Welding process evaluation method for first-grade nuclear container steel plate

A welding process and steel plate technology, which is applied in the field of welding process evaluation of steel plates for nuclear primary pressure vessels, and achieves the effect of wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

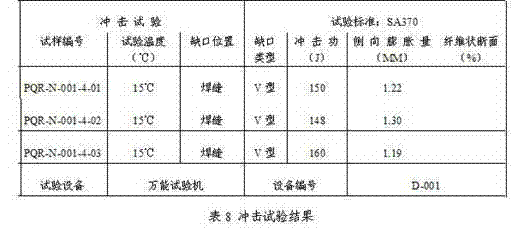

Examples

Embodiment Construction

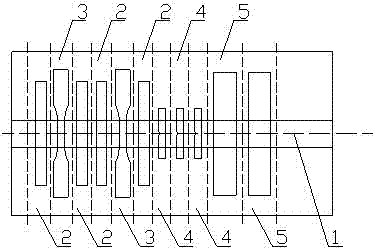

[0013] Firstly, cut the welding procedure qualification test piece with line drawing, the sample should be perpendicular to the longitudinal axis of weld 1, and the center line of the sample length should be on the center line of weld 1, and then mark the test piece on the test piece and the sample bag. sample number.

[0014] 1. Make tensile test specimen 3.

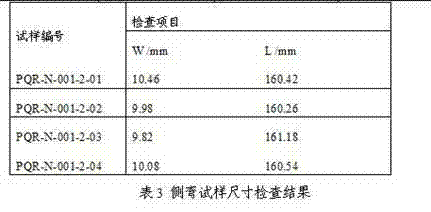

[0015] A) After the tensile sample 3 is made, the sample is then processed. Attention should be paid during processing. Before repairing the weld reinforcement, the test piece is allowed to be cold straightened. The weld reinforcement should be machined. Trimming to be flush with the base metal, the amount of processing should be as small as possible, in order to obtain approximately parallel surfaces as a principle, and process it to the required size. And mark the sample number on the sample and sample bag, and finally carry out dimensional inspection. The results of size inspection are shown in Table 1.

[0016] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com