Perpendicular magnetic recording medium

A technology of perpendicular magnetic recording and magnetic recording layer, applied in the direction of magnetic recording, data recording, recording information storage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

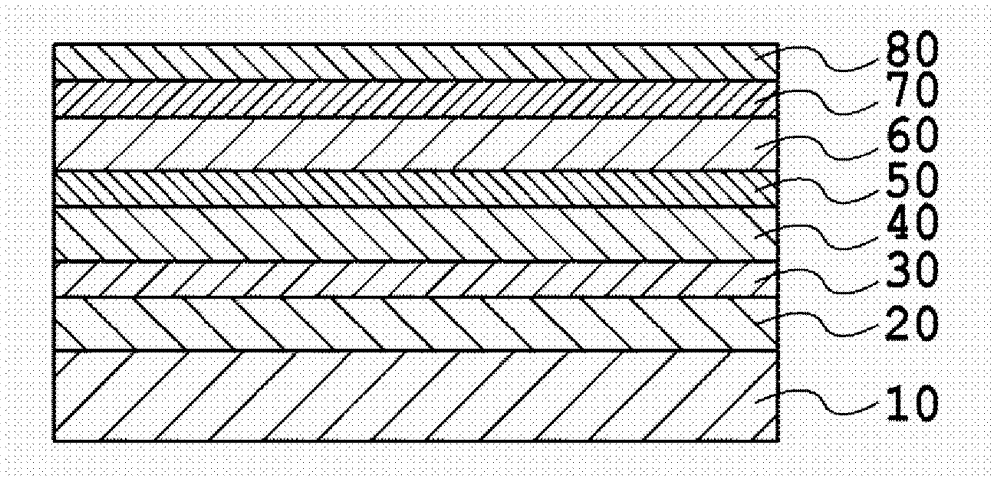

[0040] As the non-magnetic substrate 10 , an Al substrate (S13 aluminum substrate manufactured by Fuji Electric Device Technology Co., Ltd.) having a smooth surface subjected to Nip plating was prepared and washed. The cleaned non-magnetic substrate 10 is introduced into a DC magnetron sputtering device. Next, a Co54Fe9Ta6Zr target (consisting of 54at% Fe, 9at% Ta, 6at% Zr, and the remainder of Co on the basis of all atoms. The same applies hereinafter) was used to form a film with a thickness of 30nm in Ar gas at a pressure of 0.67Pa. Co54Fe9Ta6Zr amorphous soft magnetic backing layer 20. Next, a Ni20Cr2Si first base layer 30 with a film thickness of 6 nm was formed using a Ni20Cr2Si target in Ar gas at a pressure of 0.67 Pa. The obtained Ni20Cr2Si film has fcc structure. Next, in Ar gas at a pressure of 4.0 Pa, an Ru intermediate layer 40 with a film thickness of 8 nm was formed using a Ru target. Next, a Co26Cr2W second base layer 50 was formed using a Co26Cr2W target in...

Embodiment 2

[0042] A perpendicular magnetic recording medium was produced by the same procedure as in Example 1 except that the composition of the target was changed to Co38Cr2W when forming the second base layer 50 .

Embodiment 3

[0044] A perpendicular magnetic recording medium was produced by the same procedure as in Example 1 except that the composition of the target was changed to Co42Cr2W when forming the second base layer 50 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com