A sand mill that can automatically add defoamers and automatically test the dispersion effect

A technology of automatic adding and defoaming agent, applied in the field of sand mill, can solve the problems of accelerating the volatilization of defoaming agent, uncontrollable amount of defoaming agent, and poor defoaming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present application will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

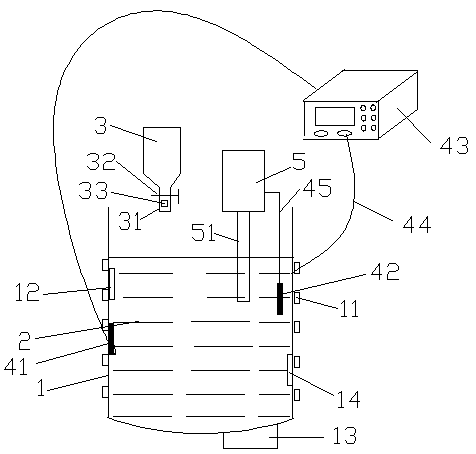

[0034] Such as figure 1As shown, a sand mill that can automatically add defoamers and automatically test the dispersion effect, including a ceramic grinding bucket 1, a circulating water pipe 11, a liquid level sensor 12, a controller 13, a temperature sensor 14, and a carbon nanotube conductive paste Material 2, defoamer storage tank 3, liquid outlet 31, solenoid valve 32, flow sensor 33, electrode a 41, electrode b 42, resistance meter 43, wire 44, telescopic rod 45, online viscosity meter 5 and rotor 51, etc. Main technical characteristics.

[0035] A sand mill that can automatically add defoamers and automatically test the dispersion effect, including a ceramic grinding barrel, carbon nanotube conductive paste, defoamer storage tank, dispersion effect tester and online viscosity tester.

[0036] There is a controller...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com