Experimental method for fracture reorientation rule in oriented perforating and fracturing process

An experimental method and directional perforation technology, applied in the field of hydraulic fracturing, can solve the problems of large differences and affect the reliability of the test, and achieve the effect of high test reliability and accurate and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

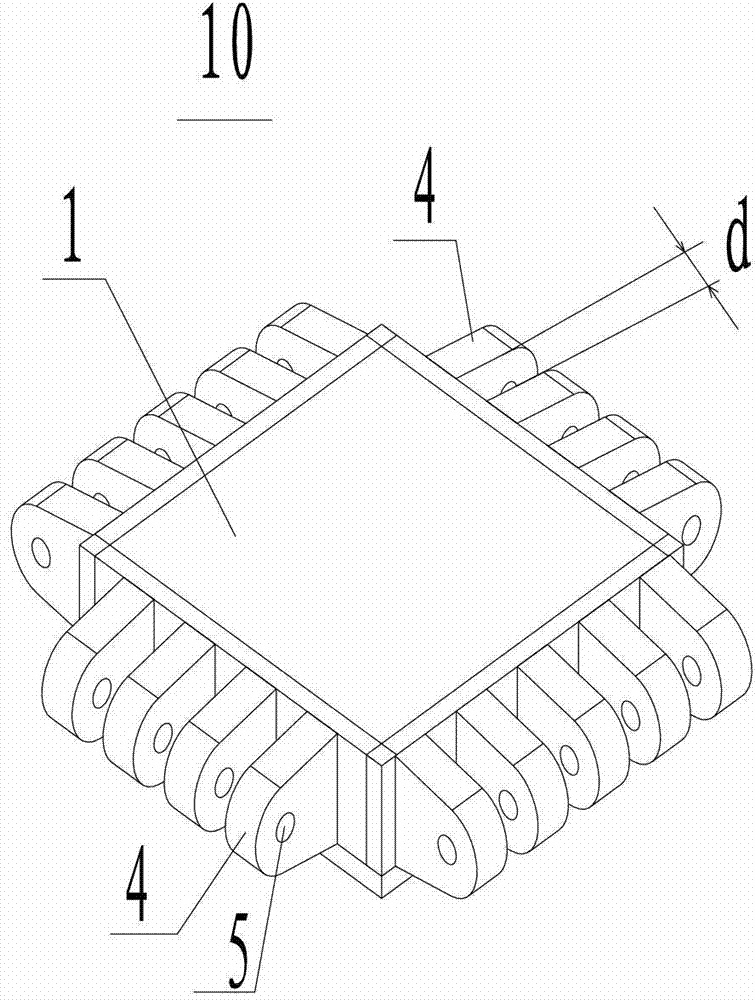

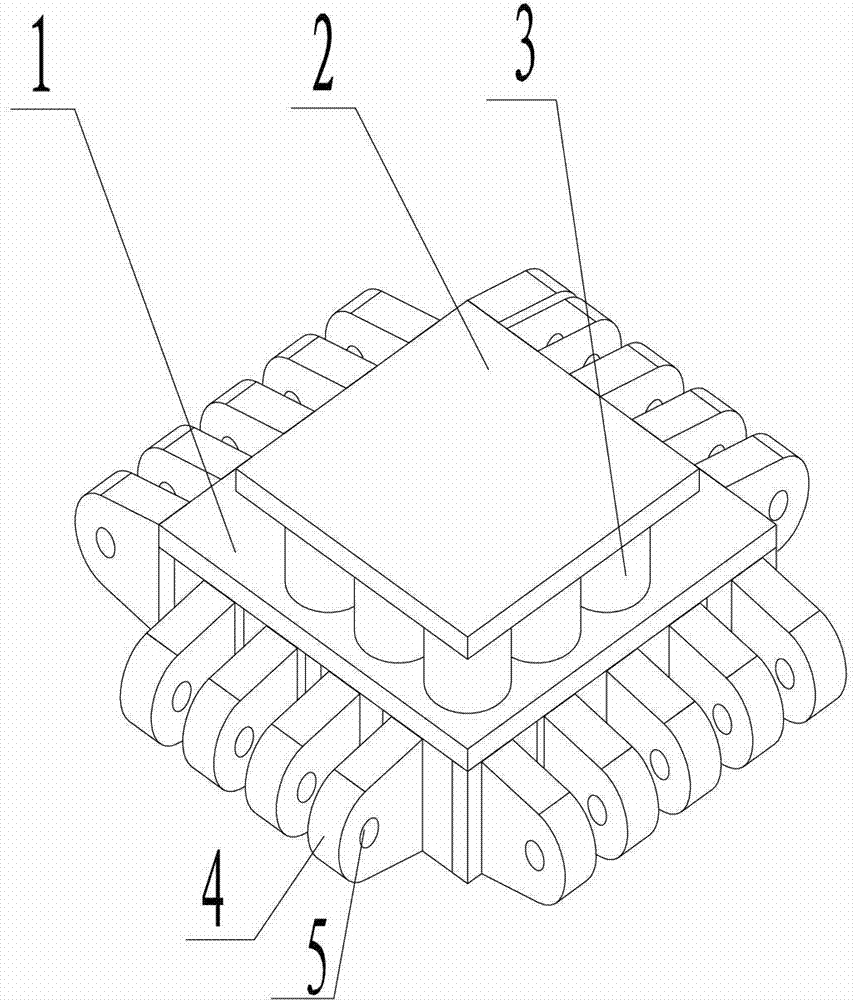

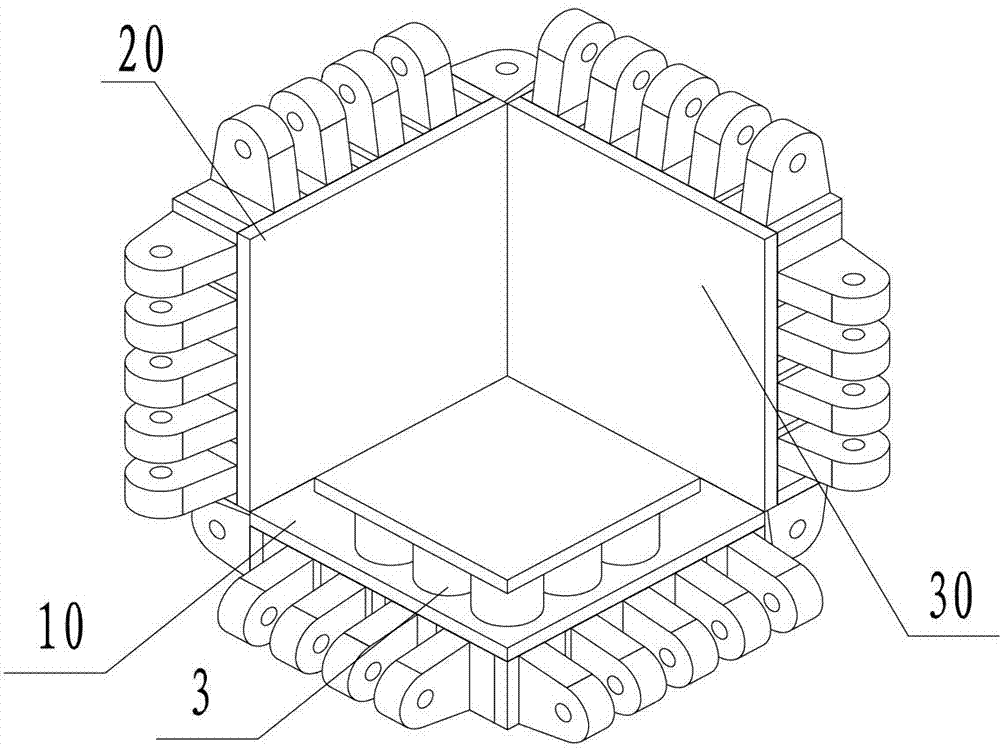

[0032] The present invention proposes an experimental method for research on directional perforation and fracturing fracture diversion. The experimental method includes:

[0033] A cube with a side length greater than or equal to 1m is used as a test piece and the test piece is made, and then under the condition of triaxial (three axes or three directions perpendicular to each other) stress loading, directional perforation and fracturing are carried out successively, and then The specimens were dissected to study the relationship between perforation direction and fracture orientation. The core outcrop is collected from the mine, and after mining, it is cut into cubes, the surface is trimmed, and the surface accuracy is controlled. The core outcrop cube greater than or equal to 1m is mainly to consider the radius and distance of fracturing fracture turning. Usually, the radius and distance of fracturing fracture turning are more than 0.5m. If the test piece is too small, it is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com