Semi-tower type medium-temperature separation biomass circulating fluidized bed boiler

A circulating fluidized bed and half-tower technology, which is applied in the field of half-tower medium-temperature separation biomass circulating fluidized bed boilers, can solve the problems of hindering combustion, difficult to burn out fuel, easy to catch fire, etc., to prevent slagging and bedding. The effect of preventing material agglomeration, controlling fouling and fouling, and preventing fouling and fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

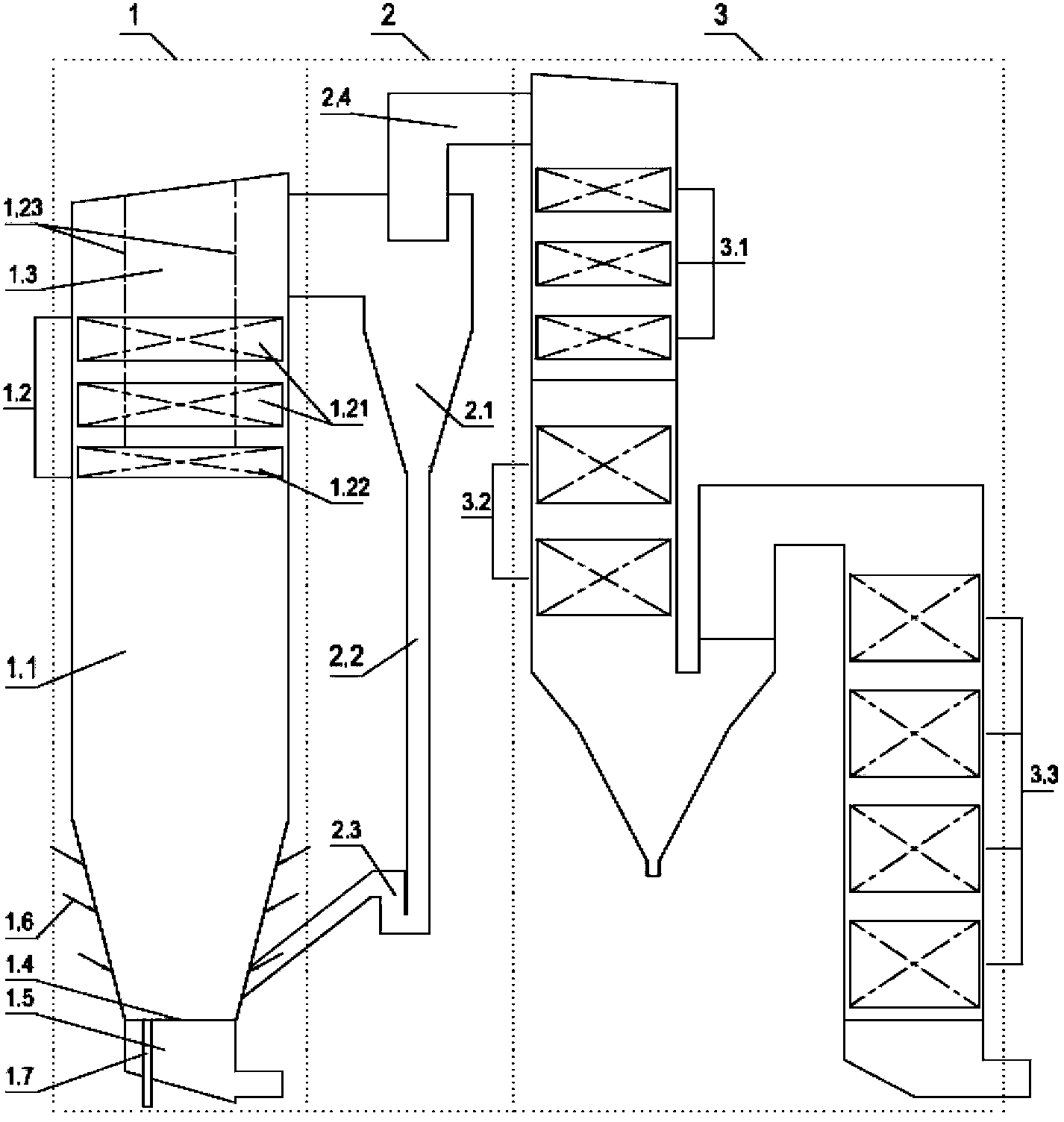

[0026] Biomass fuel enters the furnace 1.1 through the feeding device in front of the furnace, and the primary air is sent into the furnace 1.1 from the primary air chamber 1.5 at the bottom of the furnace through the air distribution device 1.4 as the primary combustion air and the fluidized medium of the materials in the furnace, and the secondary air 1.6 The lower part of the furnace is divided into three layers along the height direction, and each layer is arranged in parallel to ensure sufficient combustion air for fuel.

[0027] Biomass fuel ignites in the dense-phase zone at the lower part of the furnace, burns and releases most of the heat in an oxygen-deficient state, and the unburned volatile matter and carbon particles enter the dilute-phase zone of the furnace through the transition zone of the furnace, and are formed in the secondary air Further combustion in the oxidizing area generates high-temperature flue gas, and the SO in the flue gas 2 Reaction with alkali ...

Embodiment 2

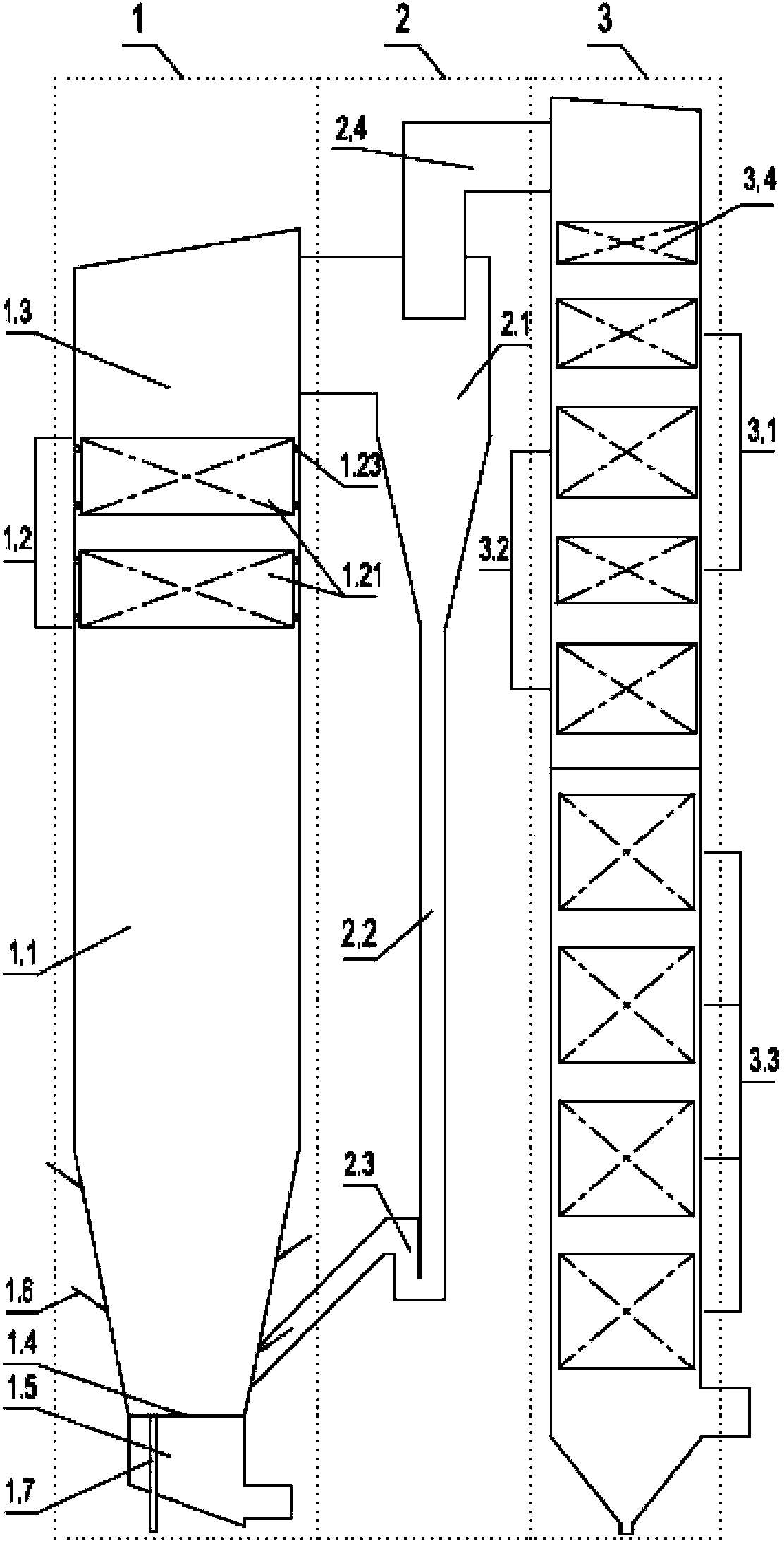

[0033] The overall layout of this embodiment is basically the same as that of Embodiment 1. The difference between the two is that only the convection heating surface 1.21 is arranged in the convection shaft 1.2 on the upper part of the furnace in this embodiment, and the convection heating surface 1.21 is suspended on the water wall through the support device 1.23 Up. Two layers of secondary air 1.6 are arranged on the water-cooled walls of the lower part of the furnace 1.1, and the staggered arrangement is adopted, so that under the disturbance of the staggered secondary air 1.6, the biomass fuel with low density forms a similar "S" in the process of the furnace. The shape of the trajectory prolongs its residence time in the high temperature zone of the furnace. The tail flue 3 is set as a single flue gas passage, and is provided with an evaporation heating surface 3.4, superheaters 3.1 arranged crosswise, economizers 3.2 and air preheaters 3.3 from top to bottom.

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com