Novel resistance-reducing structure of high-speed surface

A high-speed, new technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve the problems of large flow resistance and high energy consumption, and achieve the effects of reducing flow resistance, wide application range, and reducing relative motion speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

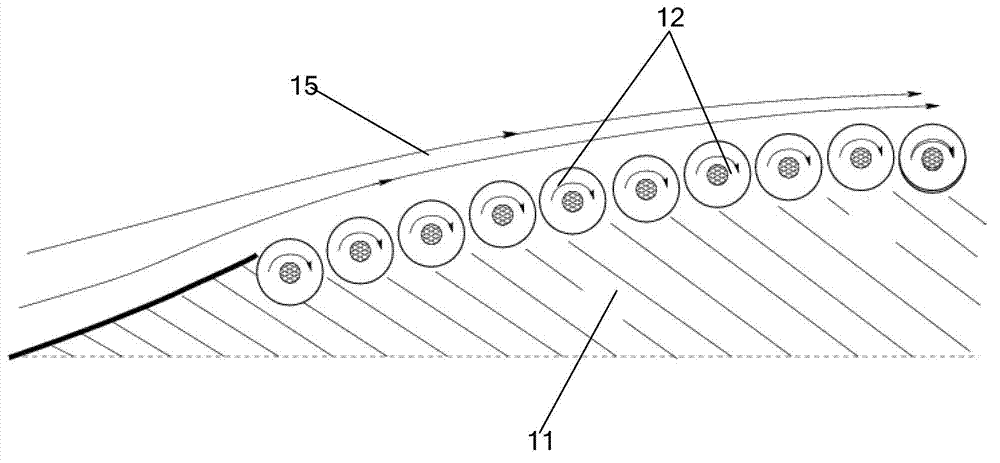

[0021] The novel surface drag-reducing structure of the present invention can be arranged on the surface of the ship immersed in the water body.

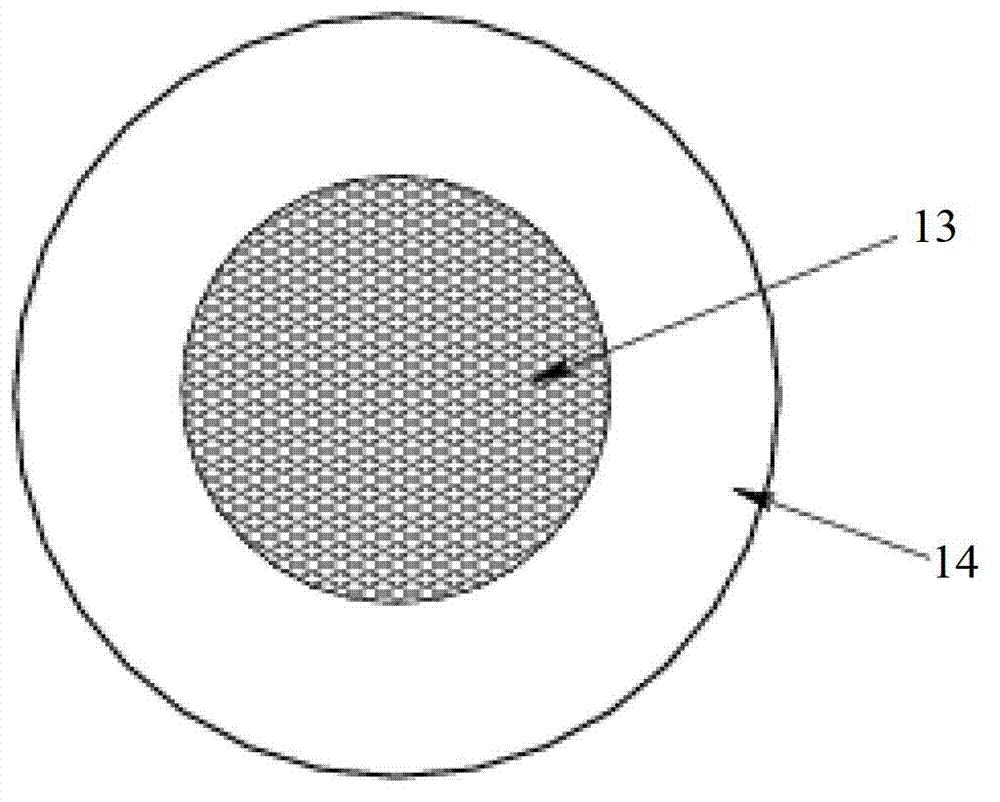

[0022] Usually, the speed of the ship is not very high, but because the dynamic viscosity coefficient of water is much larger than that of air, the drag reducing effect of the drag reducing structure of the present invention is very obvious. In this embodiment, the rotating body 14 may adopt a roller structure on a relatively smooth surface, and may adopt a roller structure on a part of a relatively curved water-immersed surface.

Embodiment 2

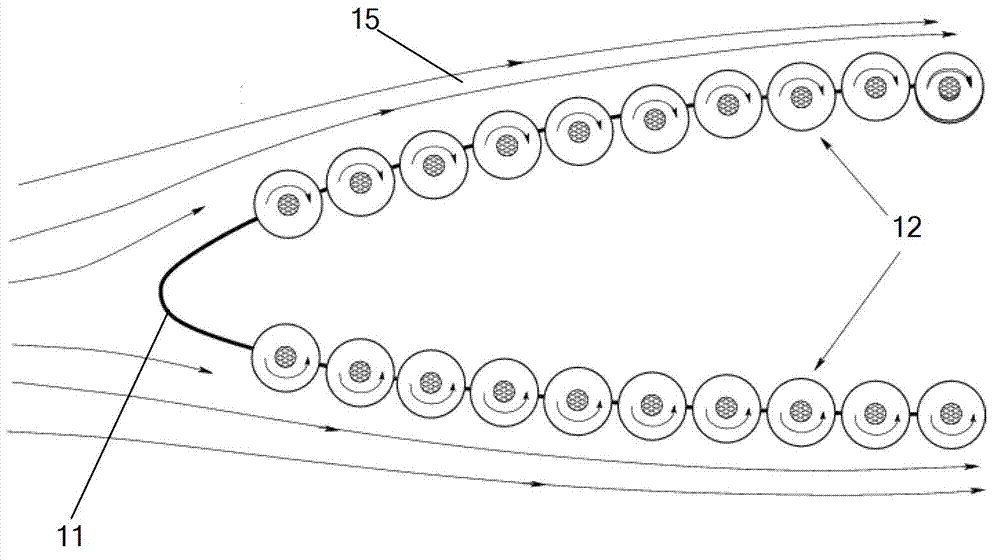

[0024] The novel surface drag-reducing structure of the present invention can be provided on a part of the surface of a high-speed moving object, such as a high-speed rail, an automobile, and the like.

[0025] The application environment of this embodiment is an ideal application environment for implementing the drag reducing structure of the present invention. Since most surfaces of the moving object are smooth and the movement is stable most of the time (without frequent stops and starts), the rotating body 14 can adopt a drum structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com