Uniformly sprinkling device

A technology of sprinkling and uniformity, which is applied in the direction of feeding device, dissolving, mixing machine, etc., can solve the problems that the hopper cannot achieve uniform feeding, low cost performance, and complexity, and achieve convenient and fast mixing, soft reaction process and fast reaction Effect

Inactive Publication Date: 2012-11-21

苏州市华元化工有限公司

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Nowadays, the commonly used feeding methods are usually direct feeding or feeding through a hopper, but ordinary hoppers cannot achieve uniform feeding at all.

And some devices with better feeding effect are more complicated, expensive, inconvenient to install, and low in cost performance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

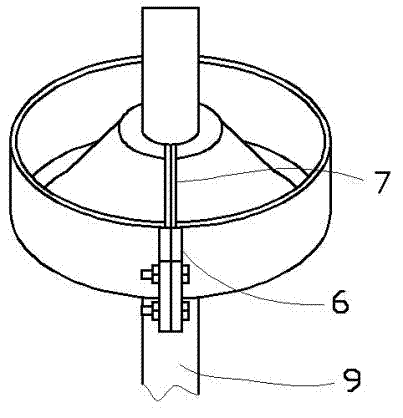

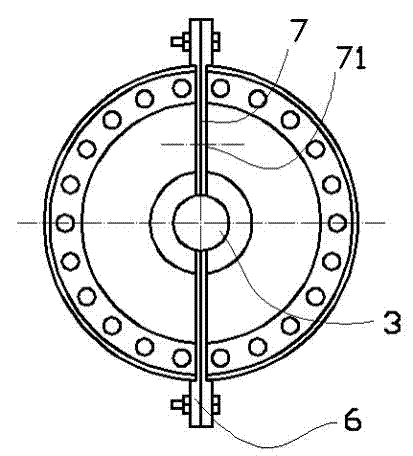

[0022] Embodiment 2 During installation, as long as the uniform sprinkling device is composed of two symmetrical parts, placed on the middle main column 9, and the mounting screws are fastened, the installation and disassembly are particularly convenient.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

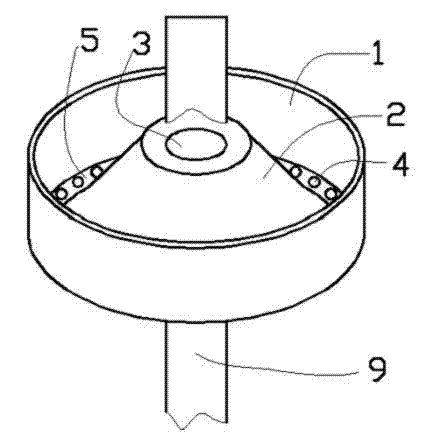

Login to View More Abstract

The invention provides a uniformly sprinkling device, which belongs to the technical field of chemical production. The uniformly sprinkling device is centrosymmetric; the periphery of the device is a cylindrical wall, and the central part of the device is a protruding cone frustum; the center of the cone frustum is a perforative cylindrical bore; a circular ring bottom surface is located between the cone frustum and the bottom surface of the cylinder wall, and a plurality of geometric holes penetrating the circular ring bottom surface are uniformly distributed in the circular ring bottom surface. The uniformly sprinkling device is mounted in a mixer or a reaction kettle with a central main post; the device has a simple structure, can be easily installed on the post without a power unit, can evenly add solid or liquid materials into a material chamber, allows mixing of the materials to be more convenient and faster or reaction of the materials in the reaction kettle to be more quickly and milder.

Description

technical field [0001] The invention belongs to the technical field of chemical production, and in particular relates to a uniform spraying device. Background technique [0002] In chemical production, no matter the reaction kettle or the mixer, it is often necessary to mix the materials evenly. According to the different mixing materials, the mixing speed and method vary widely. Stirring is a commonly used means of speeding up the mixing, but good mixing effects often require a long time. Time, the reaction of materials in the reactor faces the same problem, a good reaction effect and comprehensiveness often take a long time, [0003] However, whether it is stirring or the reaction and mixing of materials, it has a huge relationship with its feeding device. The more uniform the feeding, the more convenient and fast the mixer is to mix, and the faster the reaction of the materials in the reactor is, the softer it is, and the higher the safety. Nowadays, the commonly used fe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01F15/02B01J4/00

Inventor 徐永华

Owner 苏州市华元化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com