A hydraulic cylinder anti-lateral force performance test device

A technology of anti-lateral force and testing equipment, which is applied in the direction of measuring equipment, elastic testing, mechanical parts testing, etc., can solve problems such as high lateral force, dangerous accidents of operators, hydraulic cylinder damage, etc., and achieve test reliability High effect, high application precision and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

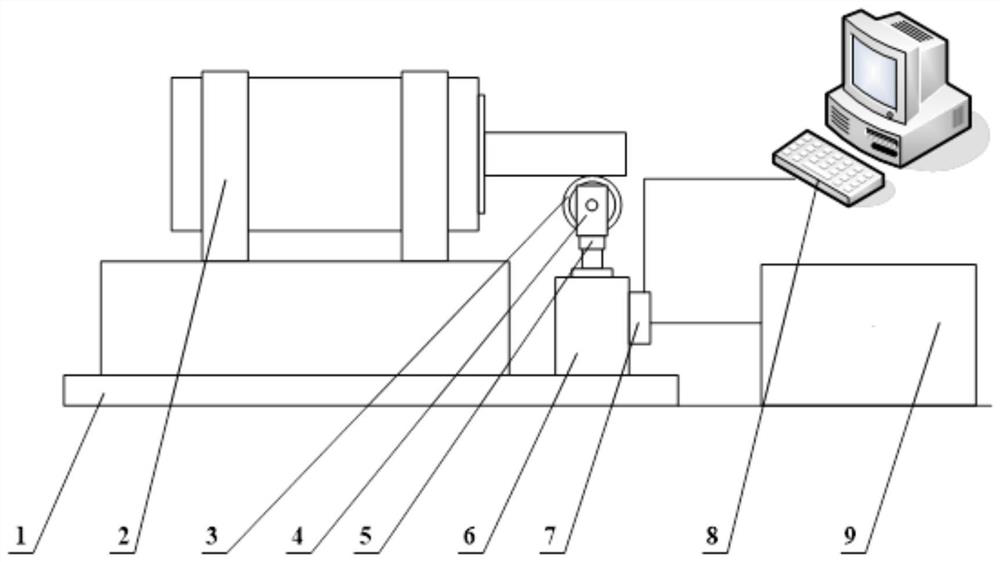

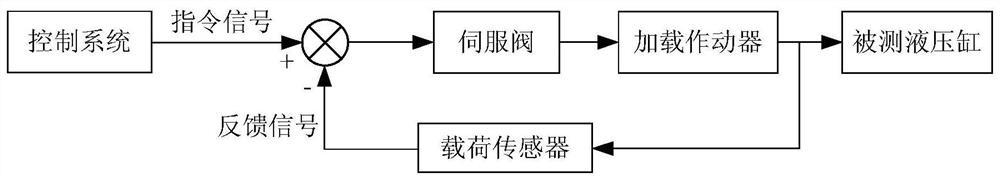

[0028] see figure 1 , a hydraulic cylinder anti-lateral force performance test device of the present invention, comprising a mounting base 1, a mounting bracket 2, a loading runner 3, a runner bracket 4, a load sensor 5, a loading actuator 6, a servo valve 7, a control System 8, oil source 9; the installation base 1 is placed horizontally and fixed, and the installation bracket 2 is fixed on one side of the installation base 1 to support and fix the hydraulic cylinder to be tested; the other side of the installation base 1 is fixed on the loading actuator 6, and the loading The end of the piston rod of the actuator 6 is connected to the load sensor 5, and the end of the load sensor 5 away from the piston rod of the loading actuator 6 is connected to the runner bracket 4; the loading runner 3 is erected and fixed on the runner bracket 4 through its rotating shaft , the loading runner 3 is pressed against the piston rod of the hydraulic cylinder to be tested.

[0029] The servo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com