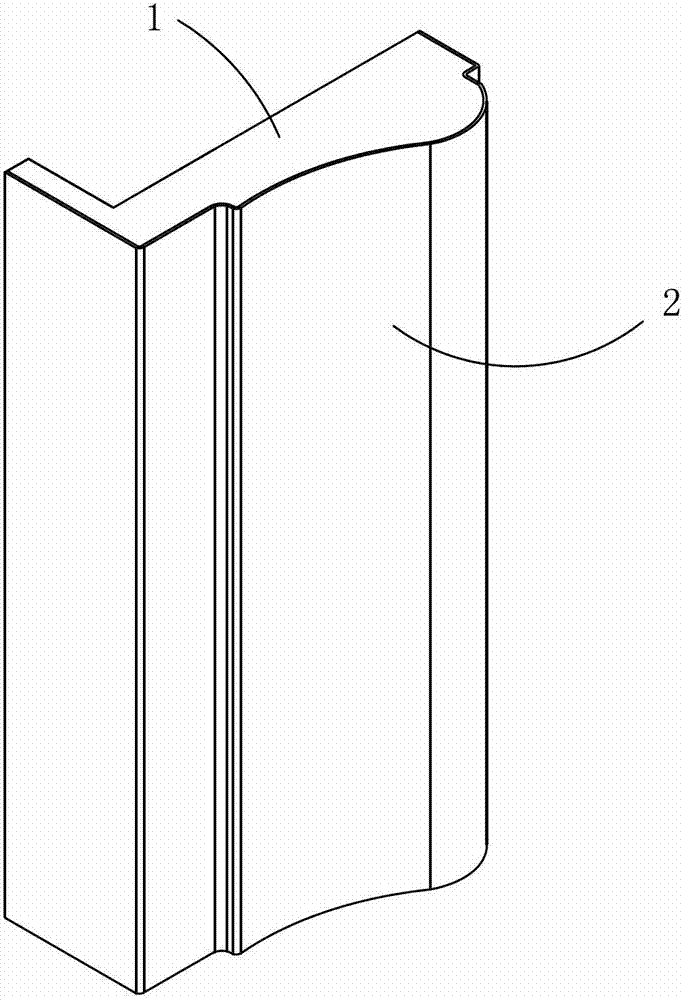

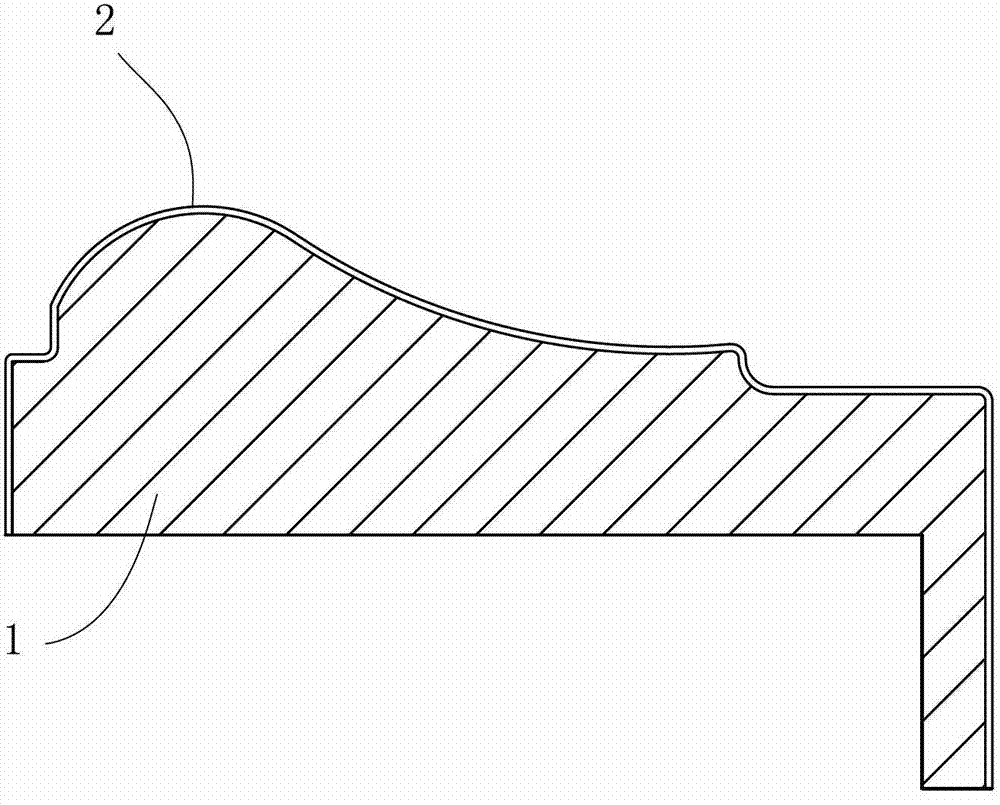

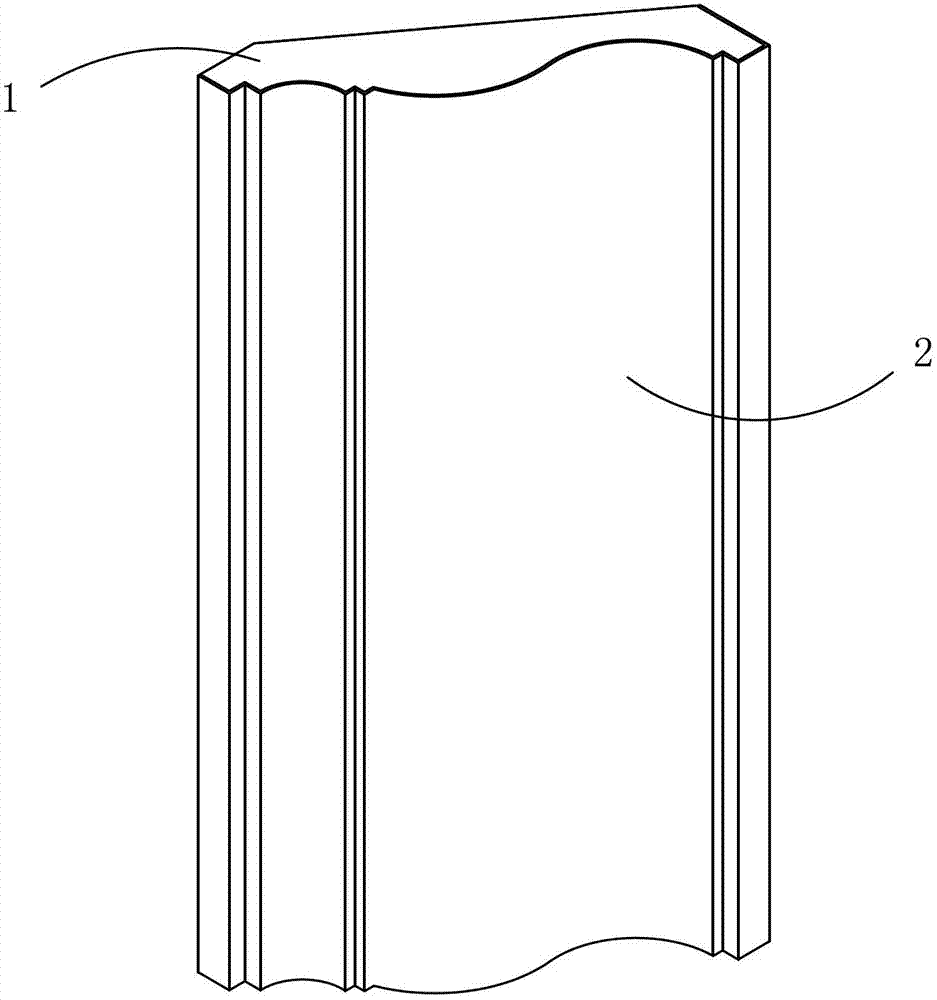

[0012] The curved surface coating process of architectural decoration of the present invention is to first use the base material to form a curved surface shape, and then coat the workpiece that is pasted with solid veneer, for example, Figure 1-2 The door cover line with curved surface shape, Figure 3-4 Ceiling moldings shown with surface molding.

[0013] Step 1: First place the solid wood veneer 2 on a flat workbench for sanding, then brush the primer; repeat the steps of sanding and brushing the primer once or twice or three times; then sand and then brush Topcoat; repeat the steps of sanding and brushing the topcoat at least one more time or two or three times. Repeat once for the coating process of two bottoms and two sides, repeat twice for the coating process of three bottoms and three sides, and repeat three times for the more complicated coating process of four bottoms and four sides.

[0014] Step 2: After waiting for the paint on the solid wood veneer to dry, pa...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap