A battery fixing bracket

A battery fixing and battery technology, which is applied in the direction of electric power devices, power devices, transportation and packaging, etc., can solve the problems of difficult fixing and tightening of bolts, time-consuming and labor-intensive assembly, and lack of connecting components, etc., so as to facilitate disassembly and maintenance, reduce wear, Realize the effect of quick change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

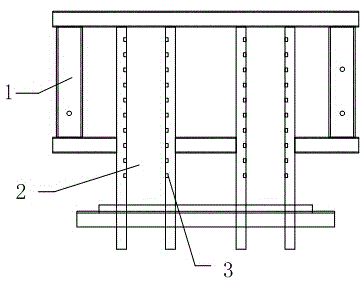

[0019] Such as figure 1 The shown battery fixing bracket includes a battery bottom plate support assembly 1, which is different in that: battery guide components are distributed on the battery bottom plate support assembly 1 adopted in the present invention, and the ends of the battery guide components A battery box lock assembly is provided.

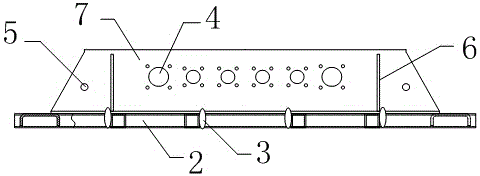

[0020] In view of a preferred embodiment of the present invention, the battery guide assembly used includes a guide rail 2 , and rollers 3 are distributed on the guide rail 2 in order to push the battery to an accurate position. further combined figure 2 It can be seen that connecting plates 7 are distributed on the battery box lock assembly, and battery wiring assemblies 4 are arranged on the connecting plates 7 . For accurate positioning of the battery assembly, battery positioning holes 5 are distributed on both sides of the battery box lock assembly. Moreover, the battery box lock assembly is provided with a battery positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com