Method for manufacturing an inner covering assembly on a member of a forming tool

A technology of covering parts and mechanical parts, which is applied in the direction of motor vehicles, household appliances, household components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

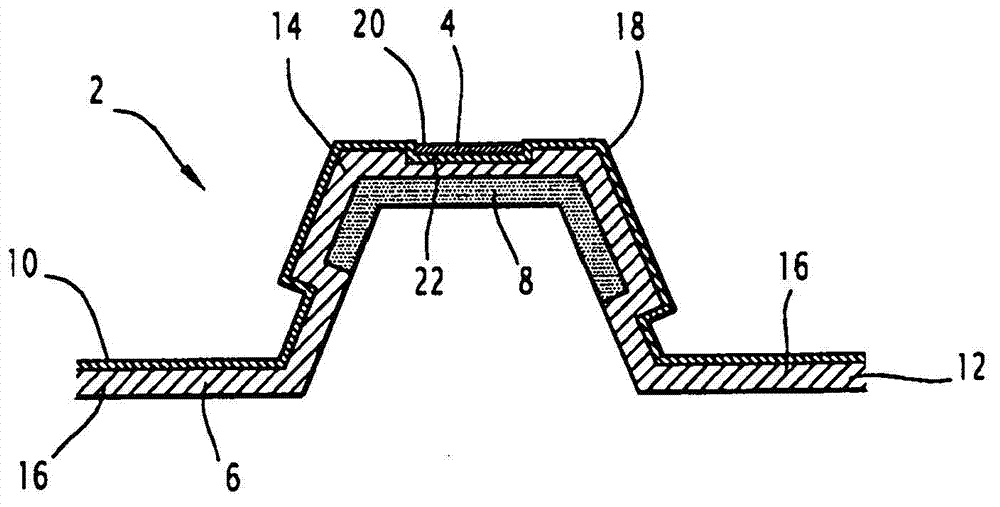

[0013] figure 1 is a cross-sectional view of an interior cover 2 with components for a motor vehicle. The inner cover 2 is especially useful as a finish for a dashboard of a motor vehicle.

[0014] The cross-sectional shape of the inner cover 2 generally corresponds to that of a cover, having a central raised portion 14 bordered on each side by a straight cross-sectional portion 16 .

[0015] Here, the inner cover 2 has three components, namely a first component formed by the trim 4 , a second component formed by the composite panel 6 , and a third component forming the insert 8 . Obviously, the cover can only have the first two components 4,6. Preferably, the decorative element 4 is a sheet made of polycarbonate material, in particular having a thickness of about 400 micrometers. The trim part 4 is provided with a first appearance surface 20 intended to be visible in the assembled state of the interior cover part 2 and a second connection surface 22 which ensures the conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com